NC tool rack

A technology for placing racks and tools, applied in tool storage devices, manufacturing tools, metal processing machinery parts, etc., can solve problems such as scratches on the surface of the tool bar of the CNC tool, damage to the surface of the CNC tool, and influence on the accuracy of the CNC tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

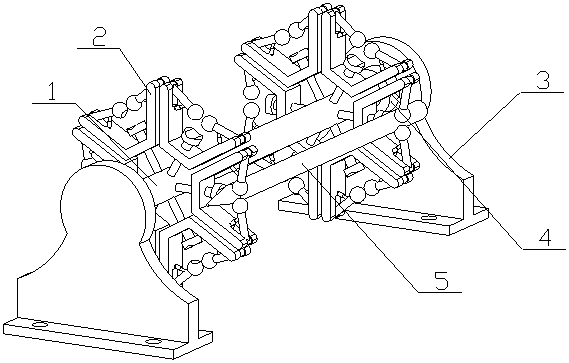

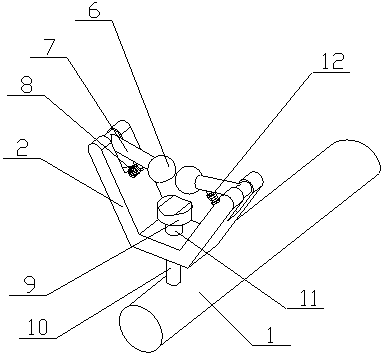

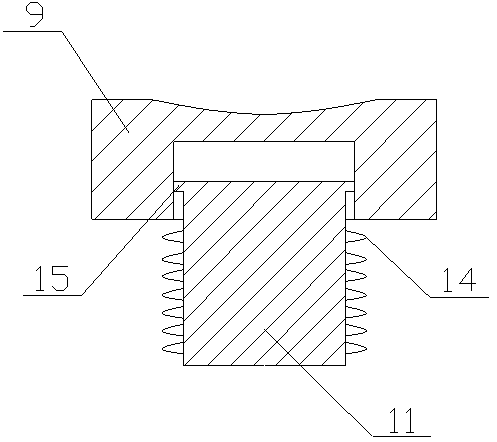

[0019] A numerical control tool placement frame of the present invention is realized in this way: a numerical control tool placement frame of the present invention consists of a central column (1), a support frame (2), a fixed seat (3), a bearing (4), and a fixed ball (6) , rotating rod (7), fixed boss (8), placing platform (9), connecting column (10), support rod (11), tension spring (12), pressure spring (14) and limit ring (15) The two ends of the central column (1) are respectively connected by bearings (4) and two fixed seats (3), the two fixed seats (3) are parallel, and the fixed seats (3) are provided with The fixing hole, the fixing seat (3) is narrow at the top and wide at the bottom, multiple sets of the connecting columns (10) are fixed on the side of the central column (1), the number of the connecting columns (10) is at least three groups, more The groups of connecting columns (10) are equidistantly distributed in a ring, and each group of connecting columns (10)...

Embodiment 2

[0023] The difference between this embodiment and Embodiment 1 is: there are multiple sliding grooves (13) on the outer surface of the central column (1), which correspond to multiple sets of connecting columns (10), and the sliding grooves (13) ) extends axially along the central column (1), and a sliding block is placed on the other end of the connecting column (10), and the sliding block is placed in the corresponding sliding groove (13); during use, the two in a group can be adjusted The distance between the two support frames (2) is suitable for CNC tools (5) of different lengths;

[0024] The fixed seat (3) is designed with a narrow top and a wide bottom, the bottom support is more stable, the support area is large, and the upper part can place a longer tool without being limited by the distance between the two fixed seats (3);

[0025] The other end of the support rod (11) is designed with a limiting convex ring, and the limiting groove is designed with a limiting bar n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com