A small garbage disposal transfer station

A technology of garbage disposal and transfer station, which is applied in the direction of garbage collection, garbage transmission, loading/unloading, etc. It can solve the problems of destroying production and living safety, polluting the environment, and not being able to realize photolysis and adsorption of odor treatment, so as to ensure coherence and reasonableness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

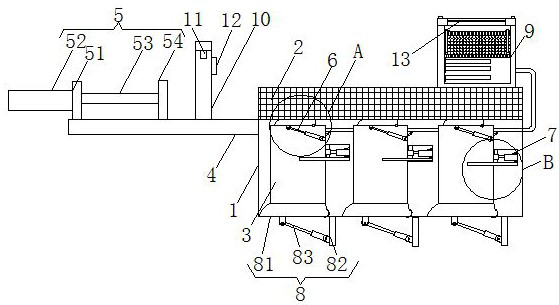

[0023] Embodiment 1: A small-scale garbage processing transfer station, including a processor body 1, a classification push mechanism 5, an inlet mechanism 6, a compression mechanism 7, a discharge mechanism 8, and a deodorization and ventilation mechanism 9, and the processor body 1 provides a mechanism and The installation place of the device, the upper wall of the processor body 1 is provided with a strip groove 2, the strip groove 2 is convenient for pushing the garbage, and the inside of the processor body 1 is uniformly equipped with a processing chamber 3 to realize the storage of garbage, and the processor The upper end of the left wall of the body 1 is provided with a support plate 4, which provides a support and installation platform, the upper surface of the support plate 4 is flat with the bottom surface of the strip groove 2, and the classification push mechanism 5 is correspondingly arranged on the upper wall of the support plate 4 On the left side, inlet mechanis...

Embodiment 2

[0027] The difference between this embodiment and Embodiment 1 is:

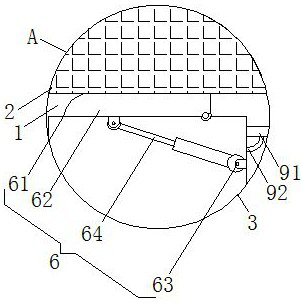

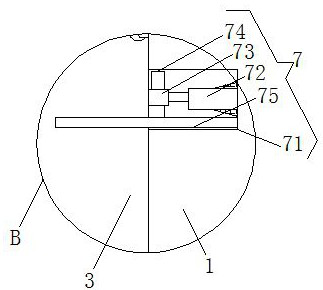

[0028] In this embodiment, the classification push mechanism 5 includes a vertical plate 51, a hydraulic pump 52, a telescopic column 53 and a material pushing plate 54. Fixedly connected in the wall installation port of the vertical plate 51, the hydraulic oil output port of the hydraulic pump 52 communicates with the oil inlet port of the telescopic column 53, the pusher plate 54 is arranged on the right part of the telescopic end of the telescopic column 53, and the inlet mechanism 6 includes an inlet 61. The inlet sealing plate 62, the U-shaped plate 63 and the electric telescopic rod 64, the inlet 61 is respectively arranged on the top wall of the processing chamber 3, and all communicate with the strip groove 2, and the right end of the inlet sealing plate 62 is hinged by a hinge On the right wall of the entrance 61, and corresponding to the entrance 61, the U-shaped plates 63 are respectively arranged ...

Embodiment 3

[0031] The difference between this embodiment and Embodiment 1 is:

[0032] In the present embodiment, the deodorizing and ventilating mechanism 9 includes a ventilating main cavity 91, a branch pipe 92, a deodorizing box 93, an ultraviolet tube 94, a fixed leak plate 95, a fixed screw 96, a movable leak press plate 97 and an activated carbon small The ball 98 and the ventilation main cavity 91 are arranged inside the processor body 1, the air port of the ventilation main cavity 91 is connected with the corresponding processing cavity 3 gas ports through the branch pipe 92, and the deodorization box 93 is arranged on the processor body 1 On the wall, the upper end of the deodorizing box 93 is an opening mechanism, and the ventilation opening at the bottom of the side wall of the deodorizing box 93 is connected to the ventilation opening of the main ventilation channel 91 through a conduit, and the ultraviolet tubes 94 are installed on the sides of the deodorizing box 93 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com