A control system and control method for diesel engine cylinder head transmission

A control system and diesel engine technology, applied in household refrigeration devices, applications, conveyors, etc., can solve the problems affecting the processing of diesel engine cylinder heads, high labor intensity of staff, and large heat of diesel engine cylinder heads, etc., to improve the efficiency of heat dissipation and cooling, The effect of improving conveying efficiency and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

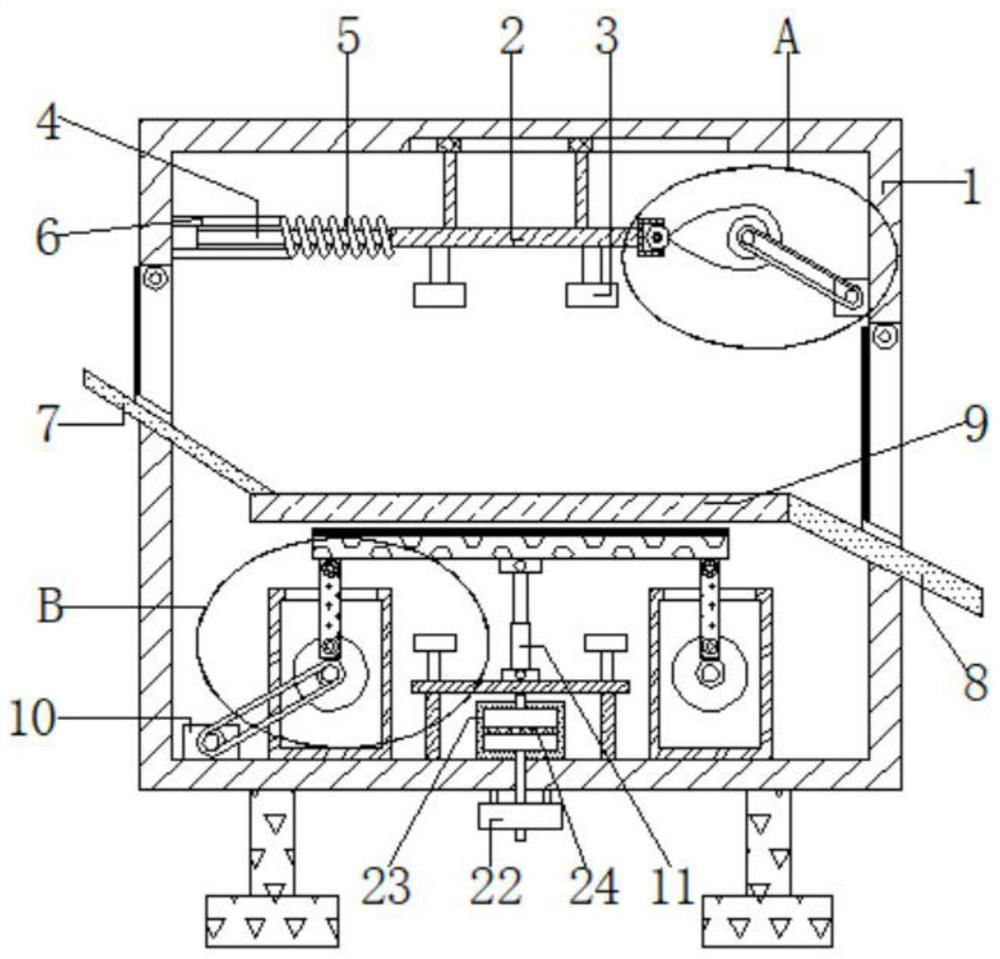

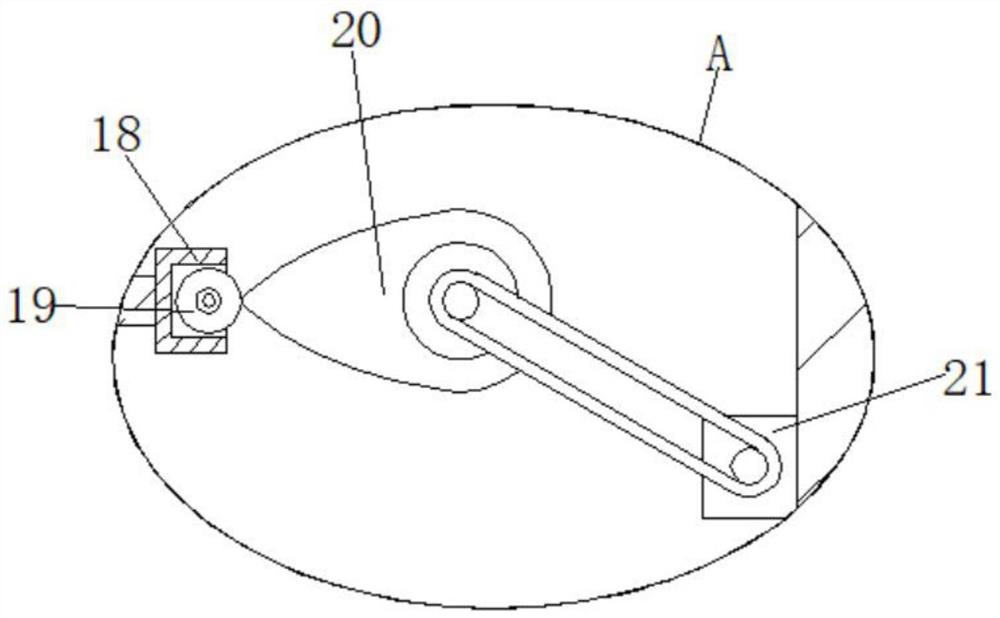

[0024] Example 1, such as Figure 1-4 Shown:

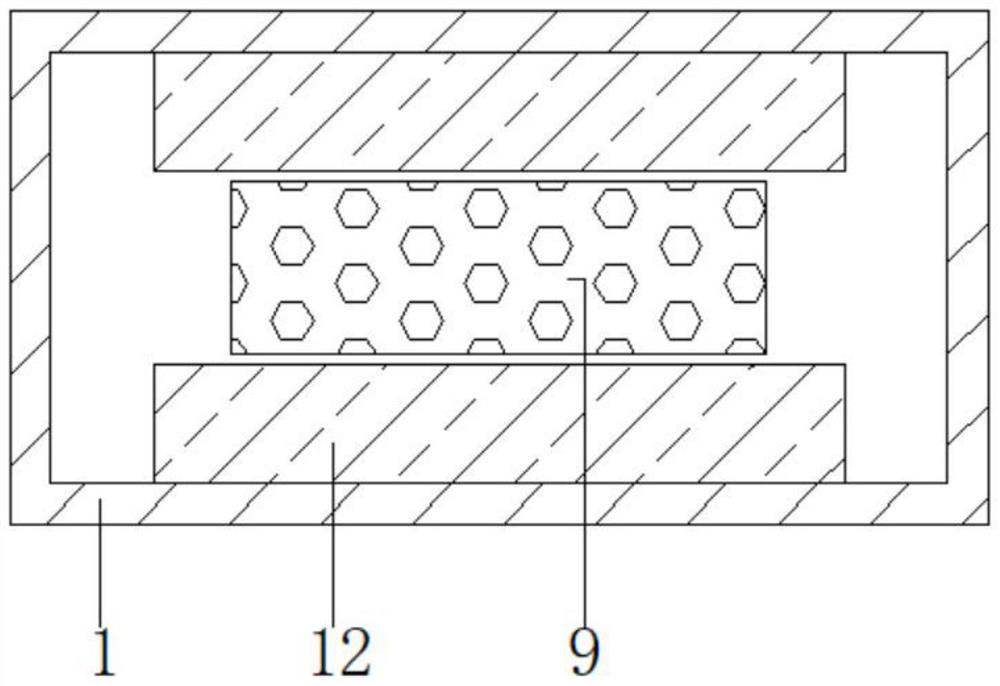

[0025] A control system for diesel engine cylinder head transmission, comprising a box body 1, the left and right side walls of the box body 1 are respectively provided with a material inlet and a material outlet, and the inner cavity of the box body 1 is provided on the front wall and the rear wall. A support plate 9 is fixedly connected respectively, and the top of the support plate 9 is fixedly connected with a feed swash plate 7 near the left side, the top of the feed swash plate 7 is fixedly connected with the bottom of the inner cavity of the feed port, and extends to the box Outside the body 1, the bottom of the support plate 9 near the right side is fixedly connected with a discharge sloping plate 8, so that the diesel engine cylinder head can be conveniently fed and transported and discharged, and the bottom of the discharge swash plate 8 is connected to the outlet. The bottom of the inner cavity of the feed port is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com