Material conveying mechanism and material conveying method

A technology of material transfer and conveyor belt, which is applied in the assembly field of the workshop transportation line, and can solve the problems of easy wear and tear of the conveyor belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

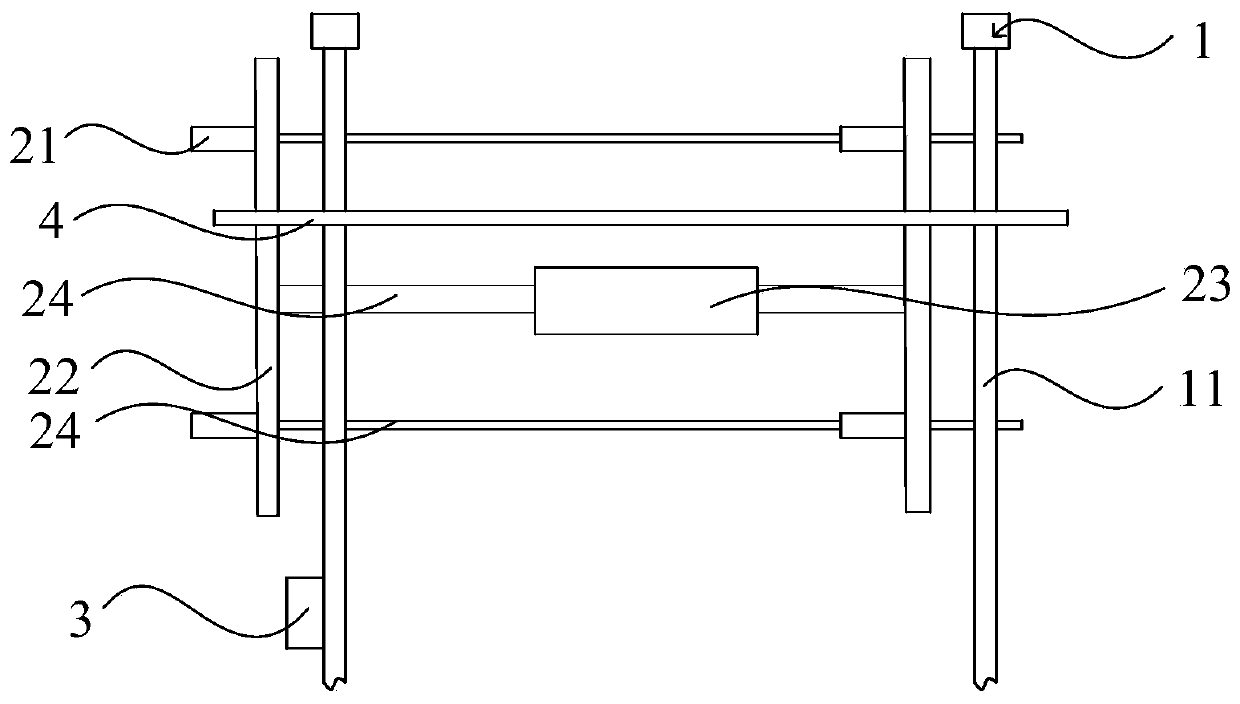

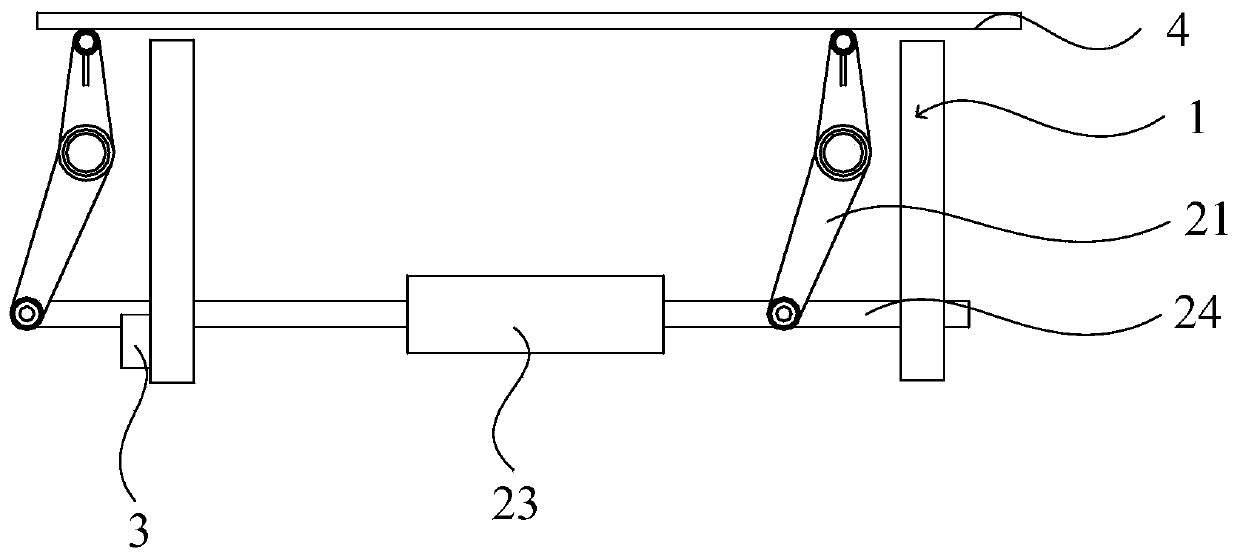

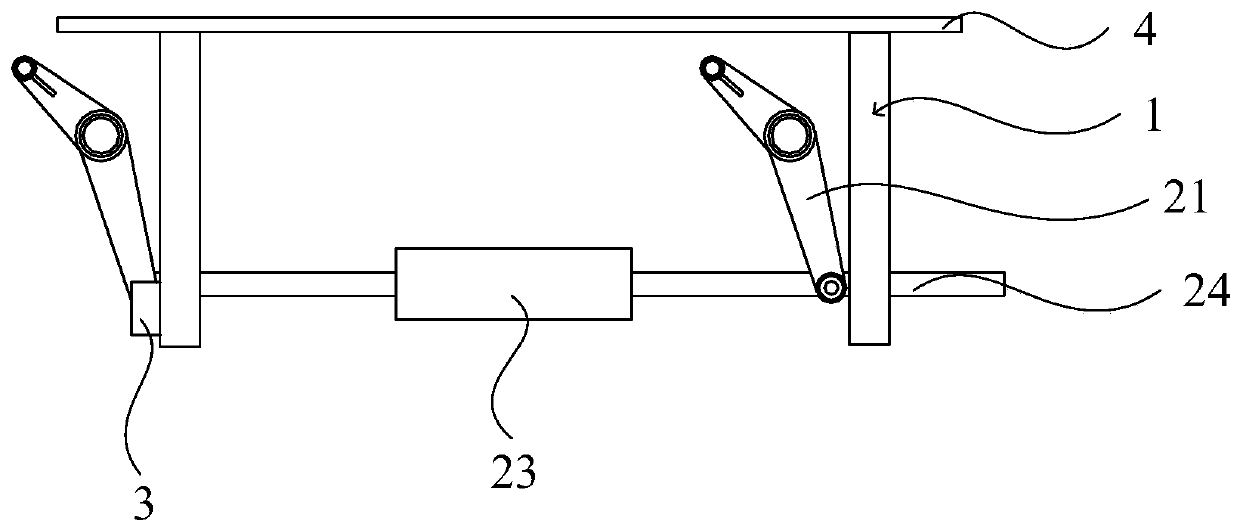

[0042] This embodiment provides a material transfer mechanism, which is used for the transfer of workpieces, and is especially suitable for the transfer of long workpieces. Such as Figure 1-3 As shown, the feeding mechanism includes a conveying device, a lifting device and a control device 3 .

[0043] The conveying device includes a plurality of conveying assemblies 1 arranged at intervals along the direction perpendicular to the conveying device's conveying direction, any conveying assembly 1 includes a conveying belt 11, and the conveying belt 11 can rotate cyclically. It should be noted that the specific structure of the conveying device and the method of rotating the conveying belt 11 belong to the prior art in the field, and will not be repeated here.

[0044] The lifting device is arranged close to the conveying devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com