Application of pyrogallic acid in silicon dioxide polishing

A technology of pyrogallic acid and silicon dioxide, which is applied in the direction of polishing compositions containing abrasives, etc., can solve problems such as the inability to remove butterfly defects and increase the production cost of polishing fluids

Active Publication Date: 2020-07-07

ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this will increase the production cost of the polishing liquid

On the other hand, complete

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

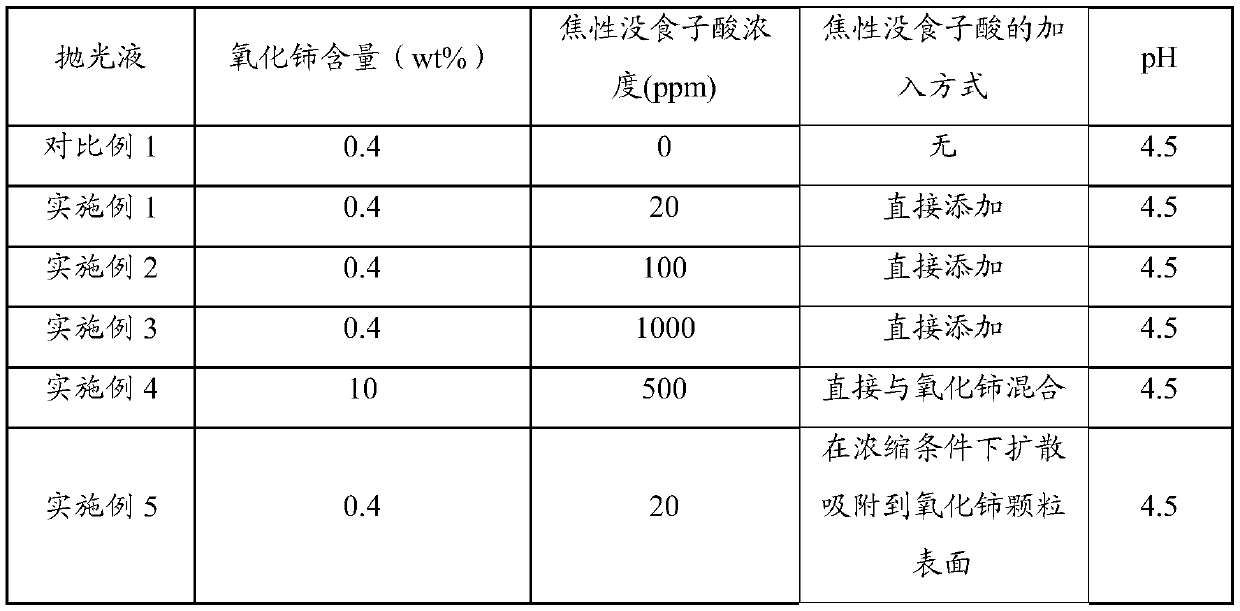

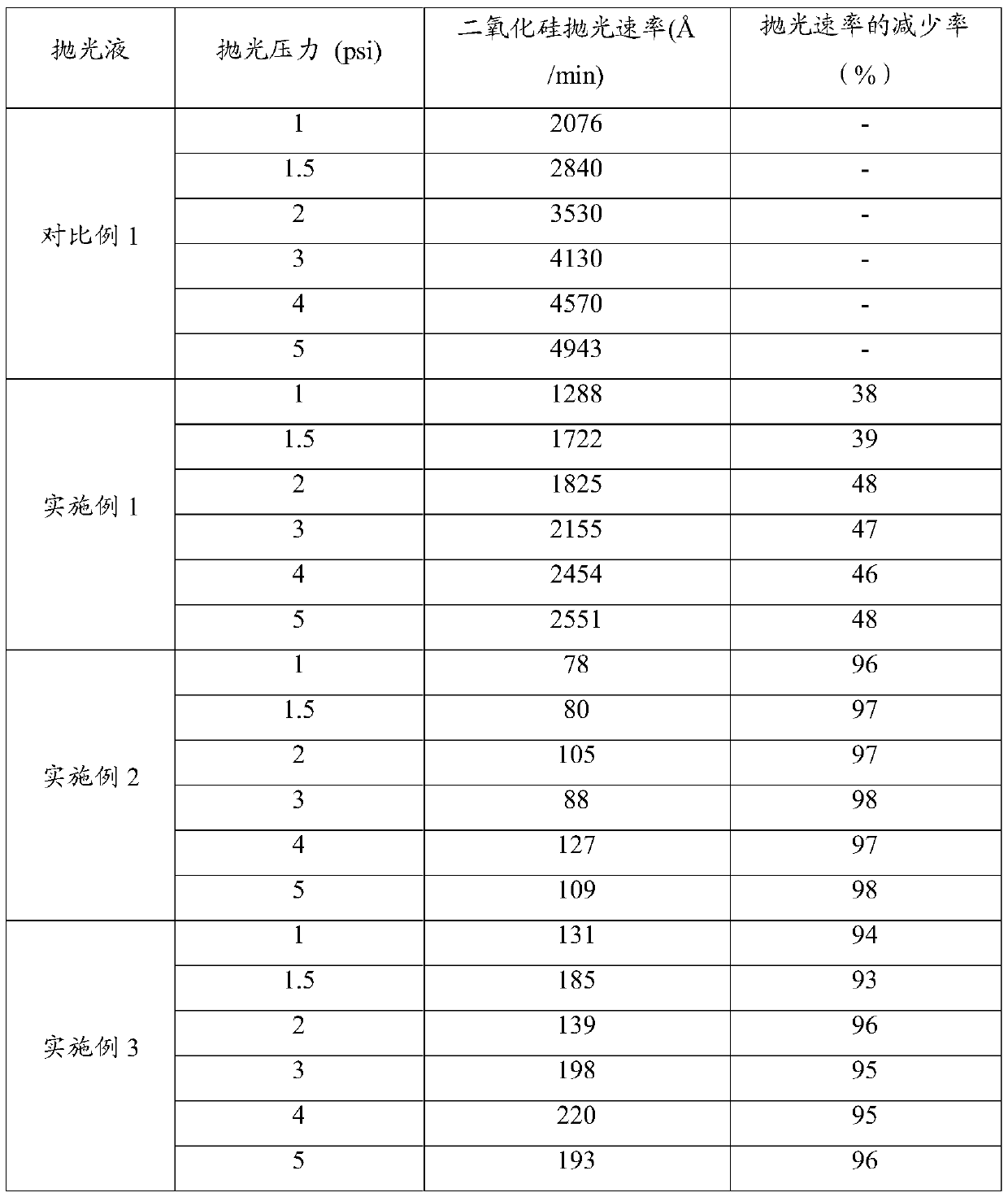

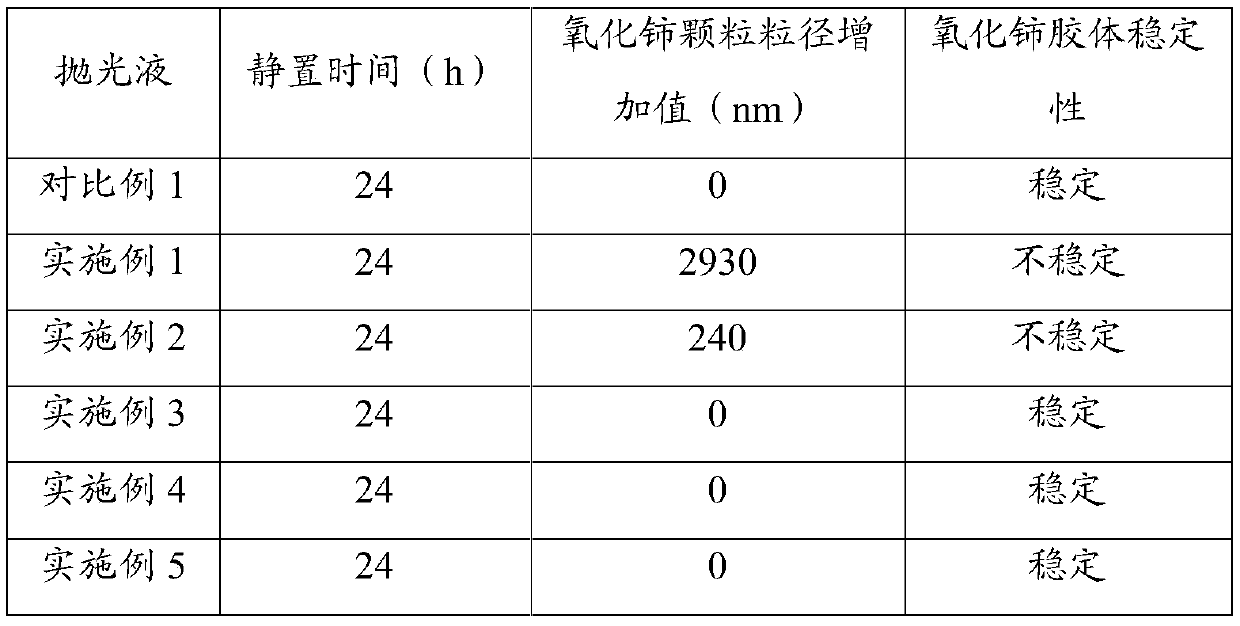

The invention discloses an application of pyrogallic acid in silicon dioxide polishing. The pyrogallic acid is matched with a chemical mechanical polishing solution for use, wherein the chemical mechanical polishing solution comprises cerium oxide grinding particles, the concentration of the pyrogallic acid is 20-1000 ppm, and the pH value of the chemical mechanical polishing solution is 4.5. By adding pyrogallic acid into the chemical mechanical polishing solution, the polishing rate of silicon dioxide can be properly inhibited, so that butterfly defects generated on the surface of silicon dioxide in the polishing process are avoided, and the quality of a polished product is improved.

Description

technical field [0001] The invention relates to the field of chemical mechanical polishing, in particular to the use of pyrogallic acid in silicon dioxide polishing. Background technique [0002] Chemical Mechanical Polishing (CMP) consists of chemical action, mechanical action, and a combination of both. It usually consists of a grinding table with a polishing pad, and a grinding head for carrying the wafer. The grinding head holds the wafer and presses the front side of the wafer against the polishing pad. When chemical mechanical polishing is performed, the grinding head moves linearly on the polishing pad or rotates in the same direction as the grinding table. At the same time, the slurry containing abrasive particles is dripped onto the polishing pad, and spreads on the polishing pad due to centrifugal action. The wafer surface is globally planarized under the dual action of mechanical and chemical. [0003] Cerium oxide is an important abrasive for CMP polishing fl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09G1/02

CPCC09G1/02

Inventor 李守田尹先升贾长征王雨春

Owner ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com