Conveyor system for transporting goods via conveyor belt or the like

A conveyor system and conveyor belt technology, applied in the field of conveyor systems, can solve problems such as increased structural cost, low tensile strength, and conveyor belt wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

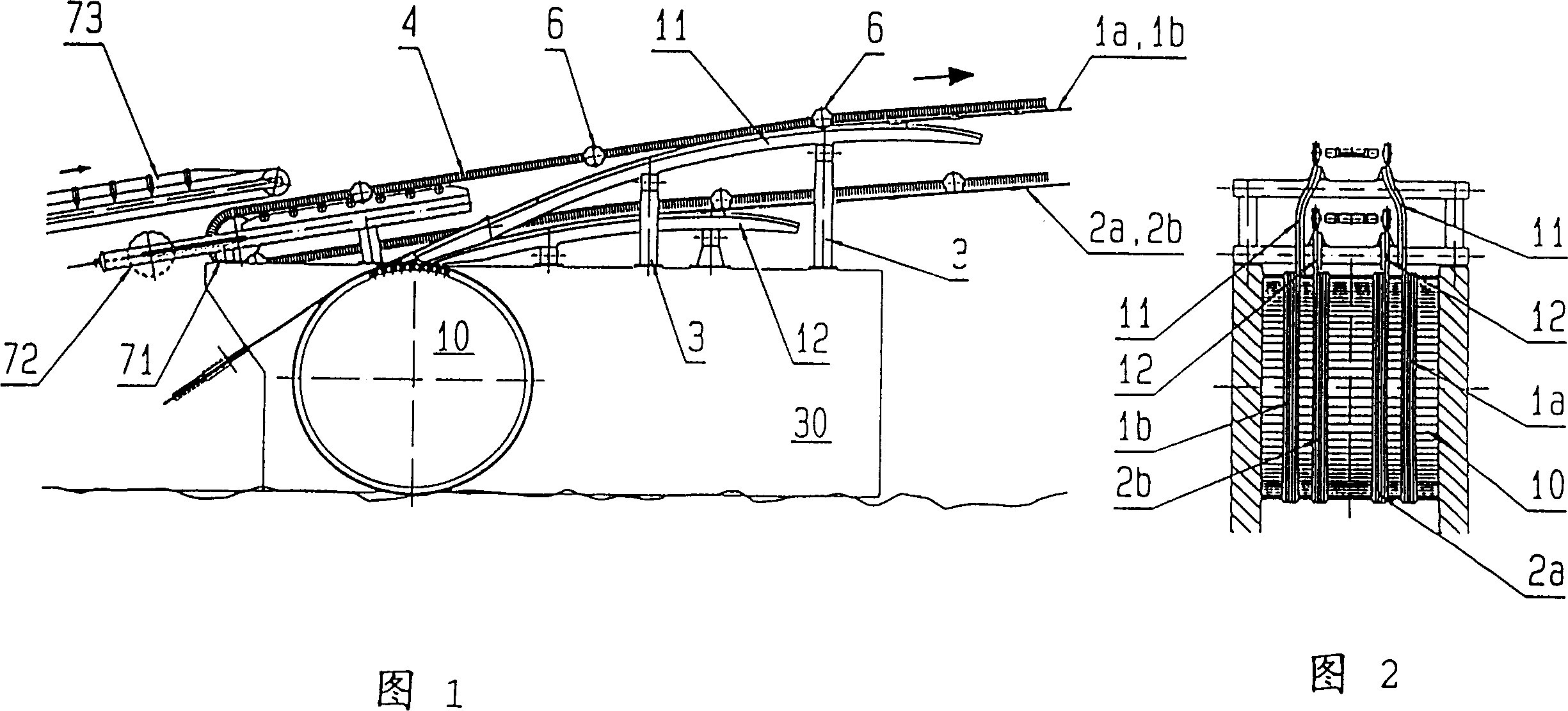

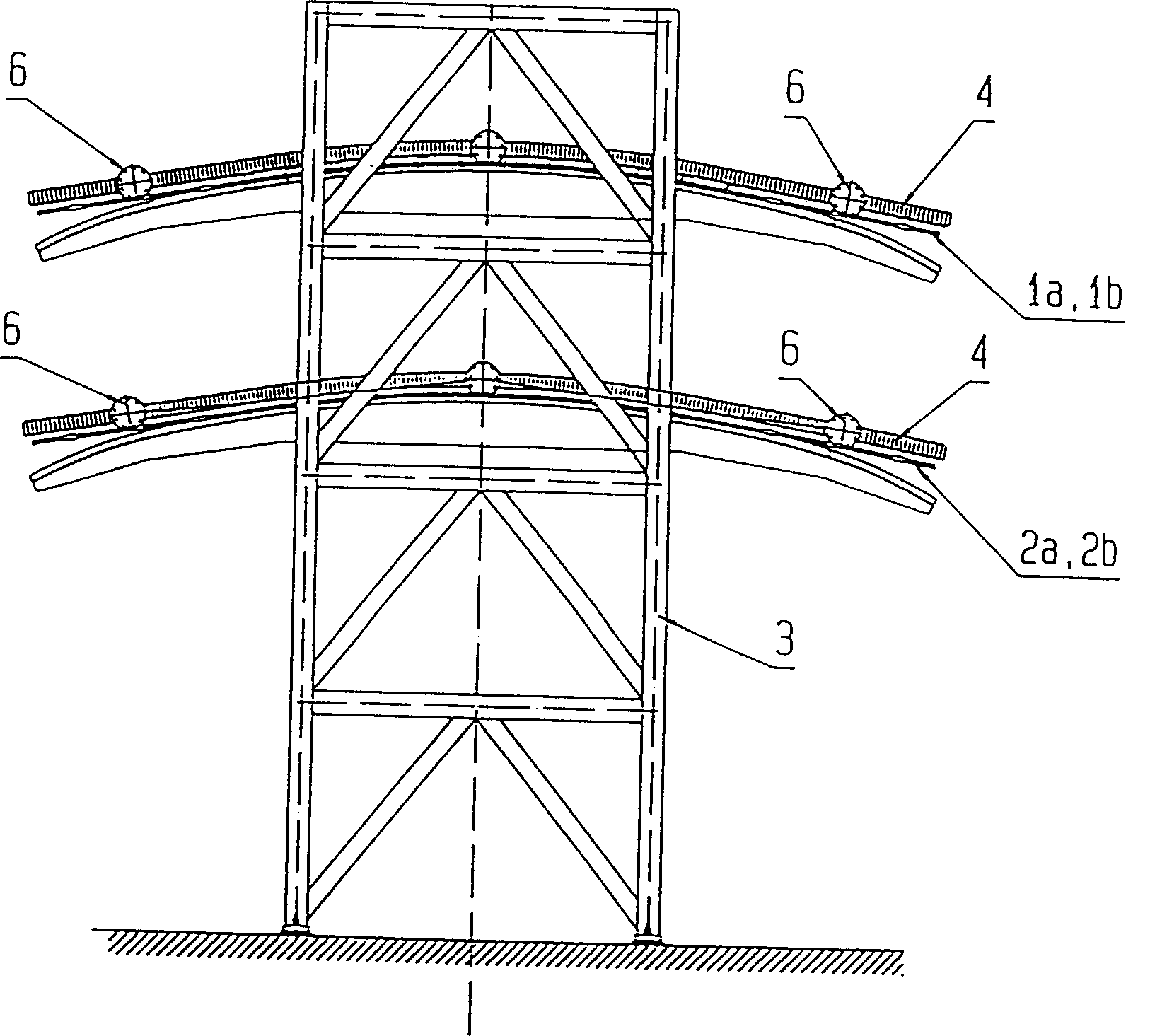

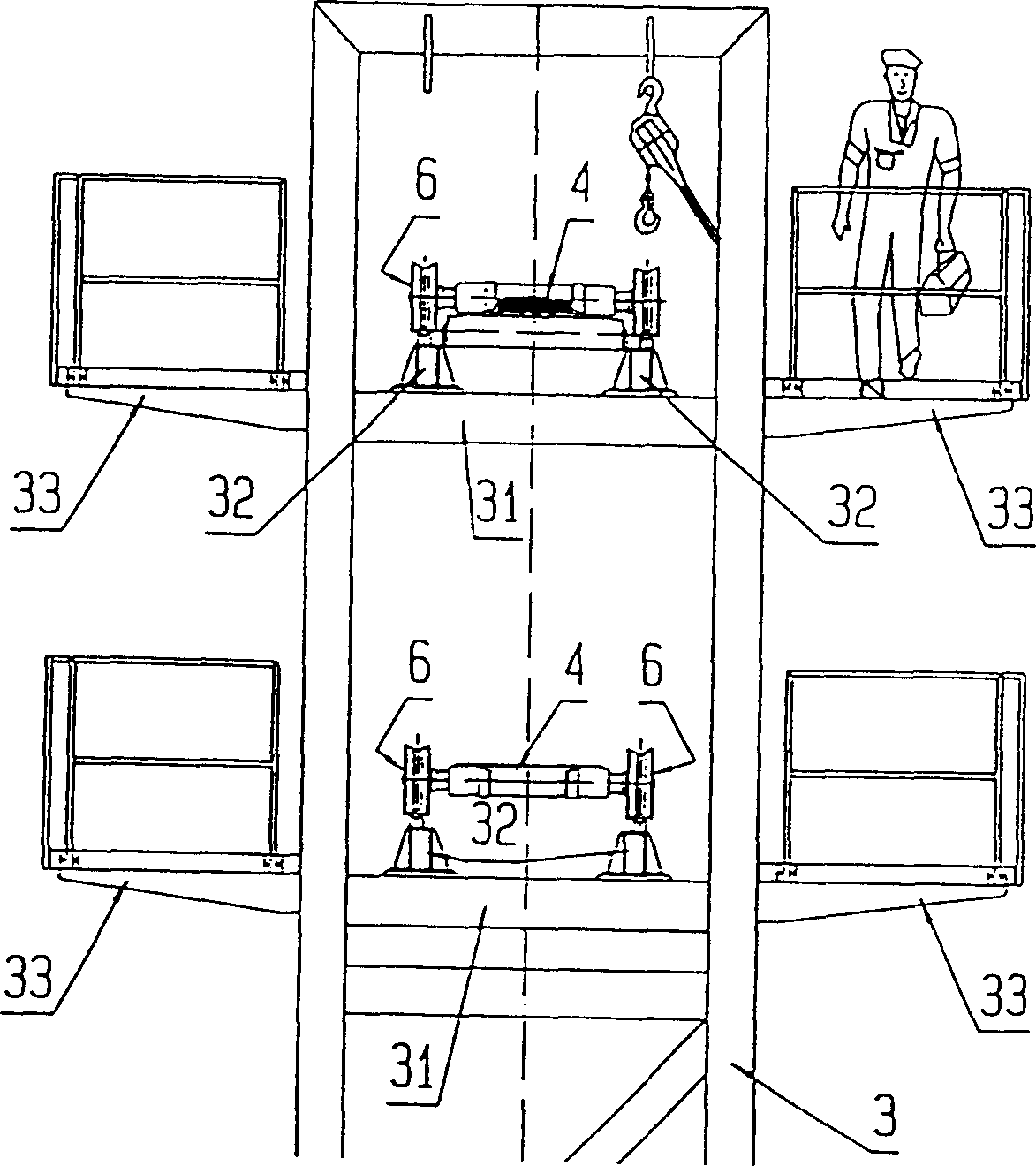

[0021] As shown in Fig. 1, the conveying system of the present invention has two pairs of conveying cables 1a, 1b and 2a, 2b located at different heights, which extend along the entire length of the conveying system and are formed in the same way as the conveying cables of the cable car system. The struts 3 support and are firmly fixed at the end of the conveyor system to the ground or to a foundation or the like.

[0022] Two pairs of conveyor cables 1 and 2 are associated with an endless conveyor belt 4 which is guided at both ends of the conveyor system around deflection rollers 71, at least one of which is driven. The conveyor belt 4 is also provided with a tensioning device 72 . A feeding device 73 , whereby the items to be conveyed are placed on the conveyor belt 4 , is provided at the beginning of the conveying system.

[0023] On both sides of the conveyor belt 4 there are rollers 6 which run into and out of the conveyor cables 1a, 1b and 2a, 2b at the ends of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com