Full-thickness asphalt pavement structure with steel wire mesh reinforced asphalt concrete as base layer

A technology of asphalt concrete and asphalt pavement, which is applied to cohesive pavement paved on site, roads, roads, etc., and can solve the problem of durability (high requirements for fatigue resistance, increased difficulty of financing for investment departments, increased total thickness of pavement structure, etc.) problems, to achieve long service life, simple structure, and improve the structural strength of the pavement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

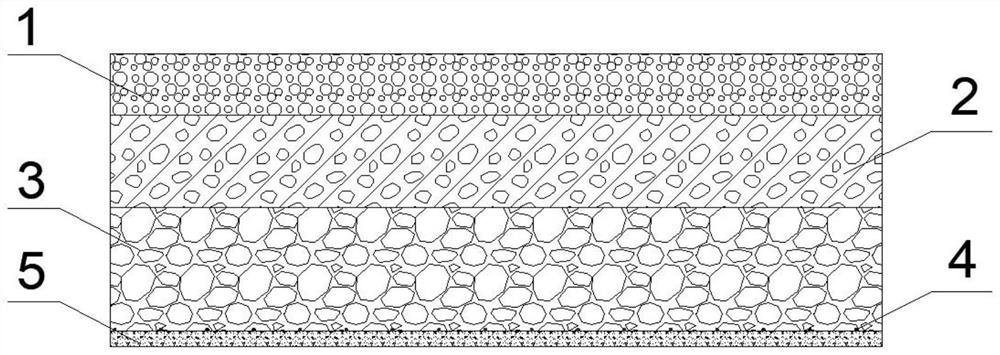

[0043] A full-thickness asphalt pavement structure with steel mesh reinforced asphalt concrete as the base layer of the present embodiment, such as figure 1 As shown, the pavement structure from top to bottom is:

[0044] The asphalt concrete surface layer 1 with high rutting resistance is AC-13, and its thickness is 6cm;

[0045] The high modulus asphalt concrete connecting layer 2 is AC-20, and its thickness is 12cm;

[0046] The high modulus asphalt concrete base 3 is ATB-25, and its thickness is 22cm;

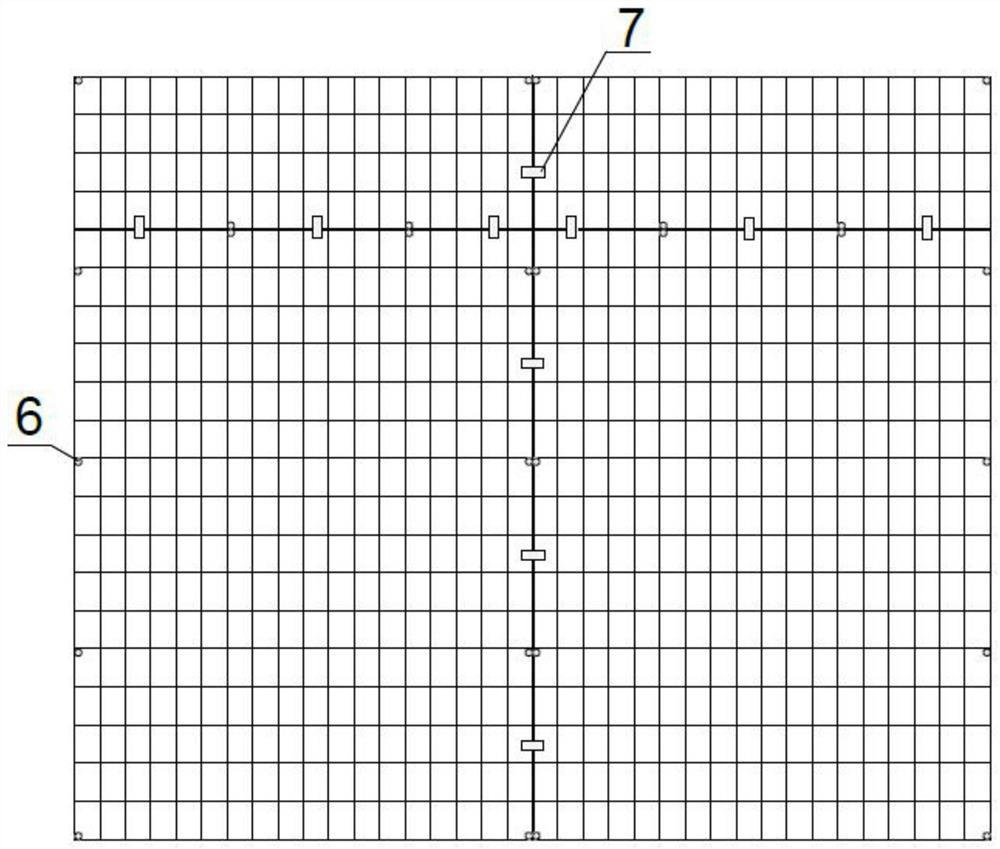

[0047] Steel mesh 4, its diameter is 2.0mm, the longitudinal and transverse distances are 4.0cm and 5.0cm respectively, and the elastic modulus is 210Gpa;

[0048] Slurry sealing layer 5, its thickness is 8mm;

[0049] The performance parameters of the pavement material are

[0050]

Embodiment 2

[0059] The finite element models of Examples 1, 2 and the comparative example were established respectively. In Example 2, on the basis of the pavement structure of Example 1, the thickness of the asphalt concrete of the connecting layer and the base layer was reduced, so that the bottom tensile strain of the asphalt layer of the pavement structure was SMX. It is close to the tensile strain SMX at the bottom of the asphalt layer in Comparative Example 1, so the thickness of the asphalt layer that can be reduced after adding steel mesh to the pavement is analyzed, and the final connection layer and base asphalt concrete are reduced by 6 cm and 10 cm, respectively. The parameters of the pavement material in Example 2 are the same as those in Example 1.

[0060] A kind of full-thickness asphalt pavement structure with steel mesh reinforced asphalt concrete as the base layer of the present embodiment, correspondingly, the pavement structure from top to bottom is:

[0061] AC-13 as...

Embodiment 3

[0071] The structure of the asphalt pavement in this embodiment is as follows from top to bottom:

[0072] The surface layer of asphalt concrete with high rutting resistance, its thickness is 3cm;

[0073] High modulus asphalt concrete connecting layer, its thickness is 10cm;

[0074] High modulus asphalt concrete base, its thickness is 15cm;

[0075] Wire mesh layer, its diameter is 1mm, the wire mesh size is 20mm×20mm, it can be rectangular or square, the wire is too thin and easy to roll;

[0076] Slurry seal, its thickness is 6mm;

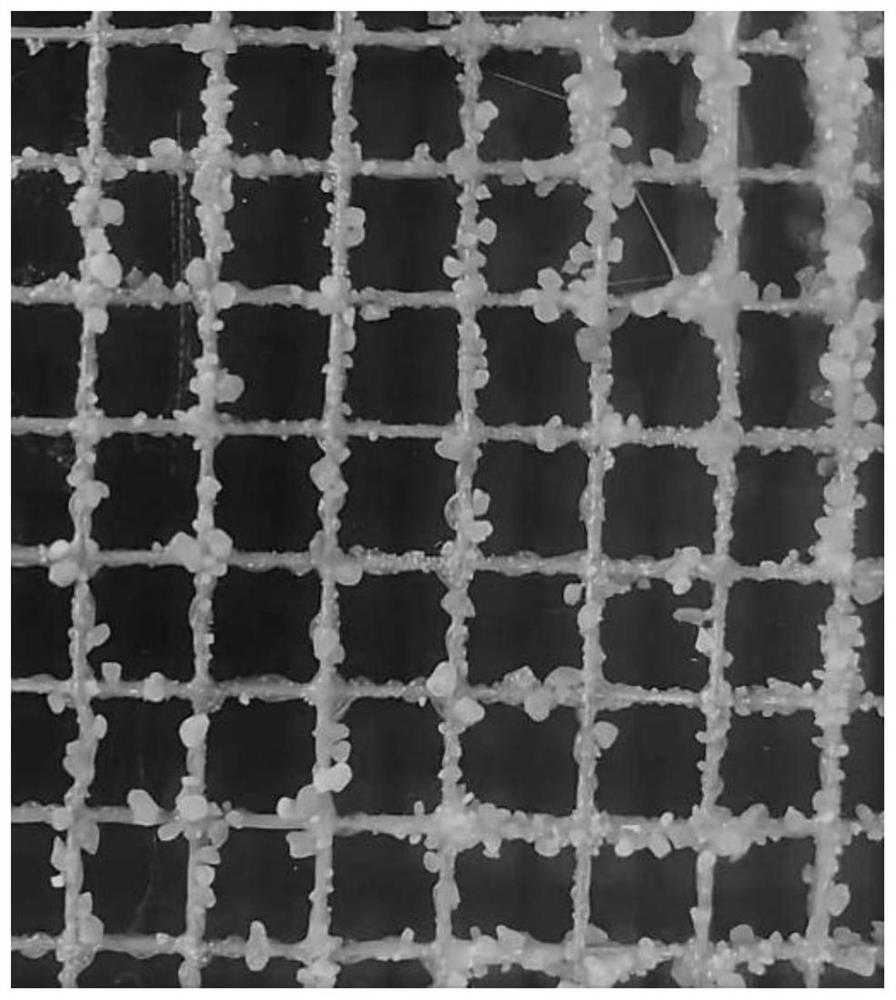

[0077] The above steel wire mesh is treated by epoxy resin coating, sanding unit and tackifying asphalt spraying unit. In the gap between the rollers, the surface of the steel mesh is covered with epoxy resin during the rotation of the roller, and epoxy resin is continuously added on the roller; using bisphenol A epoxy resin and heat-resistant curing agent, it has High bond strength and certain heat resistance.

[0078] The main structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com