Plate-like member vibration control device

A vibration damping device and component technology, applied in the direction of shock absorbers, spring/shock absorber design features, spring/shock absorber functional characteristics, etc., can solve problems such as noise and vibration amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

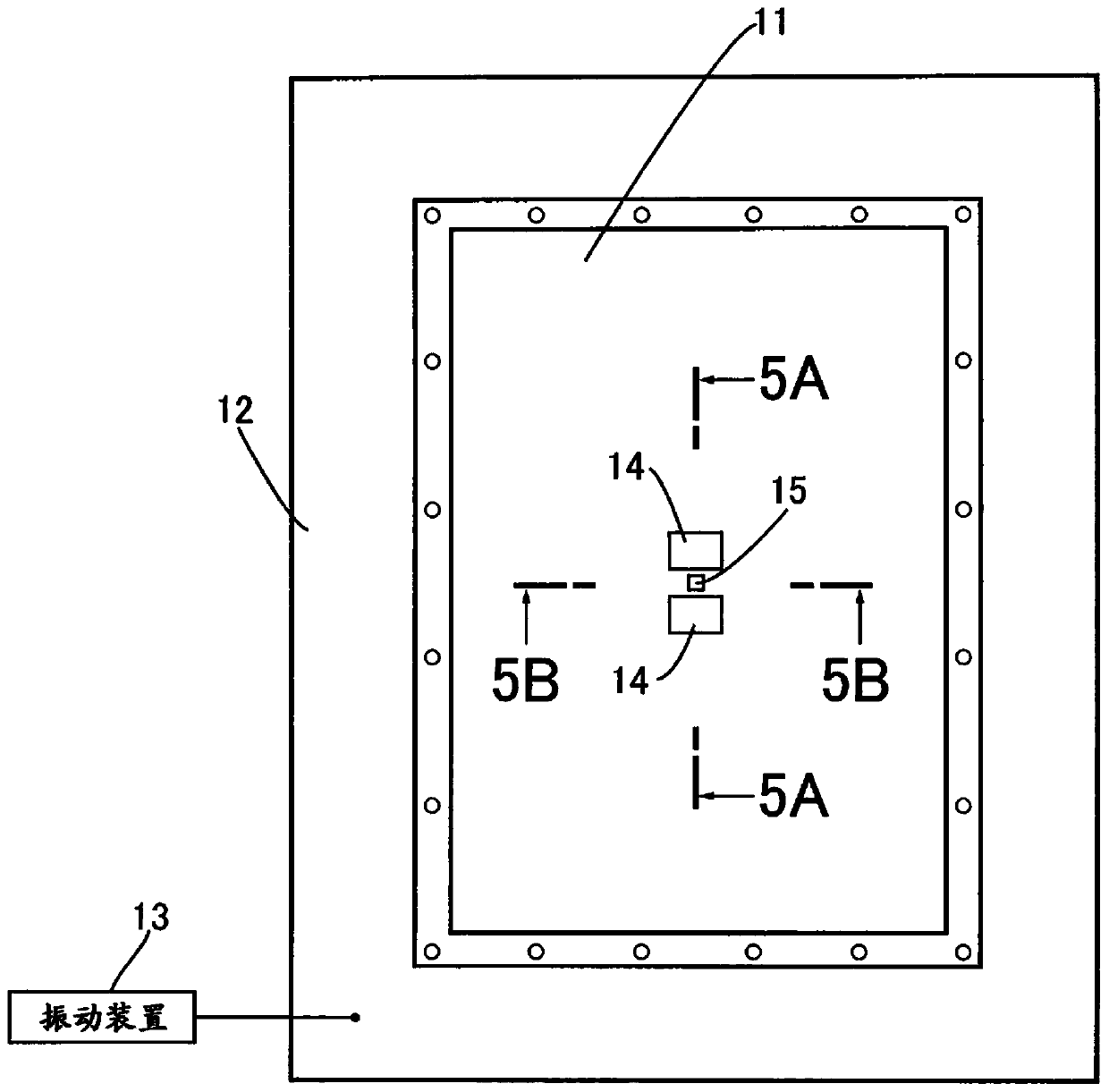

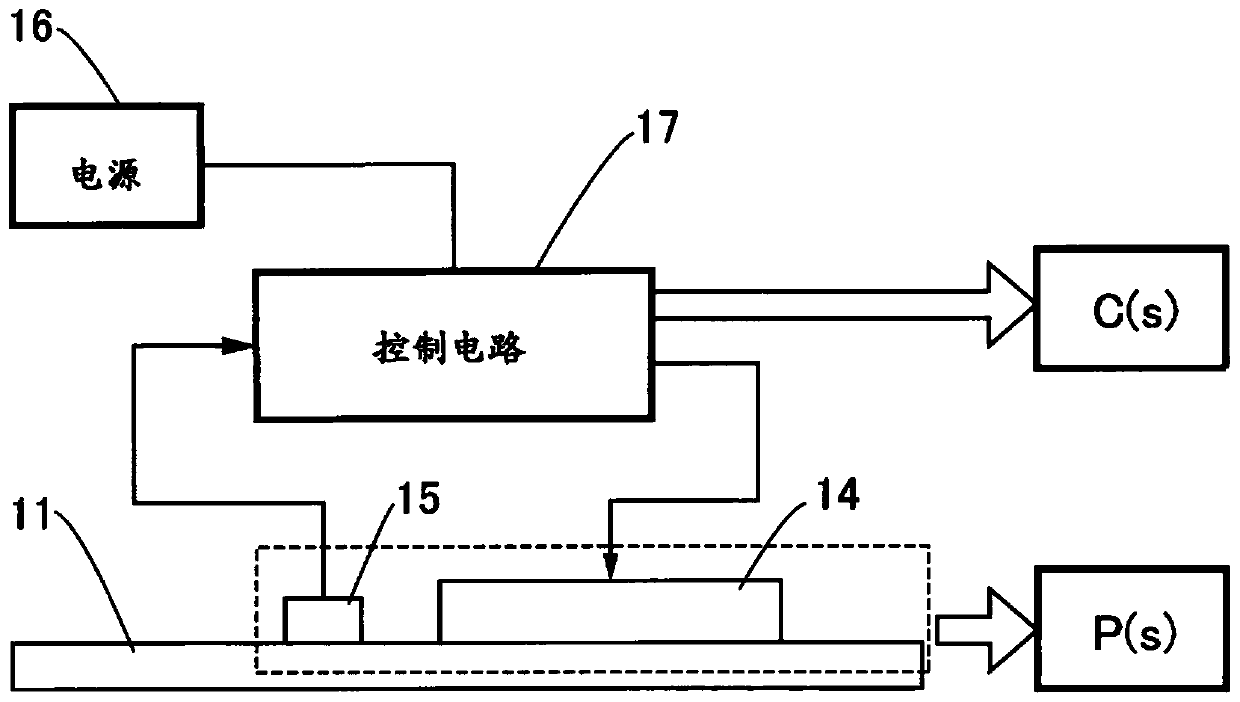

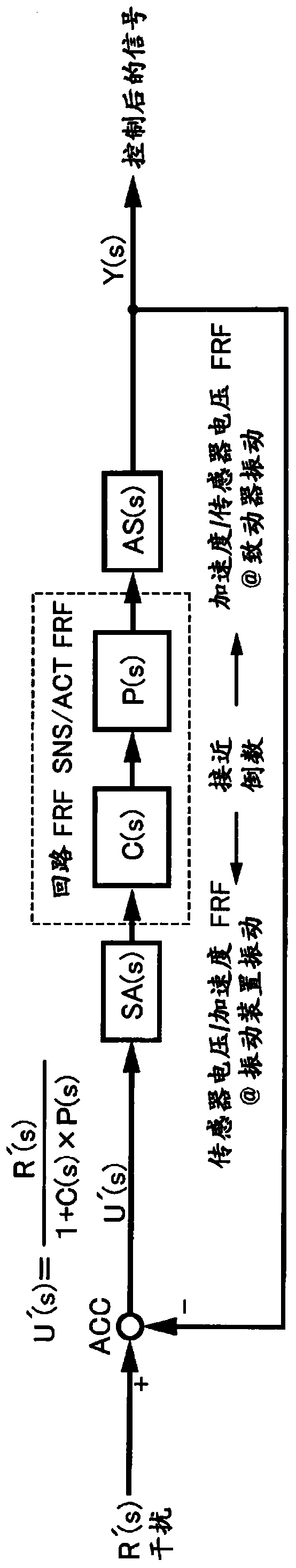

[0035] Below, based on Figure 1 to Figure 7 The first embodiment of the present invention will be described.

[0036] Such as figure 1 as well as figure 2 As shown, the plate-shaped member 11 to which the vibration damping device of the present invention is applied is composed of a rectangular plate made of carbon fiber reinforced resin, and the metal frame 12 supports the outer periphery of the plate-shaped member through a sufficiently lower elastic material. The metal frame 12 is connected to a vibrating device 13 to vibrate at various frequencies. The damping device for damping the vibration of the plate member 11 vibrated by the vibrating device 13 has: two piezoelectric element actuators 14 in the shape of a rectangular plate; a piezoelectric element sensor 15 in the shape of a rectangular plate; a power source 16; and The control circuit 17 controls the operation of the piezoelectric element actuator 14 based on the output of the piezoelectric element sensor 15 . ...

no. 2 Embodiment approach

[0061] Next, based on Figure 8 A second embodiment of the present invention will be described.

[0062] The vibration damping device of the first embodiment has two piezoelectric element actuators 14 and one piezoelectric element sensor 15, but the vibration damping device of the second embodiment has four piezoelectric element actuators 14 and four piezoelectric element Element sensor 15. At positions sandwiched by four piezoelectric element actuators 14 each formed in a rectangular shape, four piezoelectric element sensors 15 each formed in a strip shape are arranged in a cross shape. In series, in parallel, or in series combination (for example, after connecting two in parallel, connect the remaining two in series.) Electrically connect. In addition, the lengths of the four piezoelectric element sensors 15 are set so that anti-resonance can occur in the output voltage of the four piezoelectric element sensors 15 as a whole in the frequency range of 100 Hz or less.

[00...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap