Optical axis included angle measurement adjusting device

A technology for adjusting devices and measuring devices, which can be applied to measuring devices, optical devices, televisions, etc., and can solve problems such as inconvenience and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

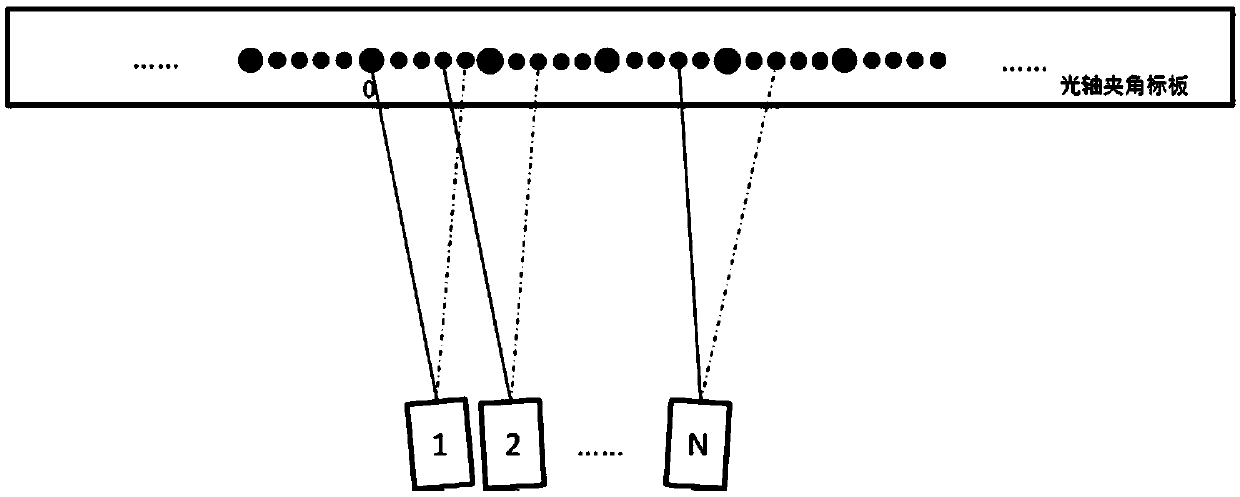

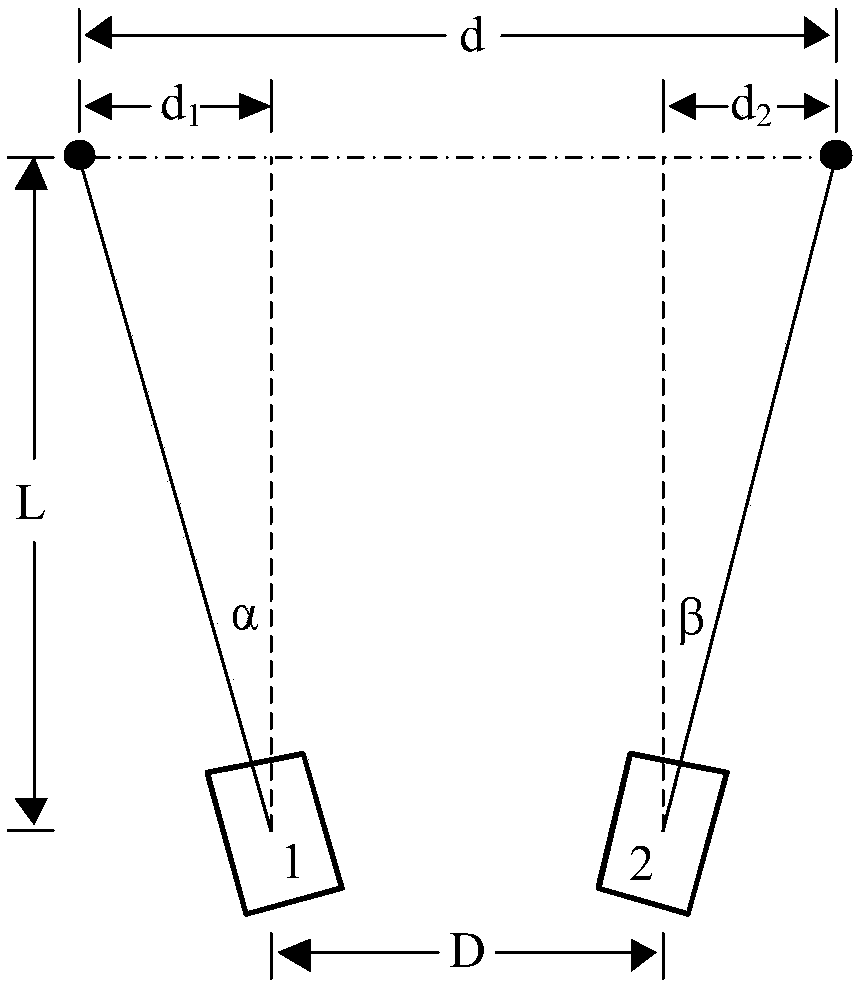

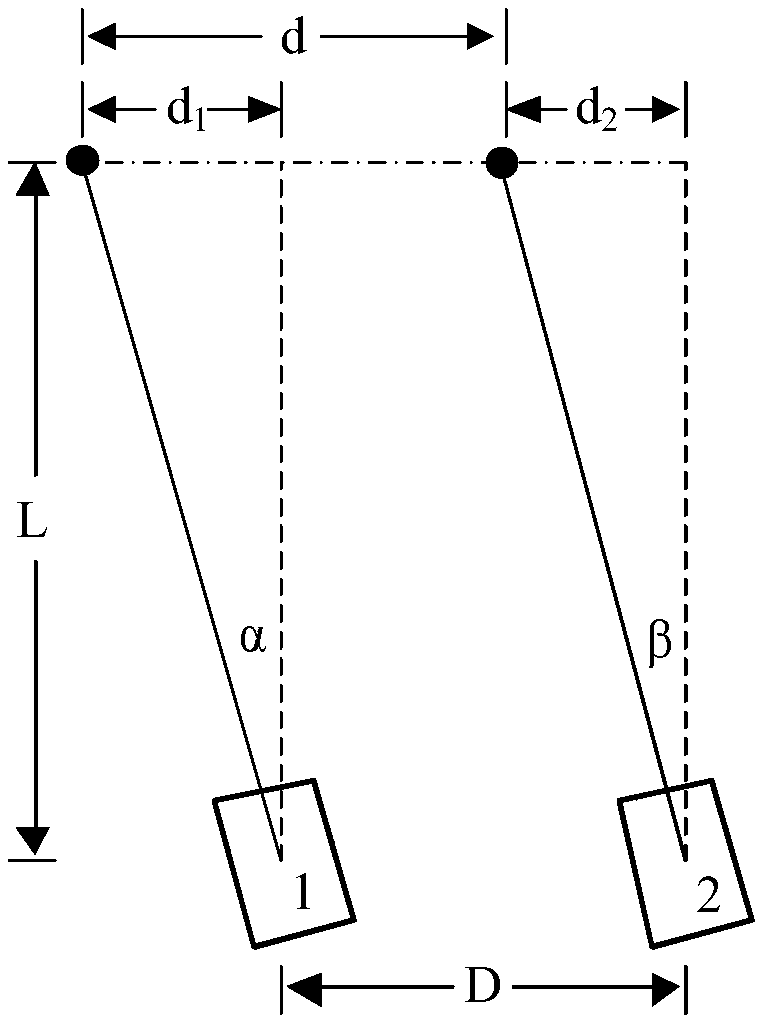

[0022] figure 1 It is an embodiment of the optical axis angle measurement and adjustment device of the present invention. Such as figure 1 As shown, what is proposed is a camera optical axis angle measurement device placed in the horizontal direction, and the positional relationship between the cameras is a left-right relationship. It includes cameras No. 1, No. 2...N installed with the optical axis angle to be measured and the optical axis angle measurement target plate. Cameras No. 1, No. 2...N are installed or assembled on the same height plane. The optical axis of the camera whose optical axis angle is to be measured faces the measurement target plate, and the measurement target plate is taken as the shooting target. The mounting bases of cameras 1 to N each have a mechanical structure for fine-tuning the angle, such as a universal joint, for calibration of the included angle of the optical axis. Camera real-time video can be electronically zoomed in. The distance bet...

Embodiment 2

[0066] Figure 4 It is another embodiment of the optical axis angle measurement and adjustment device of the present invention. This embodiment and figure 1 The difference is that the positional relationship of the camera group is an up-down relationship, and the optical axis angle measurement target is placed vertically. The optical axis angle measurement and adjustment process are the same as figure 1 Example.

[0067] Such as Figure 4 As shown, the optical axis angle measurement and adjustment device includes a camera for measuring the optical axis angle and a measurement target plate. Cameras No. 1, No. 2...N are placed vertically, and the positional relationship between the cameras is the online relationship. The optical axis angle measurement target plate is placed horizontally. Cameras No. 1, No. 2...N are installed or assembled on the same height plane. The optical axis of the camera whose optical axis angle is to be measured faces the measurement target plate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com