High-strength galvanized steel sheet and method for manufacturing same

A technology of galvanized steel sheet and manufacturing method, which is applied in the direction of manufacturing tools, hot-dip coating process, furnace, etc., and can solve the problems of difficult residual hydrogen and hydrogen embrittlement of blanks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

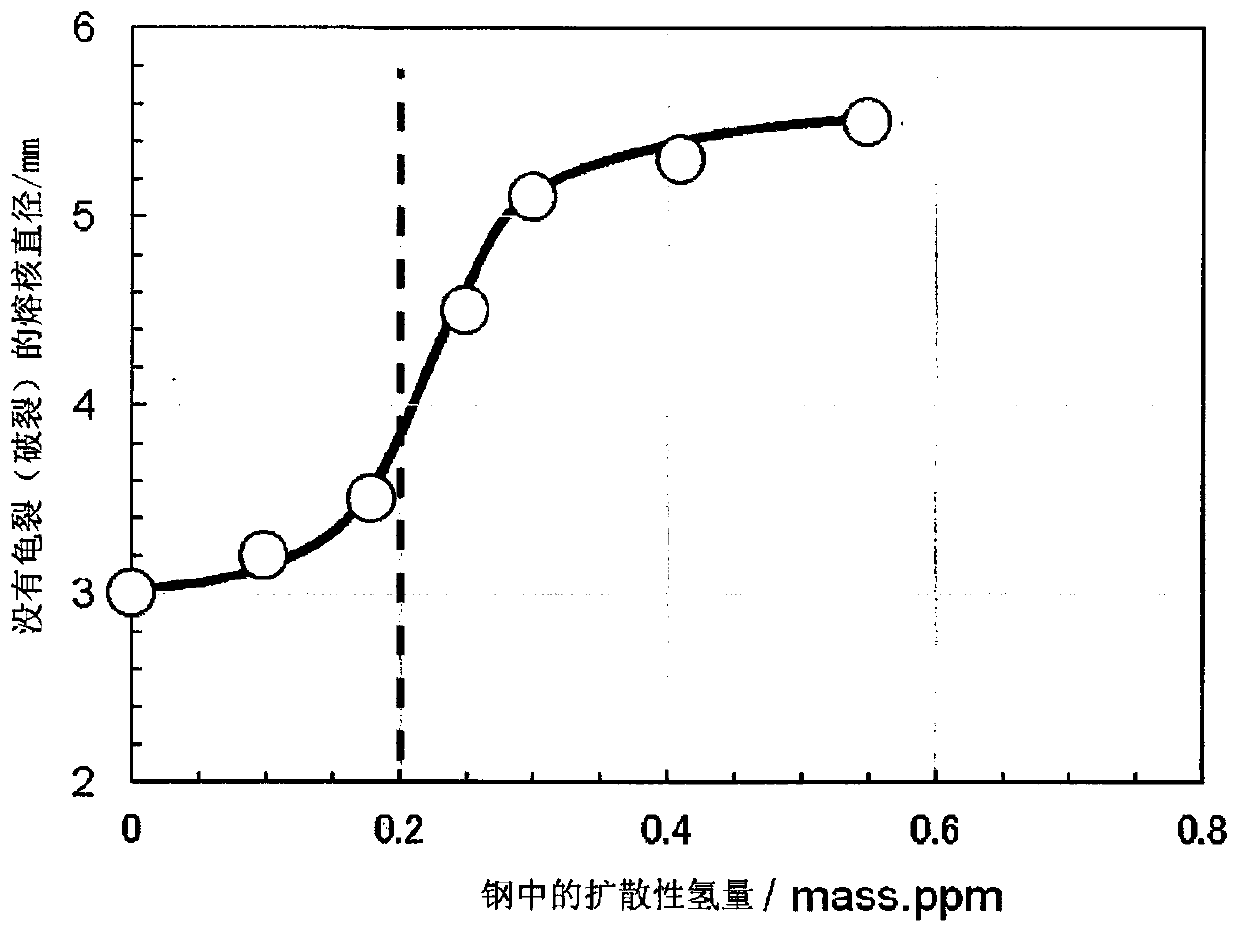

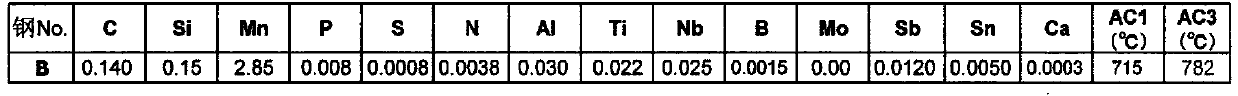

[0121] Molten steels having the compositions shown in Table 1 were melted in a converter and cast into slabs using a continuous casting machine. This slab was heated at 1200°C, and was produced into a hot-rolled coil at a finish rolling temperature of 840°C and a coil coiling temperature of 560°C. The hot-rolled coil was turned into a cold-rolled billet having a plate thickness of 1.4 mm at a cold reduction ratio of 50%. The cold-rolled billet is heated to 810°C (in the range of (Ac3 point-20°C) to 900°C) through annealing treatment with a hydrogen concentration of 9 vol.% and an annealing furnace atmosphere with a dew point of -30°C, stays for 15 seconds, and then cools To 500°C, stay for 30 seconds. Thereafter, galvanizing is carried out, alloying treatment is carried out, and after plating, it is cooled to below 100°C in a water tank with a water temperature of 40°C, and a high-strength alloyed galvanized steel sheet (product sheet) is produced at an average cooling rate o...

Embodiment 2

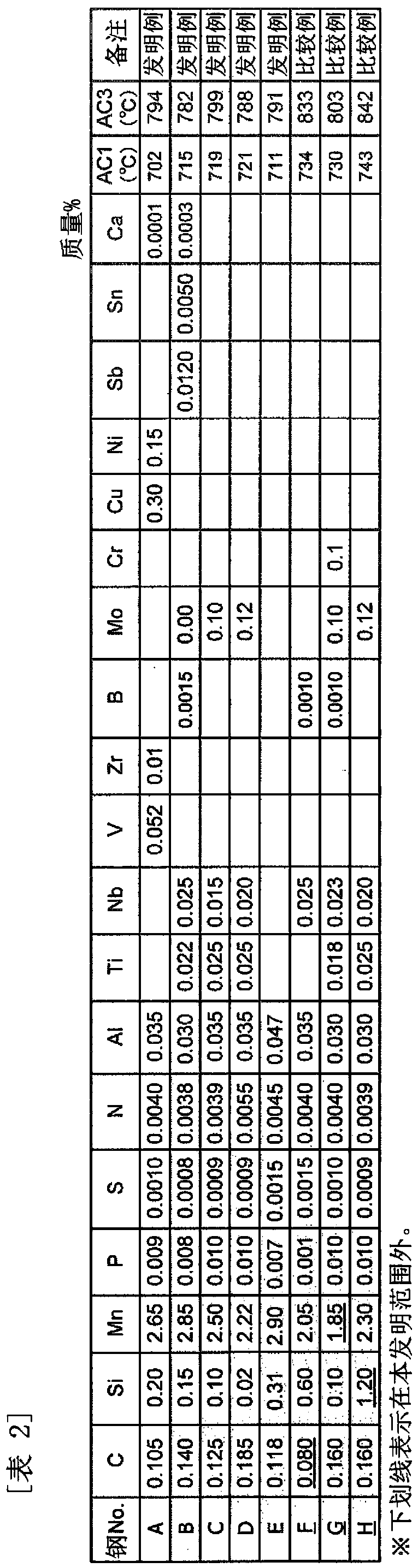

[0134] The molten steel with the composition shown in Table 2 was smelted in a converter, and after being made into a slab with a continuous casting machine, it was hot-rolled, cold-rolled, heated (annealed), pickled (Table 3) under various conditions shown in Table 3. In the case of "○" in 3, the HCl concentration of the pickling solution is adjusted to 5mass%, and the solution temperature is adjusted to 60°C for use), heat treatment and plating treatment, temper rolling, coil width trimming, post-heat treatment, Manufacture 1.4mm thick high-strength galvanized steel sheet (product sheet).

[0135] In addition, cooling (cooling after a plating process) was cooled to 50 degreeC or less with the water tank of 40 degreeC of water temperature.

[0136]

[0137] Take the sample of galvanized steel sheet obtained above, carry out structure observation and tensile test measurement according to the following methods, and calculate the fraction (area ratio) of metal structure, yiel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap