Manipulator for underwater operation

A technology of underwater operation and manipulator, applied in the field of manipulator, can solve the problems of high density of salt water, high water pressure, small contact area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

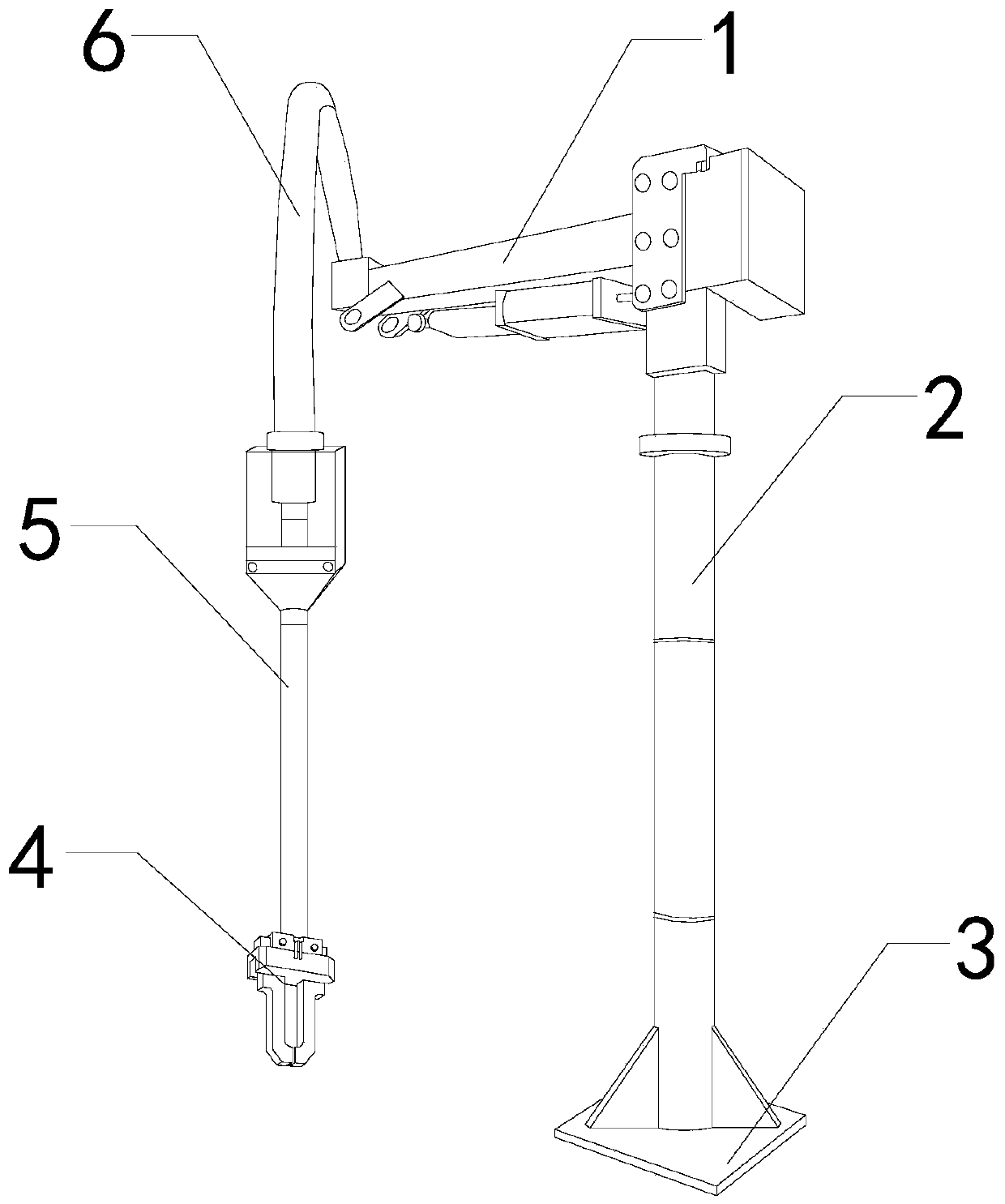

[0028] For example figure 1 -example Figure 5 Shown:

[0029] The invention provides a manipulator for underwater operation, its structure includes a steering rod 1, a support rod 2, a base 3, a gripper 4, a telescopic rod 5, and a connecting rod 6, and the steering rod 1 is movably engaged with the support rod 2 The upper end position of the support rod 2 is welded with the base 3, one end of the connecting rod 6 is connected with the telescopic rod 5, and the other end of the connecting rod 6 is embedded in the left end position of the steering rod 1, and the clamping The device 4 is installed at the bottom position of the telescopic rod 5.

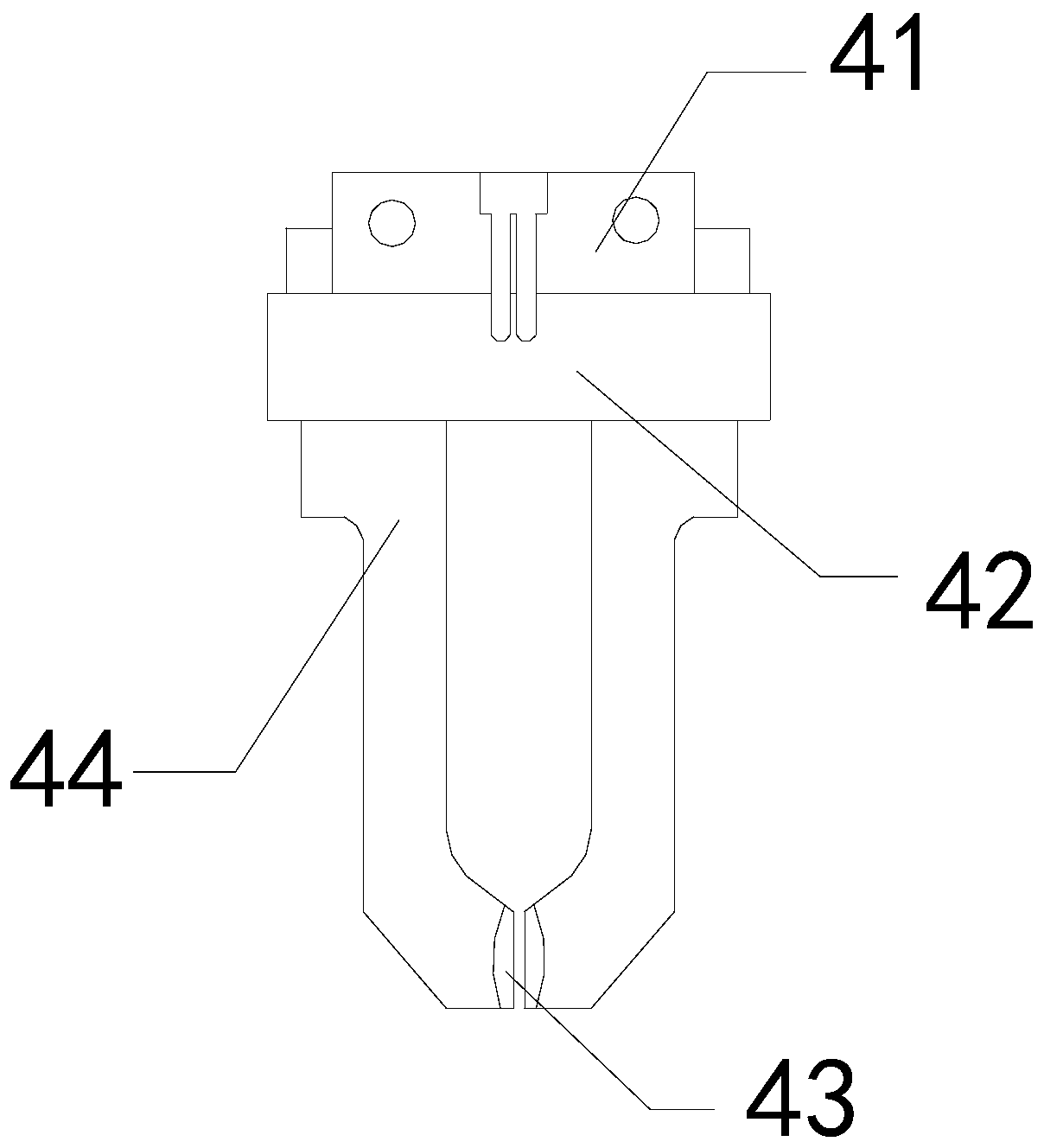

[0030] Wherein, the clamper 4 includes a connection base 41, a guide rail 42, a fixing mechanism 43, and a clamping block 44, the connection base 41 is embedded in the upper end of the guide rail 42, and the fixing mechanism 43 and the clamping block 44 are Integrated structure, the clamping block 44 is movably engaged with the lowe...

Embodiment 2

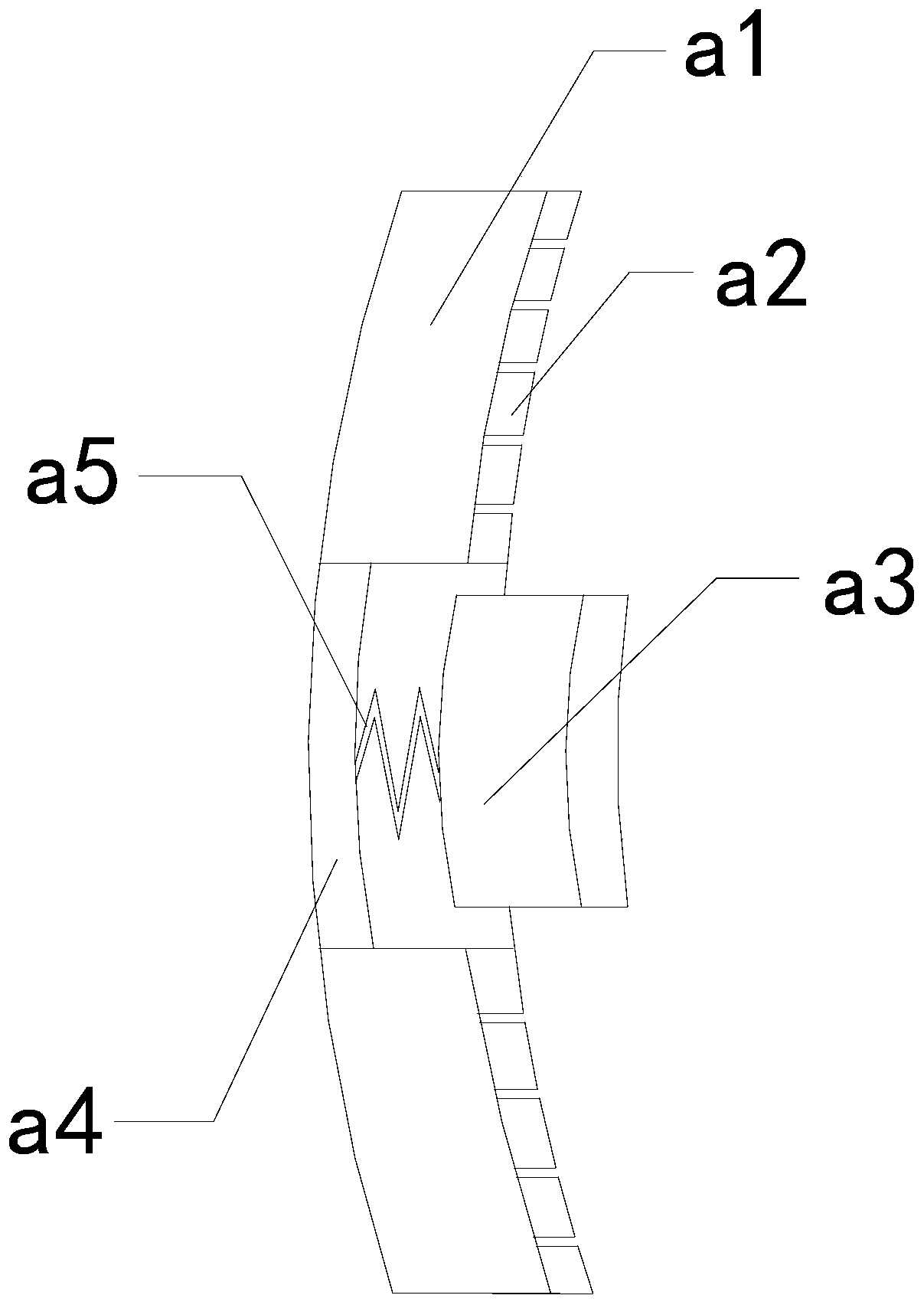

[0037] For example Image 6 -example Figure 9 Shown:

[0038] Wherein, the bottom block a23 includes a drainage mechanism b1 and a disc body b2, the drainage mechanism b1 and the disc body b2 are an integrated structure, and the drainage mechanism b1 has a circular structure, which can The moisture inside the disc body b2 is discharged.

[0039] Wherein, the drainage mechanism b1 includes an opening and closing piece b11, a frame body b12, a receiving block b13, and a direction limiting mechanism b14. The opening and closing piece b11 is movably engaged with the receiving block b13, and the receiving block b13 and the frame body b12 are Integrated structure, the direction limiting mechanism b14 is embedded and connected with the opening and closing piece b11, and the moisture inside the object generates an upward thrust on the opening and closing piece b11, so that the opening and closing piece b11 can be opened, so that the moisture inside the mechanism can be discharged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com