Fabrication method of fence-type titanium-based pbo2 anode for electrowinning of non-ferrous metals

A non-ferrous metal and manufacturing method technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of low current efficiency, uneven deposition layer, short life, etc., to improve current efficiency, simple manufacturing method, and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

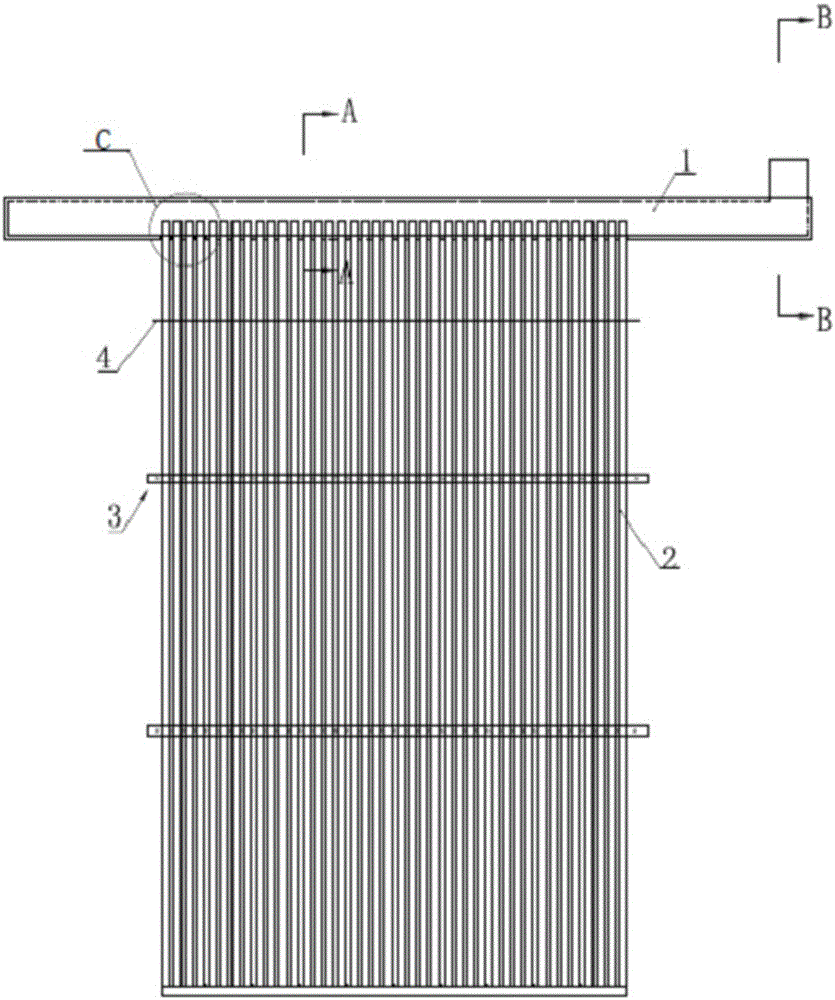

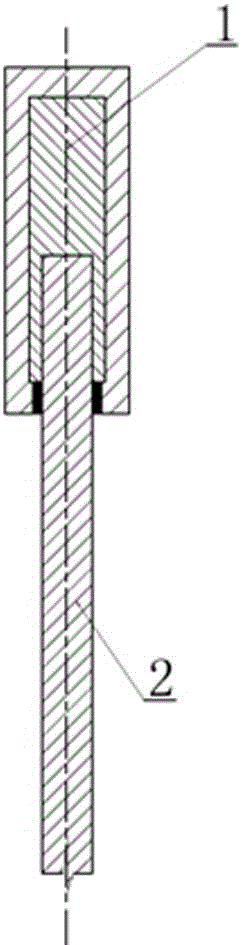

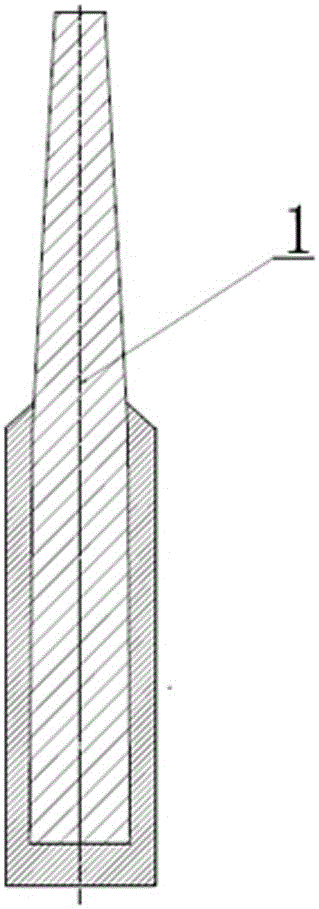

[0036] A cylindrical titanium rod with a diameter of 3 to 5 mm is drawn into a surface with such Figure 6 The titanium base of the zigzag pattern is shown, the tooth depth of the zigzag pattern is 0.3mm, and the tooth spacing is 0.4mm. A group of round holes are drilled side by side at the bottom of the titanium-clad copper conductive bar 1, and then a group of titanium substrates are inserted into the holes and welded to the titanium-clad copper conductive bar to form a fence structure with a size of 976mm×620mm. The titanium base part of the fence structure is degreased, sandblasted, oxide film removed, activated, and then alkaline electroplated with α-PbO 2 Composite layer and acid plating of β-PbO 2 Composite layer to obtain fence-type titanium-based PbO for non-ferrous metal electrowinning 2 anode. Specific steps are as follows:

[0037] (1) Put the entire group of titanium substrates connected under the titanium-clad copper conductive row into a 30% NaOH solution, h...

Embodiment 2

[0044] An elliptical titanium rod with a major axis of 5 mm and a minor axis of 3 mm is drawn into a surface with the following Figure 7 The titanium base of the zigzag pattern is shown, the tooth depth of the zigzag pattern is 0.1mm, and the tooth spacing is 0.1mm. A group of elliptical holes with a long axis of 5 mm are drilled side by side at the bottom of the titanium-copper-clad conductive bar 1, and then a group of titanium substrates are inserted into the holes, and welded with the titanium-clad copper conductive bar to form a fence structure with a size of 960mm×630mm. The titanium base part of the fence structure is degreased, sandblasted, oxide film removed, activated, and then alkaline electroplated with α-PbO 2 Composite layer and acid plating of β-PbO 2 Composite layer to obtain fence-type titanium-based PbO for non-ferrous metal electrowinning 2 anode. Specific steps are as follows:

[0045] (1) Put the entire group of titanium substrates connected under the...

Embodiment 3

[0052] A titanium rod with a diameter of 12 mm is drawn into a titanium substrate with a corrugated pattern on the surface. The corrugated teeth of the corrugated pattern have a depth of 0.9 mm and a pitch of 0.5 mm. Drill a group of Ф12mm round holes side by side at the bottom of the titanium copper-clad conductive bar 1, then insert a group of titanium substrates into the holes, and weld them with the titanium-clad copper conductive bar to form a fence structure with a size of 1080mm×640mm. The titanium base part of the fence structure is degreased, sandblasted, oxide film removed, activated, and then alkaline electroplated with α-PbO 2 Composite layer and acid plating of β-PbO 2 Composite layer to obtain fence-type titanium-based PbO for non-ferrous metal electrowinning 2anode. Specific steps are as follows:

[0053] (1) Put the whole group of titanium matrix connected to the bottom of the titanium-clad copper conductive bar into a 50% NaOH solution, heat and boil to rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com