Antibacterial acrylic plate and preparation method thereof

A technology of acrylic sheet and antibacterial agent, applied in the field of antibacterial acrylic sheet, can solve the problems of high price, low strength and toughness, poor toughness, etc., and achieve the effects of easy control, simple preparation method and improved weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

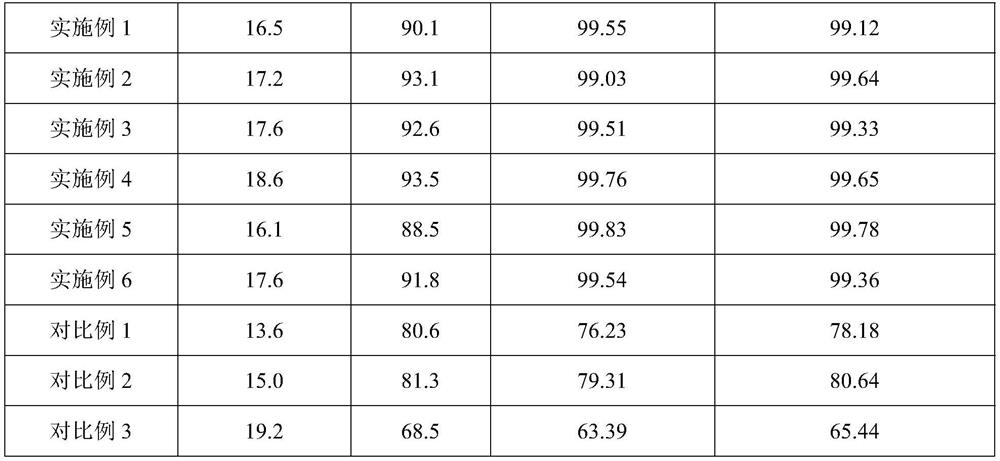

Examples

Embodiment 1

[0029] An antibacterial acrylic plate, comprising the following components by weight:

[0030] 60 parts of polymethyl methacrylate, 0.1 part of polyquaternium-1, 0.1 part of crosslinking agent TAC, 2 parts of 2,2,4,4-tetramethyl-1,3-cyclobutanediol.

[0031] The antibacterial acrylic plate comprises the following preparation steps:

[0032] S1: Stir polymethyl methacrylate, polyquaternium-1, crosslinking agent TAC, 2,2,4,4-tetramethyl-1,3-cyclobutanediol at room temperature to obtain the prepared mix;

[0033] S2: Put the premixed material into the semi-finished product extruder, extrude at 170°C, extrude and granulate to obtain pellets;

[0034] S3: Put the pellets into the finished product extruder, the extrusion temperature is 200°C, and the cross-linking is completed under the electron irradiation with a radiation dose of 200kGy to obtain an antibacterial acrylic sheet.

Embodiment 2

[0036] An antibacterial acrylic plate, comprising the following components by weight:

[0037] 70 parts of polymethyl methacrylate, 0.5 parts of polyquaternium-1, 0.5 parts of crosslinking agent TAC, 4 parts of 2,2,4,4-tetramethyl-1,3-cyclobutanediol.

[0038] The antibacterial acrylic plate comprises the following preparation steps:

[0039] S1: Stir polymethyl methacrylate, polyquaternium-1, crosslinking agent TAC, 2,2,4,4-tetramethyl-1,3-cyclobutanediol at room temperature to obtain the prepared mix;

[0040] S2: Put the premixed material into the semi-finished product extruder, extrude at 170°C, extrude and granulate to obtain pellets;

[0041] S3: Put the pellets into the finished product extruder, the extrusion temperature is 200°C, and the cross-linking is completed under the electron irradiation with a radiation dose of 200kGy to obtain an antibacterial acrylic sheet.

Embodiment 3

[0043] An antibacterial acrylic plate, comprising the following components by weight:

[0044] 80 parts of polymethyl methacrylate, 1 part of polyquaternium-1, 1 part of crosslinking agent TAC, 8 parts of 2,2,4,4-tetramethyl-1,3-cyclobutanediol.

[0045] The antibacterial acrylic plate comprises the following preparation steps:

[0046] S1: Stir polymethyl methacrylate, polyquaternium-1, crosslinking agent TAC, 2,2,4,4-tetramethyl-1,3-cyclobutanediol at room temperature to obtain the prepared mix;

[0047] S2: Put the premix into the semi-finished product extruder, extrude at 170°C, extrude and granulate to obtain pellets;

[0048] S3: Put the pellets into the finished product extruder, the extrusion temperature is 200°C, and the cross-linking is completed under the electron irradiation with a radiation dose of 200kGy to obtain an antibacterial acrylic sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com