Release film for MLCC and preparation method thereof

A release film, lamination technology, applied in coatings, polyurea/polyurethane coatings, epoxy coatings, etc., can solve the problems of curing deformation, deformation, affecting the quality of lamination capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

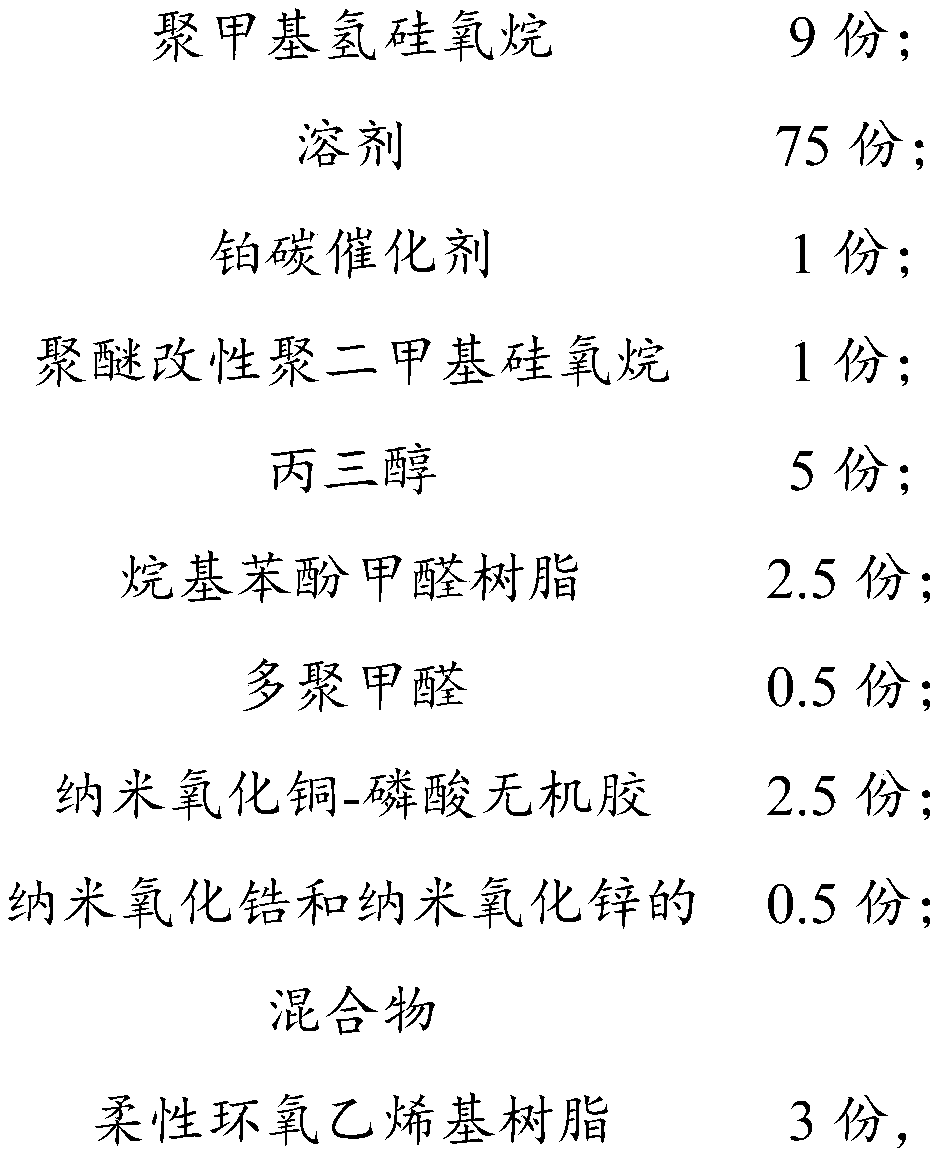

[0030] The release film for laminated capacitors, in parts by weight, its preparation raw materials include:

[0031]

[0032] Wherein, the solvent is selected from the mixture of methanol, ethylene glycol, n-heptane, butanone, and ethyl acetate, and the ratio of methanol, ethylene glycol, n-heptane, butanone, and ethyl acetate is 1:1 :3:3:1. The average particle size of the platinum-carbon catalyst is 40 μm, and the platinum content is 3%-6%. In the mixture of nano zirconia and nano zinc oxide, the particle size of the nano zirconia and nano zinc oxide particles is 100nm.

[0033] The method for preparing a release film using the raw materials of the above-mentioned components and content, the steps include:

[0034] (1) Add polymethylhydrosiloxane, methanol, ethylene glycol, n-heptane, butanone, and ethyl acetate into container A (such as a stainless steel bucket), and stir with a stirrer at a stirring speed of 700r / min. Stirring time is 3min;

[0035] (2) Then add po...

Embodiment 2

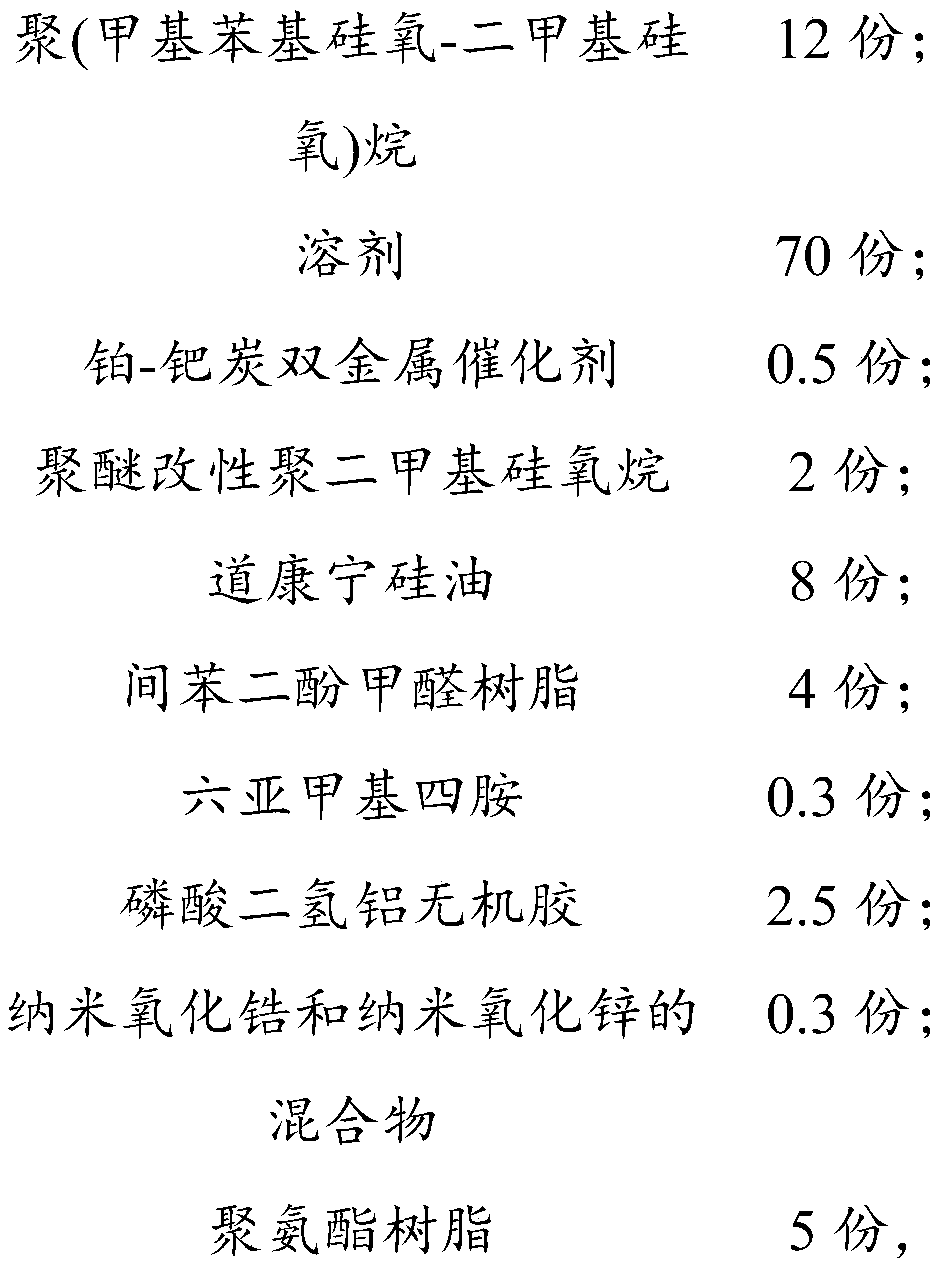

[0041] The release film for laminated capacitors, in parts by weight, its preparation raw materials include:

[0042]

[0043] Wherein, the solvent is selected from the mixture of methanol, ethylene glycol, n-heptane, butanone, and ethyl acetate, and the ratio of methanol, ethylene glycol, n-heptane, butanone, and ethyl acetate is 1:1 :2:4:1. The average particle size of the platinum-palladium carbon bimetallic catalyst is 60 μm, and the platinum content is 5%-12%. In the mixture of nano-zirconia and nano-zinc oxide, the particle size of the nano-zirconia and nano-zinc oxide particles is 150nm.

[0044]The preparation method of the release film for the laminate capacitor in this embodiment is the same as that in Embodiment 1, so no detailed description is given here.

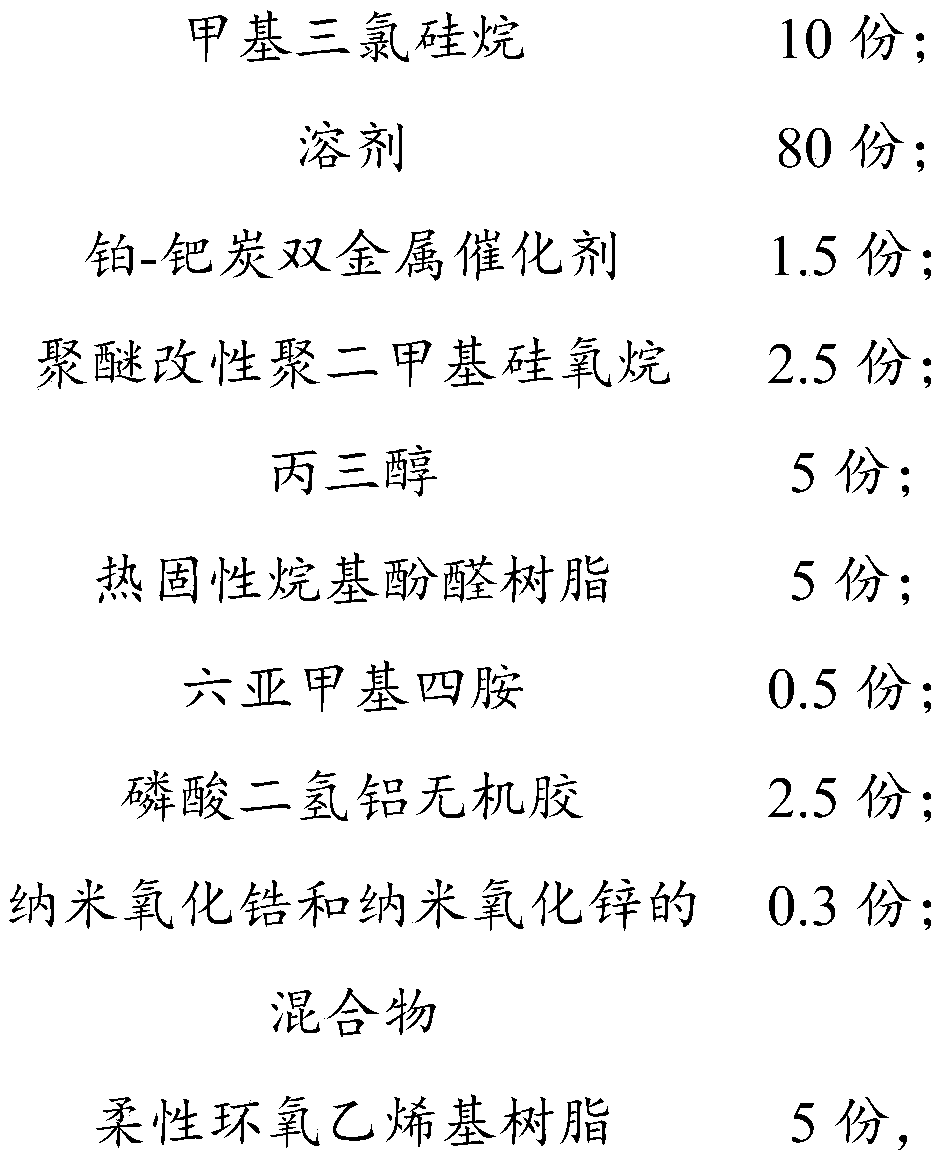

Embodiment 3

[0046] The preparation method of the release film for the laminated capacitor of this example is basically the same as that of Example 1, except that polyurethane resin is used as the spreading agent in Example 3, and flexible epoxy vinyl resin is used as the spreading agent in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap