Steel column mounting error adjusting device and method

A technology of installation error and adjustment device, applied in the direction of hoisting device, program control in sequence/logic controller, electrical program control, etc., can solve the problems of safety risk, low efficiency of hoisting operation, and no provision of steel column position adjustment measures. , to achieve high accuracy, high sensitivity, and reduce the risk of manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

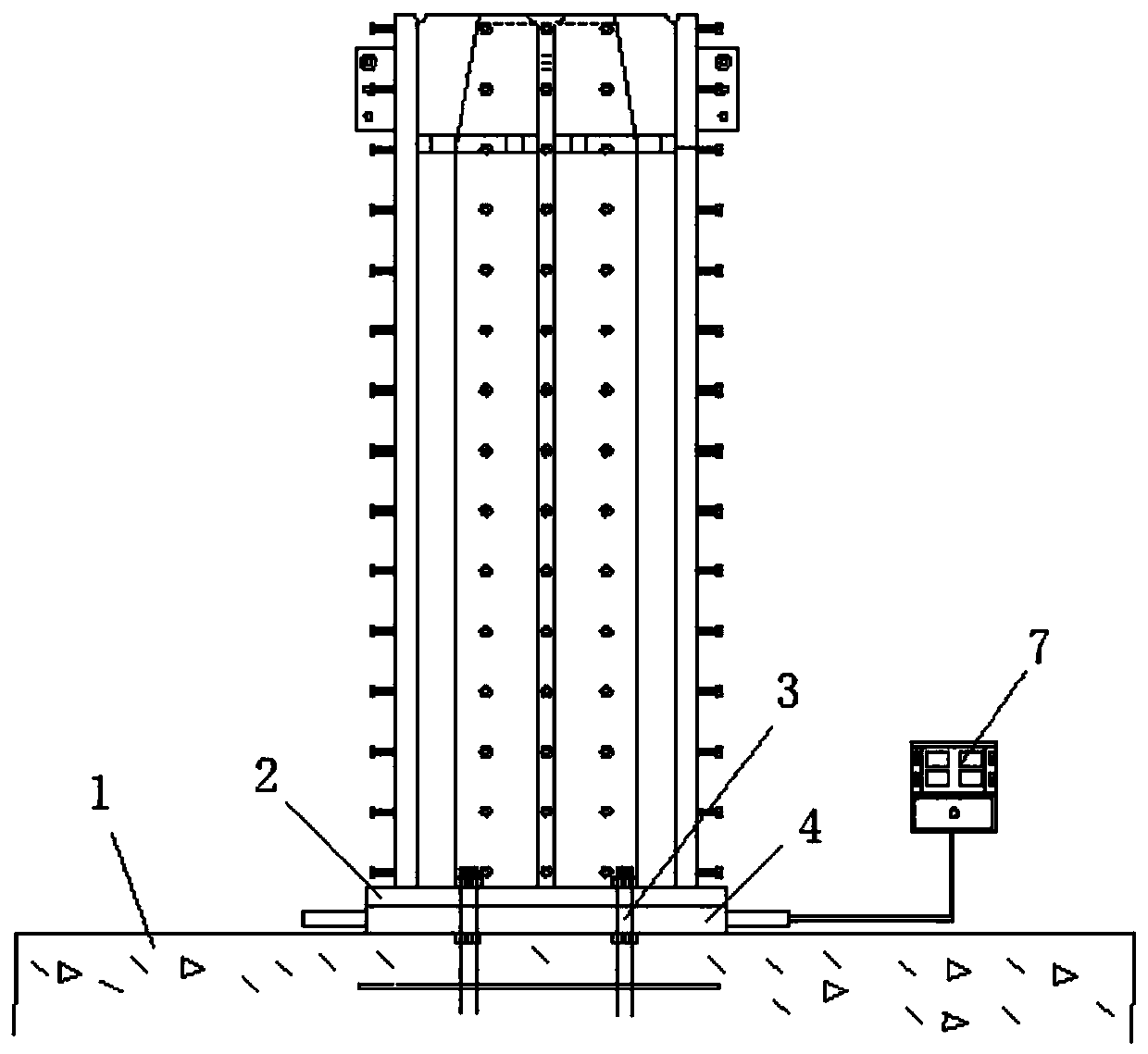

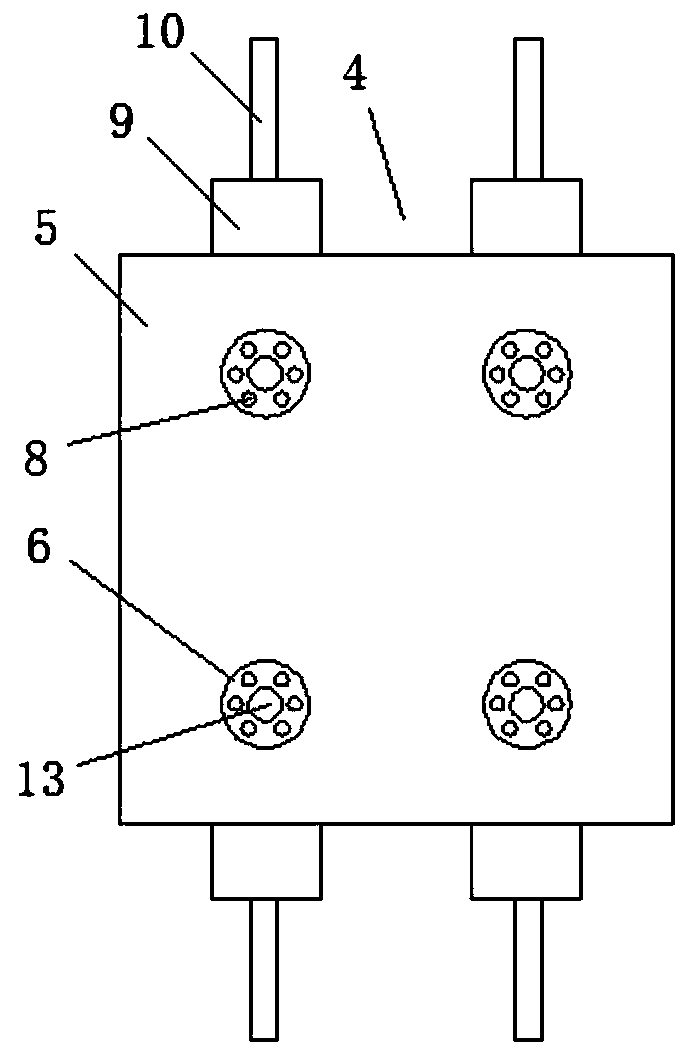

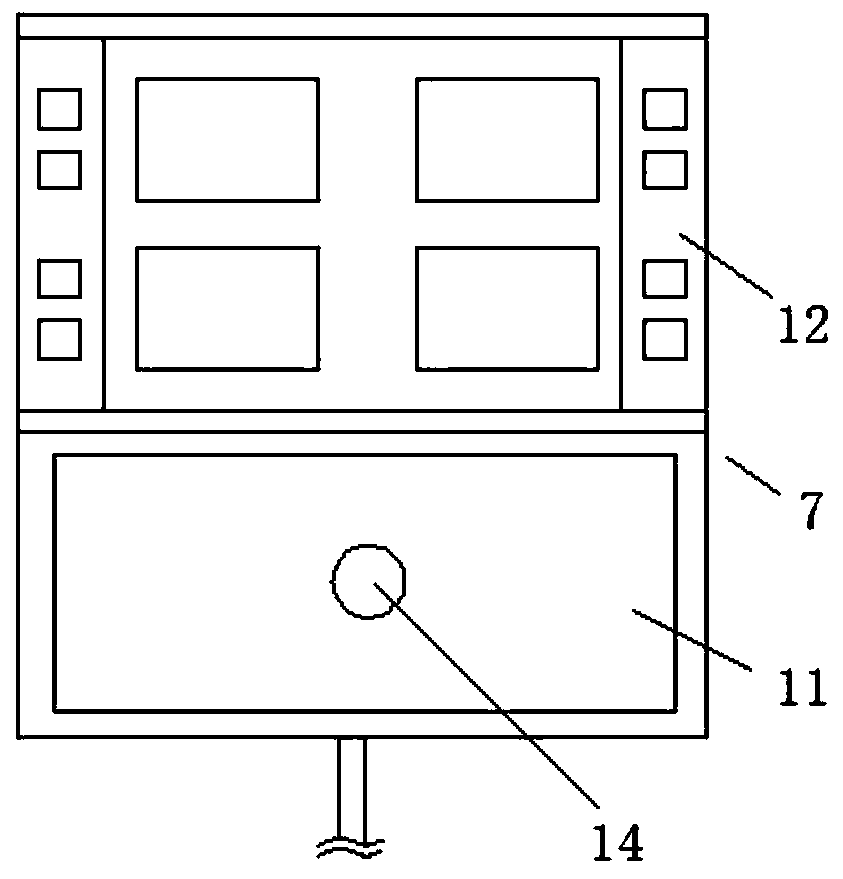

[0028] Such as Figure 1-2 As shown, a steel column installation error adjustment device is installed between the concrete foundation 1 and the steel column base 2, and includes an adjustment device 4 and a control device 7. The adjustment device 4 includes an adjustment device 5 and a plurality of liftable movable The top plate 6, the movable top plate 6 is arranged symmetrically on the upper surface of the adjusting device 5, and the positions corresponding to the adjusting device 5 and the moving top plate 6 are provided with bolt through holes 13; the control device 7 includes a pressure sensor 8 and integrated setting controller 11 and operation panel 12, a group of pressure sensors 8 are evenly arranged on the outer ring of the upper surface of the movable top plate 6, and the pressure sensors 8 are detachably electrically connected to the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com