Manufacture method of glass or ceramic product label

A technology of ceramic products and production methods, which is applied in the direction of coating, etc., can solve the problems that the applique process cannot be mechanized, automated production, cannot meet the requirements of completely consistent product appearance, and the color of high-temperature decal paper labels is not bright enough. The uniformity of product patterns, the reduction of manual operation risks, and the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

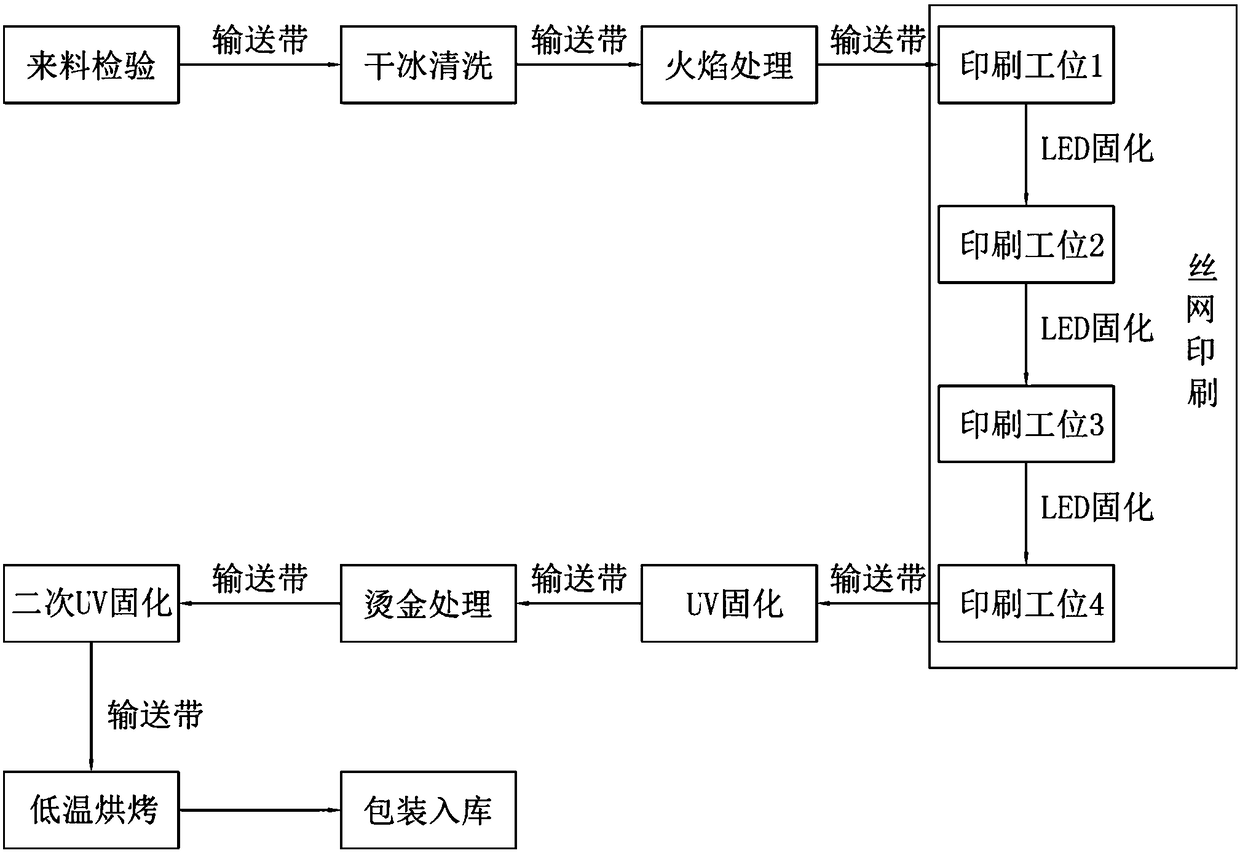

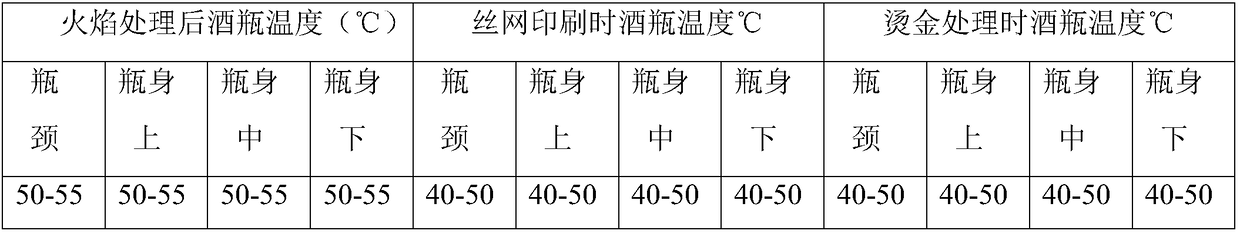

[0039] In this embodiment, the label production of glass wine bottles is taken as an example. It is carried out on an automated production line, and each link is transported by a conveyor belt. Low-temperature baking line, each equipment is connected with each other by a connecting line and a conveyor belt, and the transfer between different conveyor belts is realized manually or by a robot. Such as figure 1 As shown, a kind of manufacturing method of glass wine bottle label provided by the present embodiment comprises the following steps:

[0040] S0: Inspect the glass wine bottle to maintain the consistency and cleanliness of the shape of the glass or ceramic products, and ensure that there are no obvious appearance defects. The shape of the glass bottle must ensure a tolerance of ±1mm.

[0041] S1. Pretreat the glass wine bottle to remove oil and impurities on the surface of the substrate.

[0042] Step S1 includes the following sub-steps:

[0043] S11. The glass wine bo...

Embodiment 2

[0056] This example takes the label production of ceramic wine bottles as an example. It is carried out on an automated production line, and each link is transported by a conveyor belt. The conveyor belt is sequentially connected to a dry ice cleaning machine, a flame machine, a screen printing machine, a UV curing machine and a low-temperature baking line. . A kind of manufacturing method of ceramic wine bottle label provided by the present embodiment, comprises the following steps:

[0057] S0: Inspect ceramic wine bottles, maintain the consistency and cleanliness of ceramic or ceramic products, and ensure that there are no obvious appearance defects. The shape of glass bottles must ensure a tolerance of ±1mm.

[0058] S1. Pretreat the ceramic wine bottle to remove oil and impurities on the surface of the substrate.

[0059] Step S1 includes the following sub-steps:

[0060] S11, cleaning the ceramic wine bottle with dry ice by a dry ice cleaning machine;

[0061] S12. Pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com