Underwater robot laying device

An underwater robot and robot technology, applied in underwater operation equipment, transportation and packaging, ship parts, etc., can solve problems such as inability to make predictions in advance, high requirements for operators, and difficult implementation, and achieve simple structure , the method is flexible and changeable, and the effect of reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

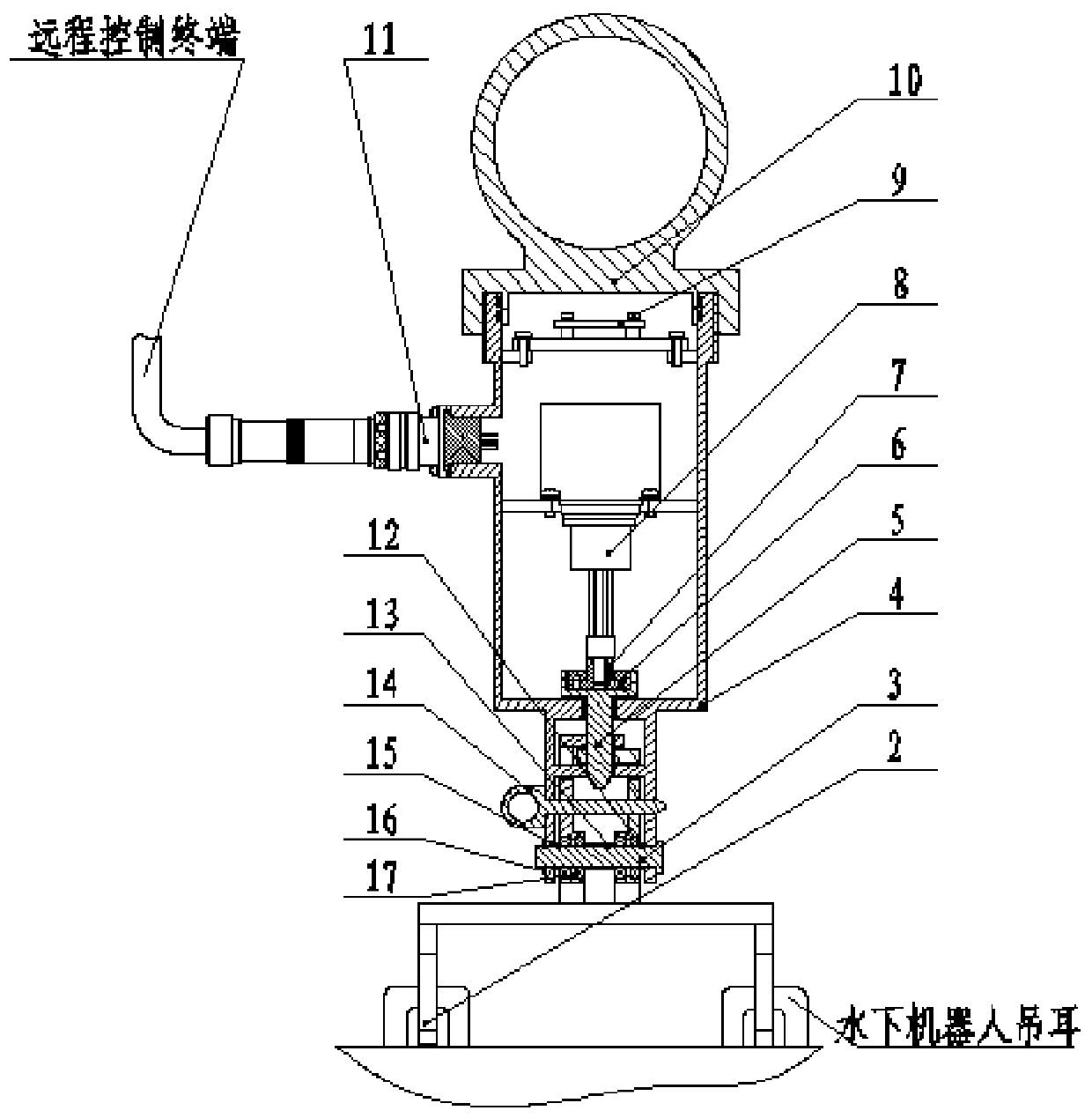

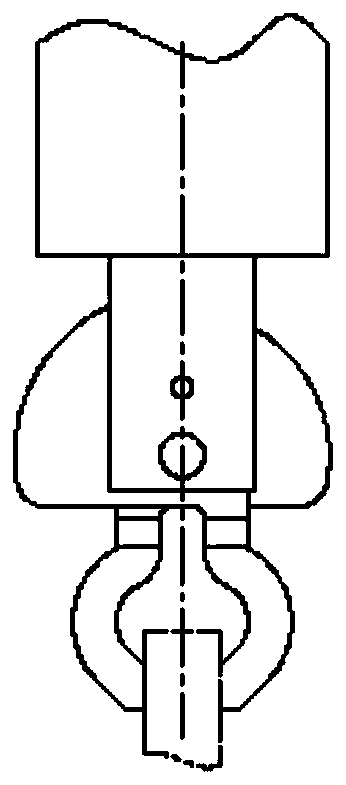

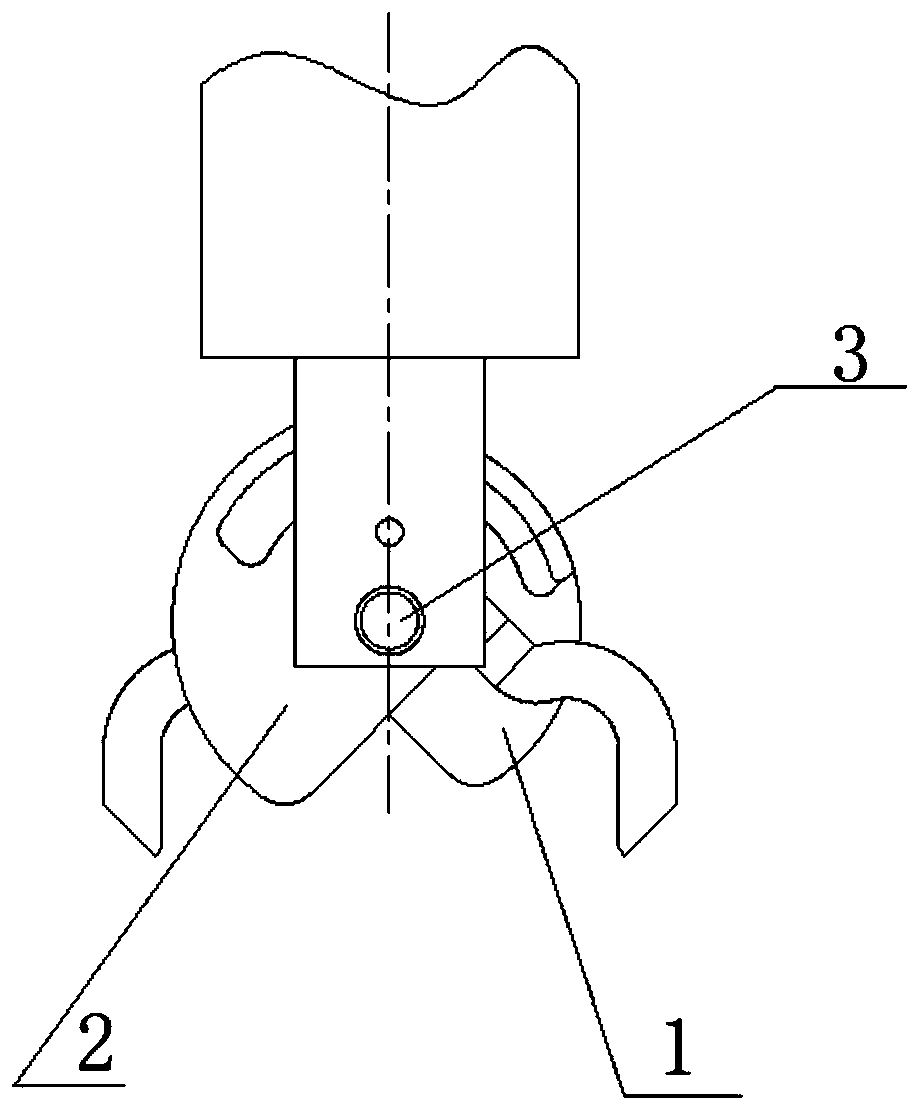

[0021] This embodiment provides an underwater robot deployment device, such as figure 1 As shown, it includes right clip hook 1, left clip hook 2, sealing cylinder, fixed shaft 3, release shaft 5, linear motor 8, motor control board 9, watertight connector 11, right snap ring 12, middle snap ring 13, left Snap ring 15, positioning snap ring 16, stainless steel bearing 17 and positioning pin 14.

[0022] The sealing cylinder includes a sealing cylinder 4 and a sealing end cover 10. The sealing cylinder 4 provides installation and sealing space for the linear motor 8 and the motor control board 9. The sealing cylinder 4 is designed with an installation interface for the linear motor 8 and the motor control board 9 , to ensure that the installation is firm and reliable. The sealing cylinder 4 is a cylinder with one end open, and the open end is threadedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com