Freight vehicle weighbridge monitoring method capable of preventing weighing cheating

A technology for weighbridges and vehicles, which is applied in the field of weighing scales that use non-contact physical detection means to monitor and eliminate abnormal weighing. It can solve problems such as incomplete consideration of the weighbridge measurement system, inaccurate measurement values, and low efficiency. Maintenance, simplification of device composition, and reduction of economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

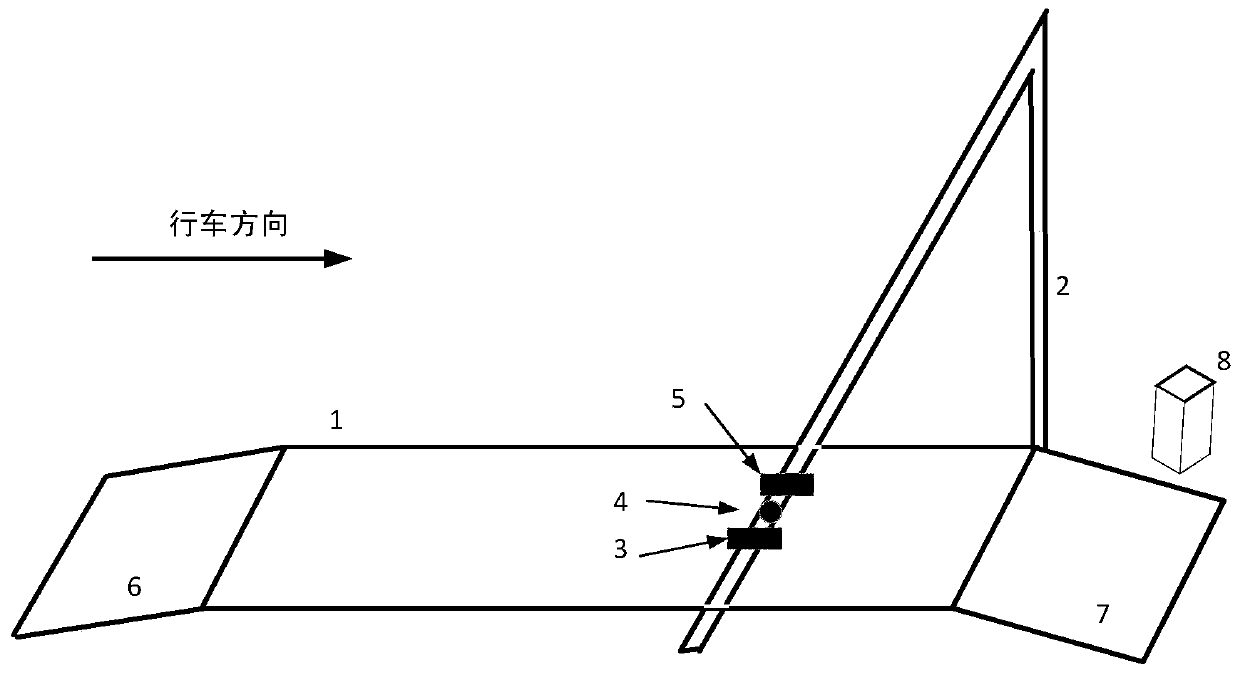

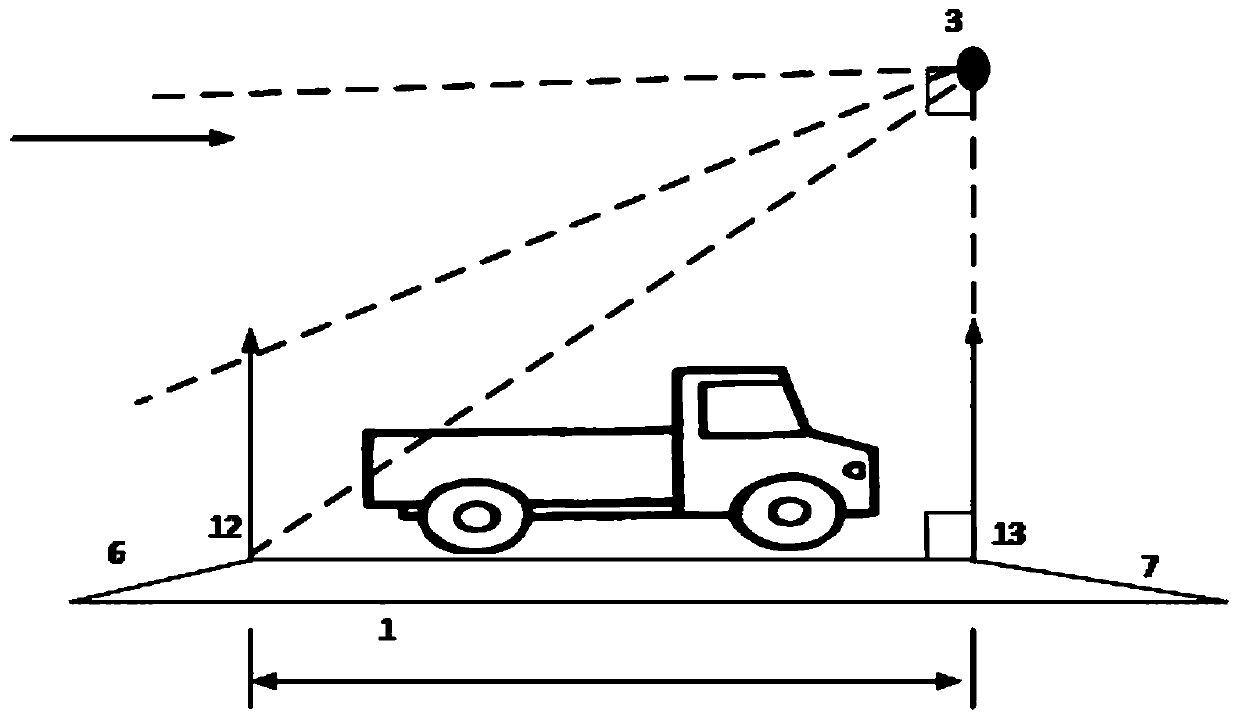

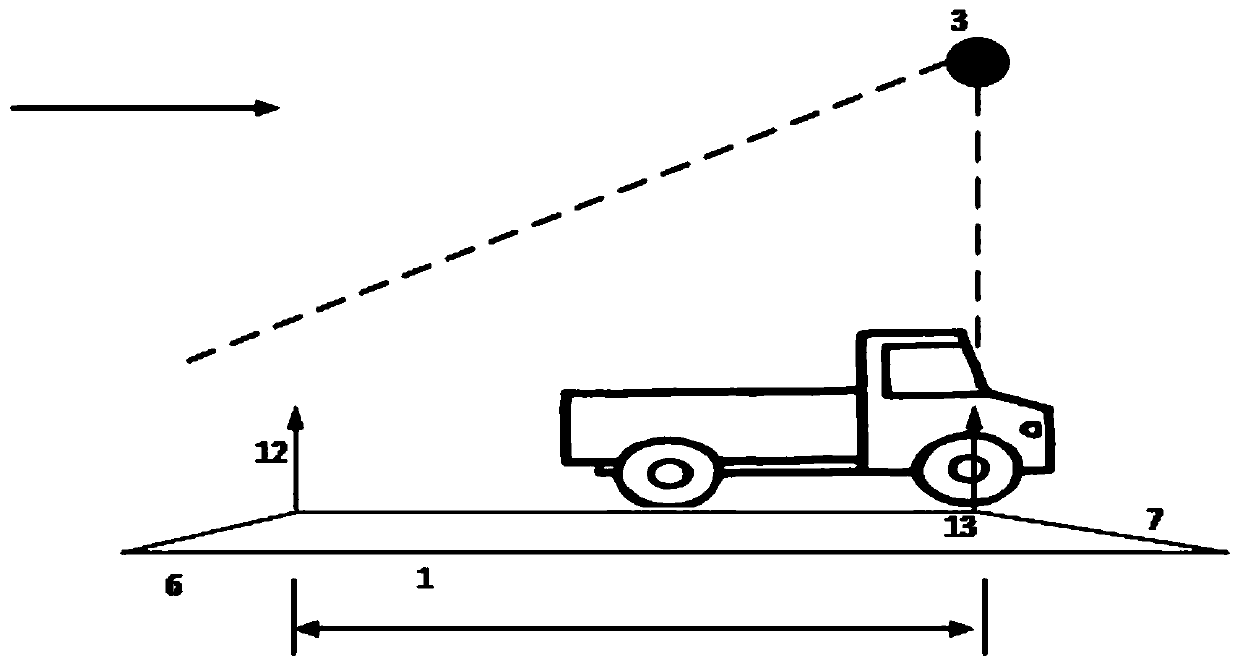

[0013] This patent application discloses a freight vehicle weighbridge monitoring method for preventing weighing cheating. This monitoring method is realized based on the following measurement system,

[0014] The metering system includes a weighbridge unit, an acquisition unit and a control processing unit 8, wherein the acquisition unit is erected above the weighbridge 1 by a gantry 2, and its composition includes a camera 4 and a laser scanning sensor connected to the control processing unit 8 cables 3. The lens of the camera 4 faces the direction in which the vehicle enters the weighbridge, and the scanning surface of the laser scanning sensor 3 is vertically downward and parallel to the driving direction of the vehicle.

[0015] A flashlight 5 is also assembled on the door frame 2, which is installed close to the camera 4, and assists the camera 4 to take pictures or capture pictures.

[0016] The weighbridge unit includes the weighbridge 1 of the platform and the weighbr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com