Automatic collecting and metering system for fuel oil discharge amount of diesel engine

An automatic collection and metering system technology, which is applied in the field of automatic collection and metering systems and marine low-speed diesel engines, can solve the problems of diesel engine fuel consumption data deviation, valves that cannot be sealed, and time delays, so as to eliminate potential safety hazards, improve metering accuracy, and maintain good performance. The effect of fault tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following describes the present invention in detail with reference to the accompanying drawings and embodiments, but the scope of protection of the present invention should not be limited thereby.

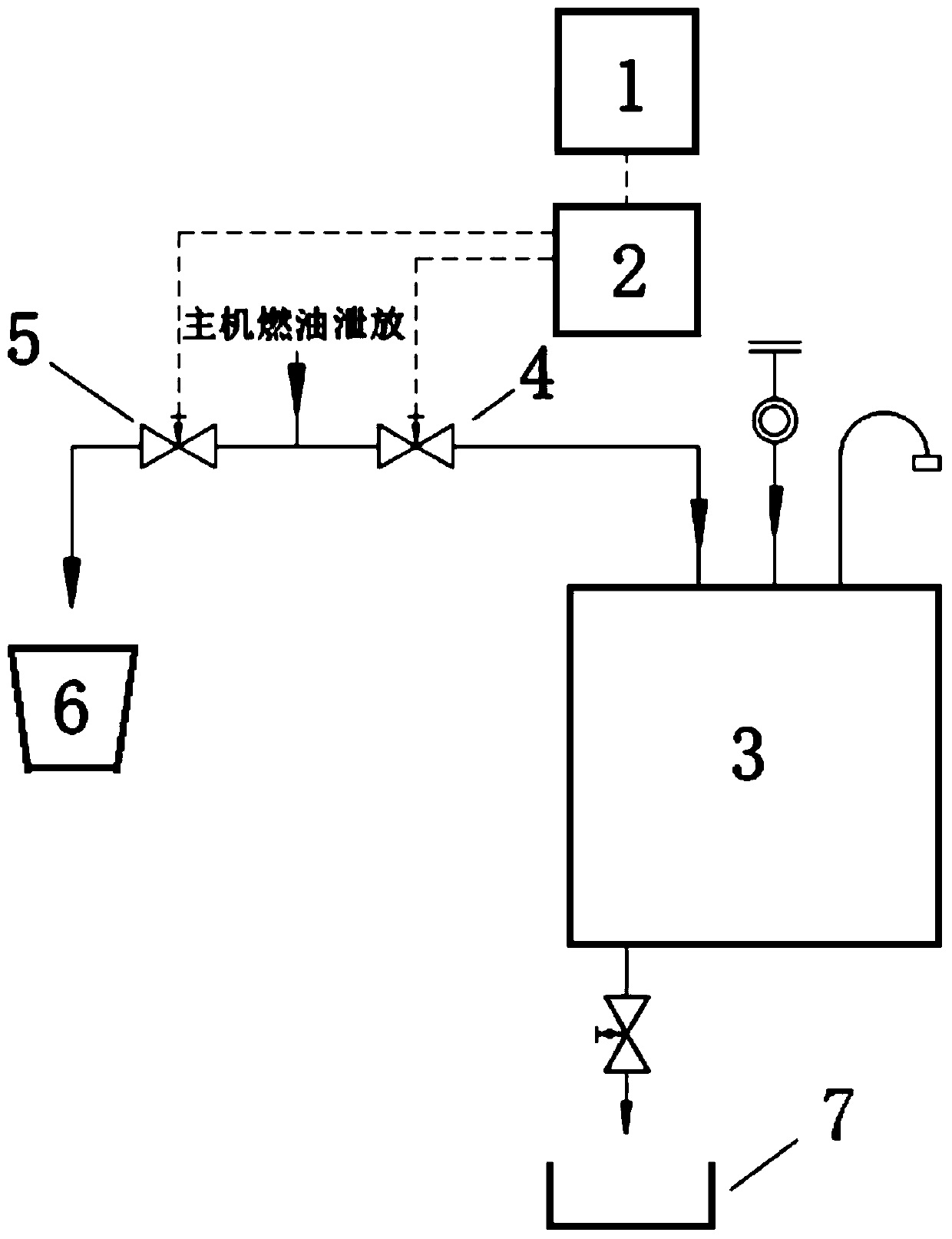

[0040] See figure 2 , The automatic collection and metering system for the diesel engine fuel drain amount includes a drain valve 4, a fuel drain tank 3, a metering valve 5, a metering barrel 6, a controller 2 and a touch screen 1.

[0041] The relief valve 4 is a solenoid valve, and the upstream is connected to a fuel drain pipe of the diesel engine, and the downstream is connected to the fuel drain tank 3 through a pipe. The metering valve 5 is an electromagnetic valve, and the upstream is connected to a fuel drain pipe of the diesel engine, and the downstream is connected to the metering barrel 6 through a pipeline. When the diesel engine is moving, during the normal non-metering period, the relief valve 4 remains normally open, and the metering valve 5 remains normally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com