Ceramic ball impact breaking rate testing machine and testing method

A ceramic ball and broken rate technology, applied in the field of ceramic ball impact resistance, can solve the problems of affecting reliability and consistency, long test period, and the inability of ordinary ceramic materials to achieve the promotion of high strength and strong operability Effect

Pending Publication Date: 2020-07-10

中国建材检验认证集团淄博有限公司

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Although the many advantages of ceramic materials are unmatched by other materials, its fatal weakness is also obvious, that is, its brittleness. The brittleness of ceramic materials affects the reliability and consistency of material performance to a large extent. These The characteristics will also appear on wear-resistant ceramic balls. Brittleness is the main factor that causes the grinding body to break. Ceramic balls for cement grinding are not suitable for ordinary ceramic materials due to their relatively harsh operating environment and working conditions.

[0003] In order to ensure that the performance of ceramic balls can meet the working

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

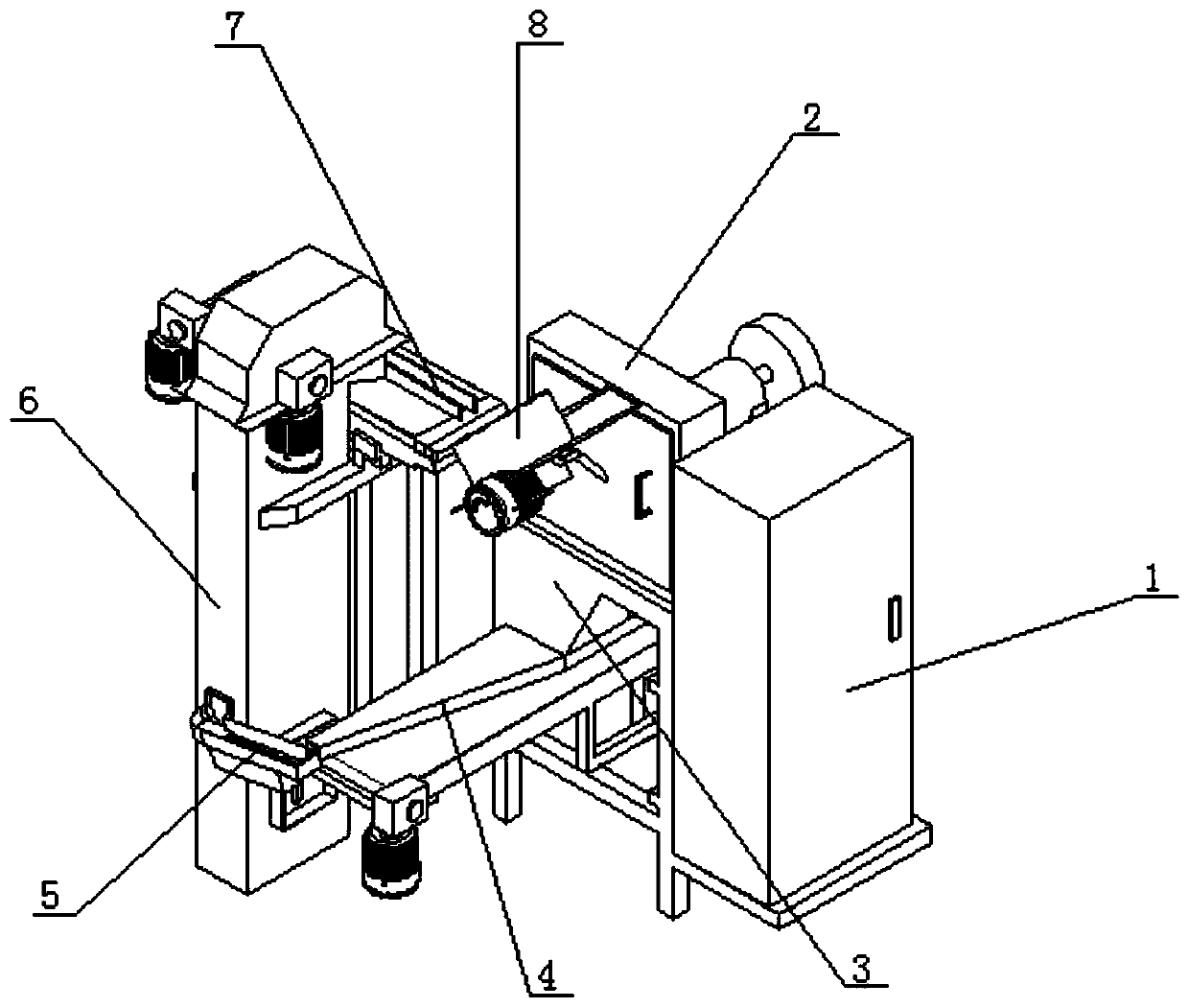

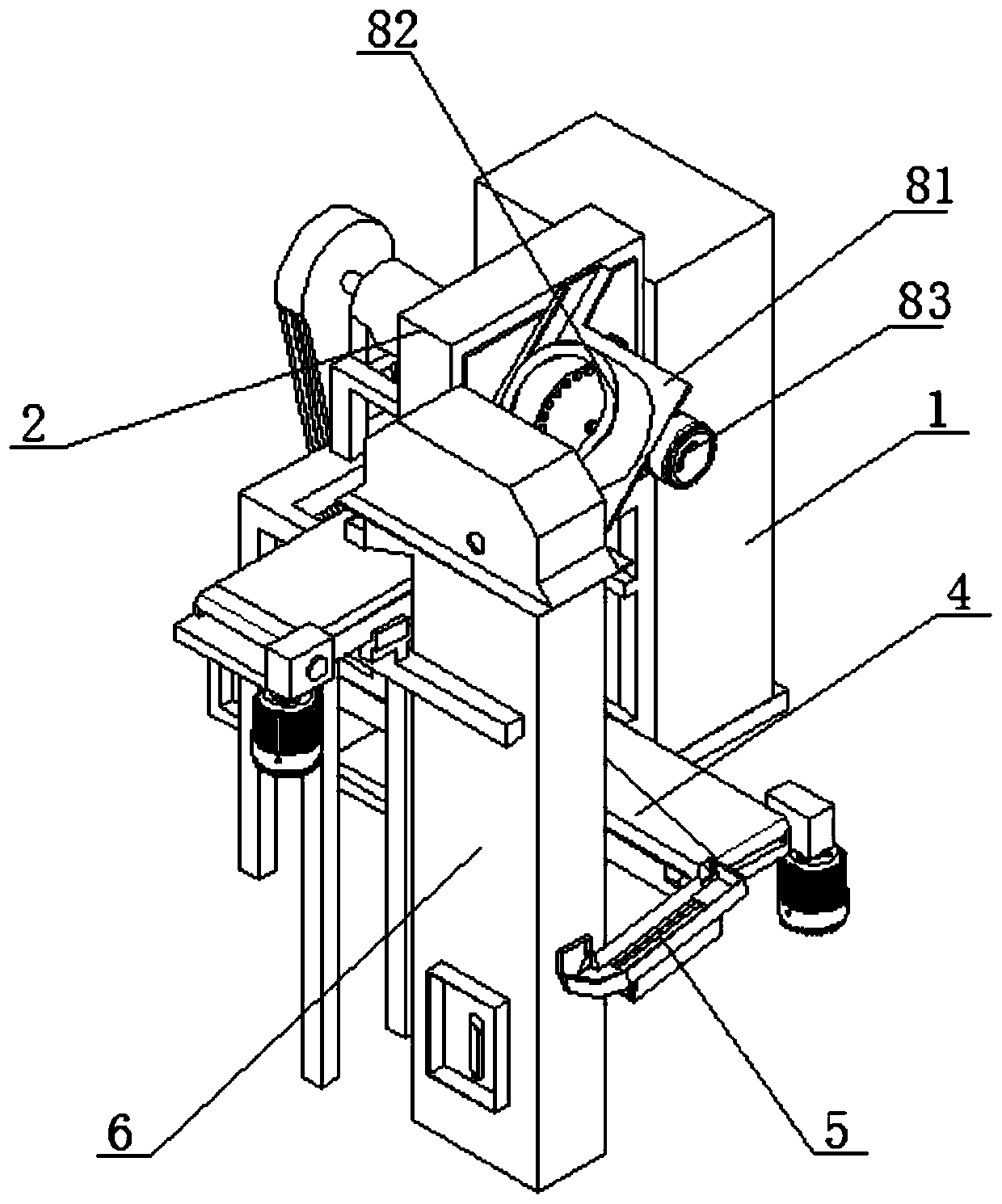

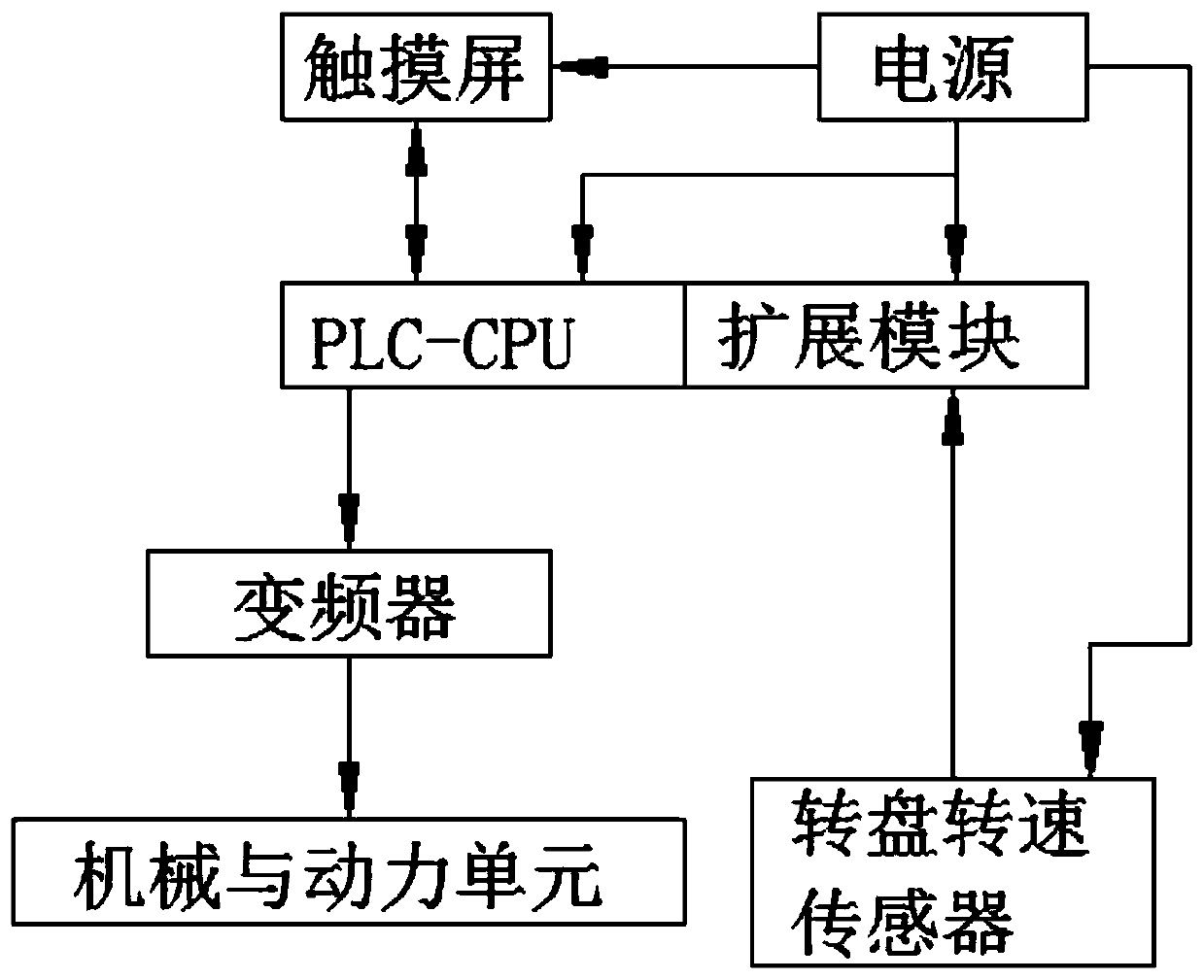

The invention discloses a ceramic ball anti-impact breakage rate testing machine and a testing method. The ceramic ball anti-impact breakage rate testing machine comprises a ball selector; a ball inlet and a ball outlet which are formed in the ball selector; a collision pool which is located below the ball selector, and the ceramic balls fall into the collision pool from the ball outlet; and a conveying assembly which is used for receiving the ceramic balls from the collision pool, one end of the conveying assembly is close to the ball selector, and the ceramic balls are transferred to the direction of the ball selector or transferred to the direction opposite to the direction of the ball selector according to instructions; the conveying assembly is provided with a screening device, and the screening device is located between the falling point for bearing the ceramic balls and the ball selector and used for screening out the ceramic balls with the minimum particle size smaller than a preset value. And the breakage rate index of the ceramic grinding body can be estimated in advance, and production and use of customers are guided.

Description

technical field [0001] The invention relates to the field of impact resistance of ceramic balls, in particular to a testing machine and a test method for impact resistance of ceramic balls. Background technique [0002] Although the many advantages of ceramic materials are unmatched by other materials, its fatal weakness is also obvious, that is, its brittleness. The brittleness of ceramic materials affects the reliability and consistency of material performance to a large extent. These The characteristics will also appear on wear-resistant ceramic balls. Brittleness is the main factor that causes the grinding body to break. Ceramic balls for cement grinding are not suitable for ordinary ceramic materials due to their relatively harsh operating environment and working conditions. [0003] In order to ensure that the performance of ceramic balls can meet the working conditions of cement grinding, it is necessary to find a special wear-resistant ceramic product. At present, th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/303G01N3/02

CPCG01N3/02G01N3/303G01N2203/001G01N2203/0033G01N2203/0067G01N2203/0073G01N2203/0208G01N2203/0276G01N2203/0676

Inventor 侯晓刚周明霞訾文娟孙高梅琳吴萍苏涛

Owner 中国建材检验认证集团淄博有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com