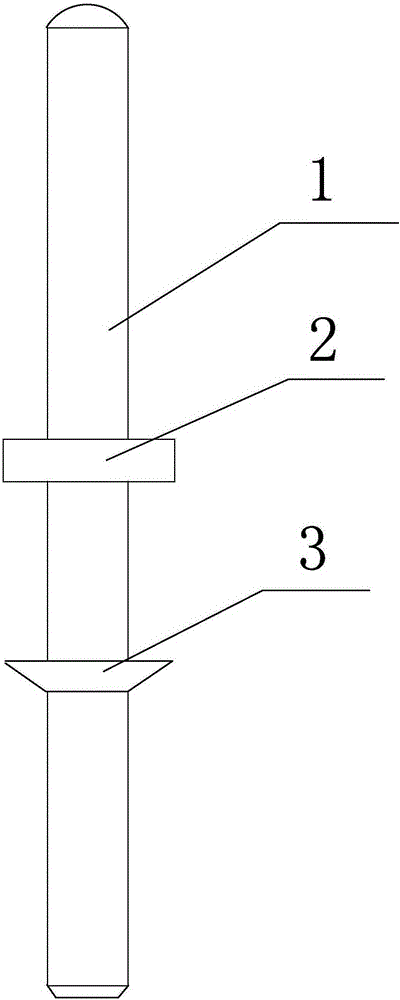

Connector in lawn mower

A connector and lawn mower technology, applied in the direction of connection, connecting device parts, contact parts, etc., can solve problems such as affecting the use of the connector, general thermal fatigue resistance, reducing the use efficiency and service life of the connector, etc. Achieve the effect of improving high strength, improving mechanical properties, and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

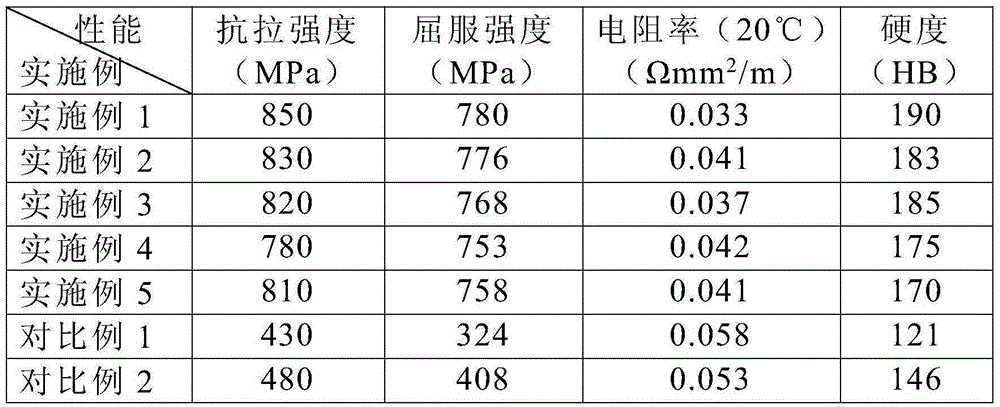

Embodiment 1

[0042] According to the raw material ingredients described in the upper surface layer, the middle layer and the lower surface layer respectively: the raw material composition (mass percentage) of the silicon nitride ceramics of the upper surface layer and the lower surface layer is 92% Si 3 N 4 and 8%Y 2 o 3 , the raw material composition (mass percentage) of the intermediate layer silicon nitride ceramics is 1.8% SiO 2 , 0.8% carbon black, 4% Y 2 o 3 , balance Si 3 N 4 ; The particle size of the carbon black is 60-80nm, SiO 2 The particle size is 0.1-0.5μm, Y 2 o 3 The particle size is 0.2-1.2μm, Si 3 N 4 α-Si for α>95% 3 N 4 .

[0043] The ingredients were impregnated with an organic carrier and sintered at 1720° C. for 1.5 h under a nitrogen pressure of 0.4 MPa to obtain dry powders of the upper surface layer, the middle layer, and the lower surface layer.

[0044] Lay the prepared dry powders of the upper surface layer, the middle layer and the lower surface ...

Embodiment 2

[0048] According to the raw material ingredients described in the upper surface layer, the middle layer and the lower surface layer respectively: the raw material composition (mass percentage) of the upper surface layer and the lower surface layer silicon nitride ceramics is 94% Si 3 N 4 and 6%Y 2 o 3 , the raw material composition (mass percentage) of the intermediate layer silicon nitride ceramics is 1.0% SiO 2 , 0.9% carbon black, 5% Y 2 o 3 , balance Si 3 N 4 ; The particle size of the carbon black is 60-80nm, and the particle size of SiO2 is 0.1-0.5 μm, Y 2 o 3 The particle size is 0.2-1.2μm, Si 3 N 4 α-Si for α>95% 3 N 4 .

[0049] The ingredients were impregnated with an organic carrier and sintered at 1710° C. for 1 hour under a nitrogen pressure of 0.5 MPa to obtain dry powders of the upper surface layer, the middle layer, and the lower surface layer.

[0050] Lay the prepared dry powder of the upper surface layer, middle layer and lower surface layer in ...

Embodiment 3

[0054] According to the raw material ingredients described in the upper surface layer, the middle layer and the lower surface layer respectively: the raw material composition (mass percentage) of the silicon nitride ceramics of the upper surface layer and the lower surface layer is 93% Si 3 N 4 and 7%Y 2 o 3 , the raw material composition (mass percentage) of the intermediate layer silicon nitride ceramics is 2.5% SiO 2 , 0.6% carbon black, 2% Y 2 o 3 , balance Si 3 N 4 ; The particle size of the carbon black is 60-80nm, SiO 2 The particle size is 0.1-0.5μm, Y 2 o 3 The particle size is 0.2-1.2μm, Si 3 N 4 α-Si for α>95% 3 N 4 .

[0055] The ingredients were impregnated with an organic carrier and sintered at 1715° C. for 2 hours under a nitrogen pressure of 0.5 MPa to obtain dry powders of the upper surface layer, the middle layer, and the lower surface layer.

[0056] Lay the prepared dry powder of the upper surface layer, middle layer and lower surface layer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com