Iron rod type golf rod head

A technology for golf clubs and club heads, which is applied to golf balls, golf clubs, rackets, etc., and can solve the problems of larger flight distance difference, larger rebound difference, unstable flight distance, etc., and achieves less deviation in flight distance , Improve the effect of rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of an iron-type golf club head according to the present invention will be described with reference to the drawings.

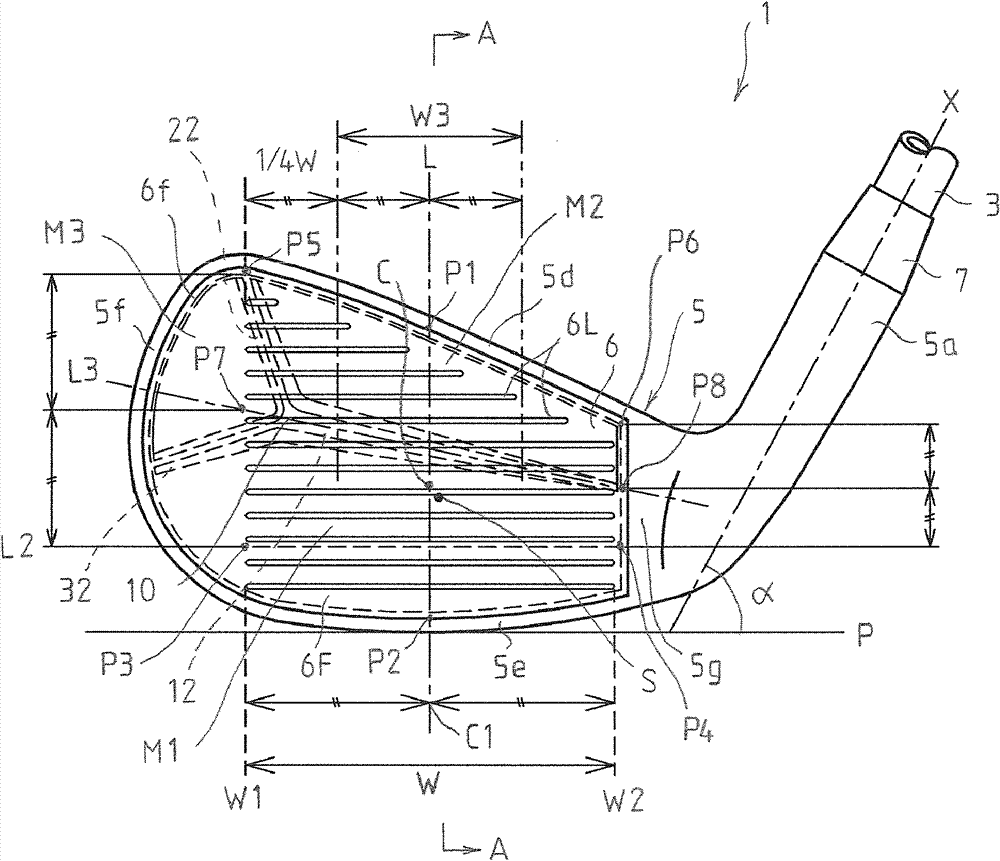

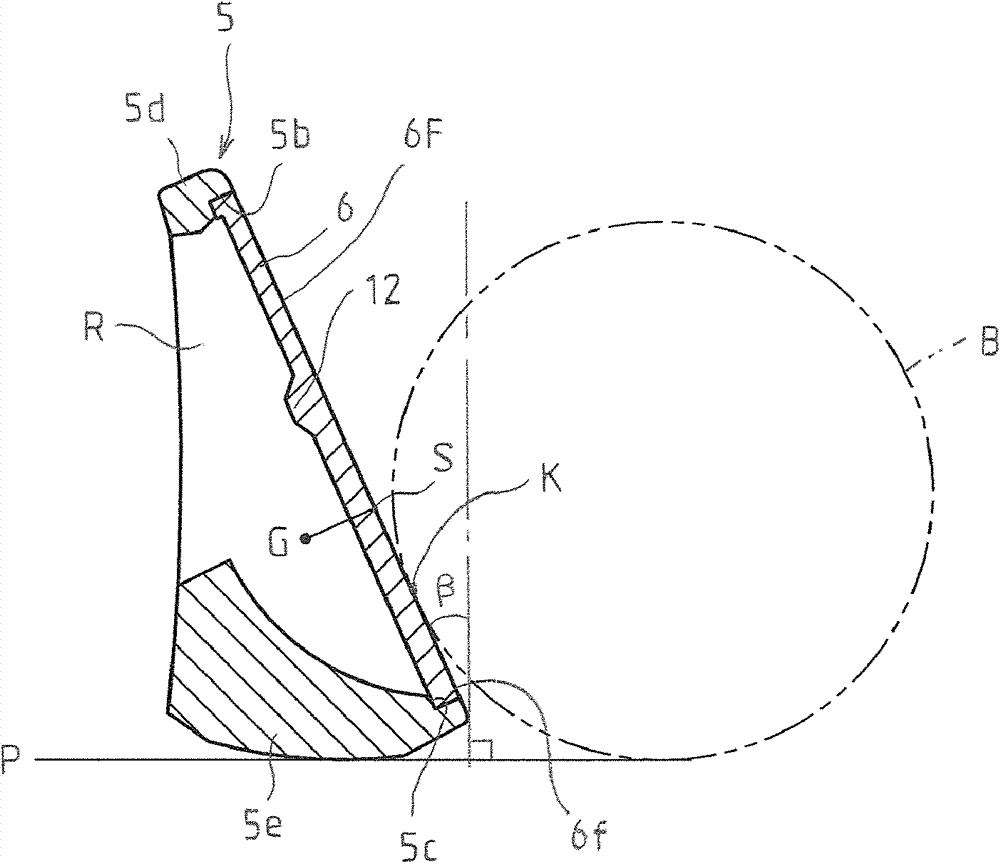

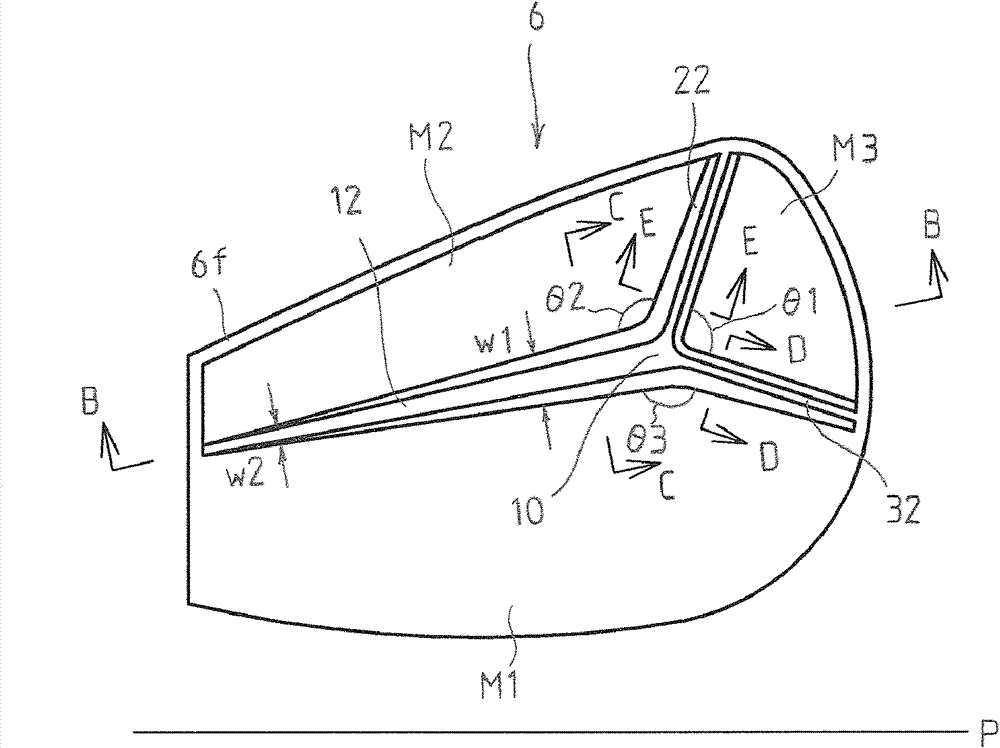

[0027] Figure 1 to Figure 3 is a diagram showing an embodiment of the present invention, figure 1 It is a front view of an iron type golf club head, figure 2 is along figure 1 A sectional view of line A-A, and, image 3 It is the figure which looked at the club surface from the back side.

[0028] The golf club head according to this embodiment includes a club head body 5 and a club surface (piece) 6 formed separately from the club head body 5, and is configured by fixing and installing the club head body 5 on the front end of the shaft 3. golf clubs1. When the club head body 5 is fixedly attached to the shaft 3 and the golf club 1 is assembled with respect to the reference horizontal plane P, a predetermined lie angle α is set between the axis X of the shaft 3 and the reference horizontal plane P.

[0029] A hosel 5a is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com