CoCrNi particle enhanced magnesium matrix composite and preparation method thereof

A particle reinforced, composite material technology, applied in the field of magnesium alloy composite materials, can solve the problems of poor plasticity and strength properties, long production process time, complicated preparation methods, etc., achieve high bending strength, enhance strain resistance, delay The effect of crack propagation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

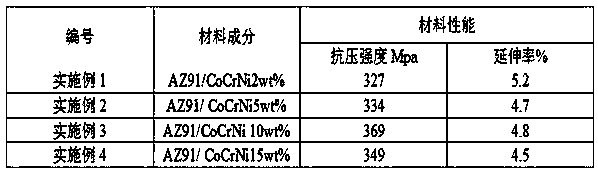

Embodiment 1

[0025] 1) Weigh 2.0g of CoCrNi powder with a size of 100μm in the middle entropy alloy and 98.0g of AZ91 alloy powder with a size of 50μm;

[0026] 2) Put the raw materials weighed in step 1) into a ball mill, add 500g of stainless steel balls, vacuumize and fill with argon, repeat two or three times and then carry out ball milling at a speed of 50r / min. After 2 hours of ball milling, the powder is mixed evenly to obtain a mixed powder;

[0027] 3) Put the mixed powder obtained in step 2) into SPS equipment for sintering, raise the temperature to 500°C at a heating rate of 50°C / min, keep it warm for 10 minutes, then cool it down to room temperature at 50°C / min, and finally obtain a magnesium-based composite material , and then the composite material is made into a sample to obtain a prefabricated sample.

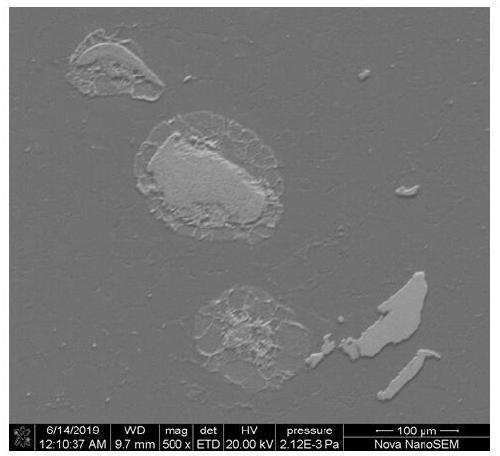

[0028] The magnesium-based composite material obtained in this embodiment is observed under a scanning electron microscope, and the results are as follows: figure 1 shown. ...

Embodiment 2

[0031] 1) Weigh 5.0g of CoCrNi powder with a size of 200μm of medium entropy alloy and 95.0g of AZ91 alloy powder with a size of 60μm;

[0032] 2) Put the raw materials weighed in step 1) into a ball mill, add 500g of stainless steel balls, vacuumize and fill with argon, repeat two or three times and then carry out ball milling at a speed of 50r / min. After 2 hours of ball milling, the powder is mixed evenly to obtain a mixed powder;

[0033] 3) Put the mixed powder obtained in step 2) into SPS equipment for sintering, raise the temperature to 500°C at a heating rate of 50°C / min, and keep it at a pressure of 75MPa for 10 minutes, then cool it down to room temperature at 50°C / min, and finally obtain magnesium After the composite material is made into a sample, a prefabricated sample is obtained.

Embodiment 3

[0035] 1) Weigh 10.0g of CoCrNi powder with a size of 120μm of medium entropy alloy and 90.0g of AZ91 alloy powder with a size of 70μm;

[0036] 2) Put the raw materials weighed in step 1) into a ball mill, add 500g of stainless steel balls, vacuumize and fill with argon, repeat two or three times and then carry out ball milling at a speed of 50r / min. After 2 hours of ball milling, the powder is mixed evenly to obtain a mixed powder;

[0037] 3) Put the mixed powder obtained in step 2) into SPS equipment for sintering, raise the temperature to 500°C at a heating rate of 50°C / min, and keep it at a pressure of 75MPa for 10 minutes, then cool it down to room temperature at 50°C / min, and finally obtain magnesium After the composite material is made into a sample, a prefabricated sample is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com