A kind of high-strength ultra-fine twinned pure titanium and its preparation method

An ultra-fine-grained pure titanium and high-strength technology, which is applied in the field of high-strength ultra-fine twin-crystal pure titanium and its preparation, can solve the problems of decreased toughness, increased strength, and unfavorable material application of pure titanium materials, so as to improve high strength and high strength. The effect of high toughness, avoiding oxidation and improving comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing high-strength ultrafine twinned pure titanium, comprising the following steps:

[0030] 1) Perform high-energy pulse treatment on pure titanium rods to obtain equiaxed pure titanium;

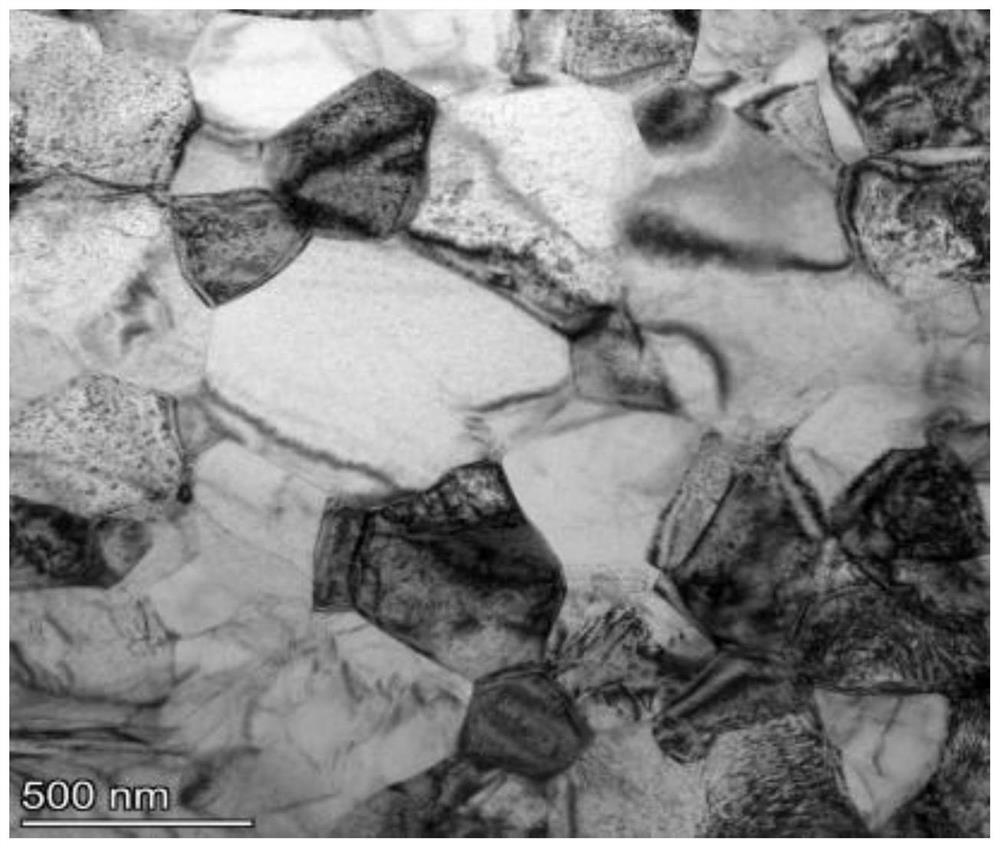

[0031] 2) annealing the equiaxed pure titanium obtained in step 1) to obtain equiaxed ultrafine-grained pure titanium;

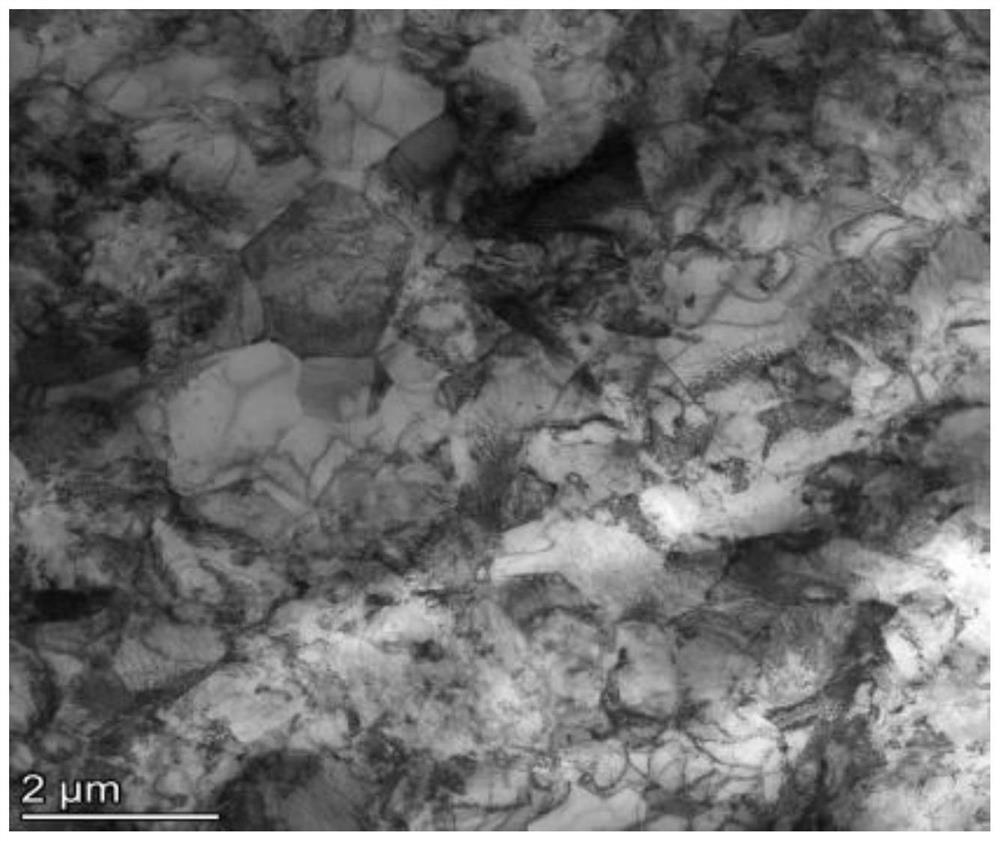

[0032] 3) performing pre-deformation treatment on the equiaxed ultra-fine-grained pure titanium obtained in step 2) to obtain ultra-fine twinned pure titanium.

[0033] In the present invention, the high-energy pulse treatment includes: placing the pure titanium rod in a high-energy pulse device with a frequency of 60-760 Hz, a voltage of 10-600 V, a pulse width of 50-5000 μs, and a current density of 200 A / mm 2 ~6000A / mm 2 ; Preferably, the frequency is 100-660Hz, the voltage is 50-500V, the pulse width is 500-3000μs, and the current density is 500A / mm 2 ~5000A / mm 2 ; More preferably, the frequency is 200-500Hz, the vol...

Embodiment 1

[0044] The preparation method of high-strength ultra-fine twinned pure titanium is as follows:

[0045] 1) Set the high-energy pulse parameters as: frequency 500Hz, voltage 50V, pulse width 50μs, current density 200A / mm 2 . Perform high-energy pulse current treatment on pure titanium rods to obtain equiaxed pure titanium with uniform distribution of microstructure;

[0046] 2) Annealing the equiaxed pure titanium obtained in the previous step at a low temperature of 300°C for 5 minutes in a vacuum tube furnace to obtain equiaxed ultrafine-grained pure titanium;

[0047] 3) The equiaxed ultra-fine-grained pure titanium obtained in the previous step was subjected to uniaxial tensile loading on a tensile machine at room temperature, and the tensile strain rate was 5.0×10 -4 the s -1 , the equiaxed ultra-fine-grained pure titanium is loaded to an engineering strain of 8% and then unloaded, and the sample is removed after complete unloading to obtain high-strength ultra-fine twi...

Embodiment 2

[0049] The preparation method of high-strength ultra-fine twinned pure titanium is as follows:

[0050] 1) Set the high-energy pulse parameters as: frequency 200Hz, voltage 200V, pulse width 50μs, current density 500A / mm 2 . Perform high-energy pulse current treatment on pure titanium rods to obtain equiaxed pure titanium with uniform distribution of microstructure;

[0051] 2) Anneal the equiaxed pure titanium obtained in the previous step at a low temperature of 320°C for 6 minutes in a vacuum tube furnace to obtain equiaxed ultrafine-grained pure titanium;

[0052] 3) The equiaxed ultra-fine-grained pure titanium obtained in the previous step was subjected to uniaxial tensile loading on a tensile machine at room temperature, and the tensile strain rate was 30×10 -4 the s -1 , the equiaxed ultra-fine-grained pure titanium is loaded to an engineering strain of 10% and unloaded, and the sample is removed after complete unloading to obtain high-strength ultra-fine twinned pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com