Centrifugal casting tool for high-strength worm gear and using method of centrifugal casting tool

A centrifugal casting, high-strength technology, applied in the field of worm gear casting equipment, can solve the problems of inconvenient adjustment of the pouring angle, unfavorable long-term use, lack of long-term usability, etc., to increase rapid closure, facilitate long-term use, and the overall structure is convenient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

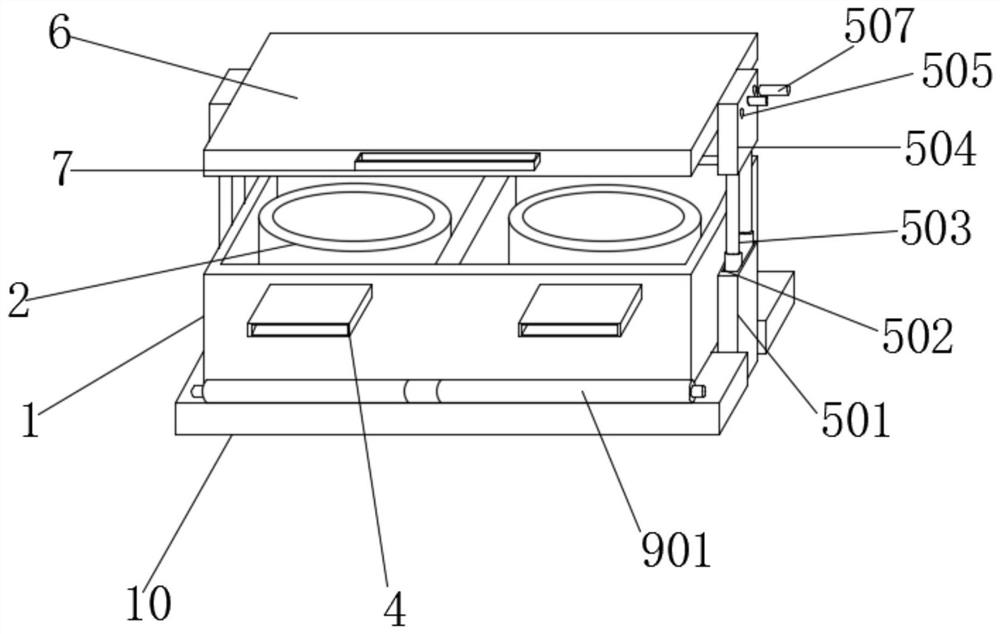

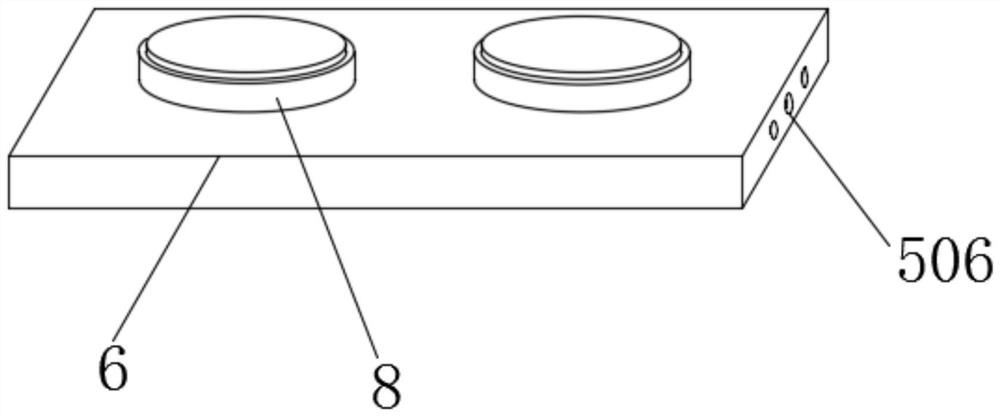

[0032] see Figure 1-5 As shown, a schematic diagram of the overall structure of a centrifugal casting tool for a high-strength worm gear and its use method includes a housing 1, a high-strength closure assembly, an adjustment assembly, and a lifting assembly. The housing 1 is detachably connected to a centrifugal cylinder 2, The surface of the shell 1 is connected with a high-strength sealing component, the surface of the shell 1 is connected with an adjustment component, and one side of the surface of the shell 1 is connected with a lifting component;

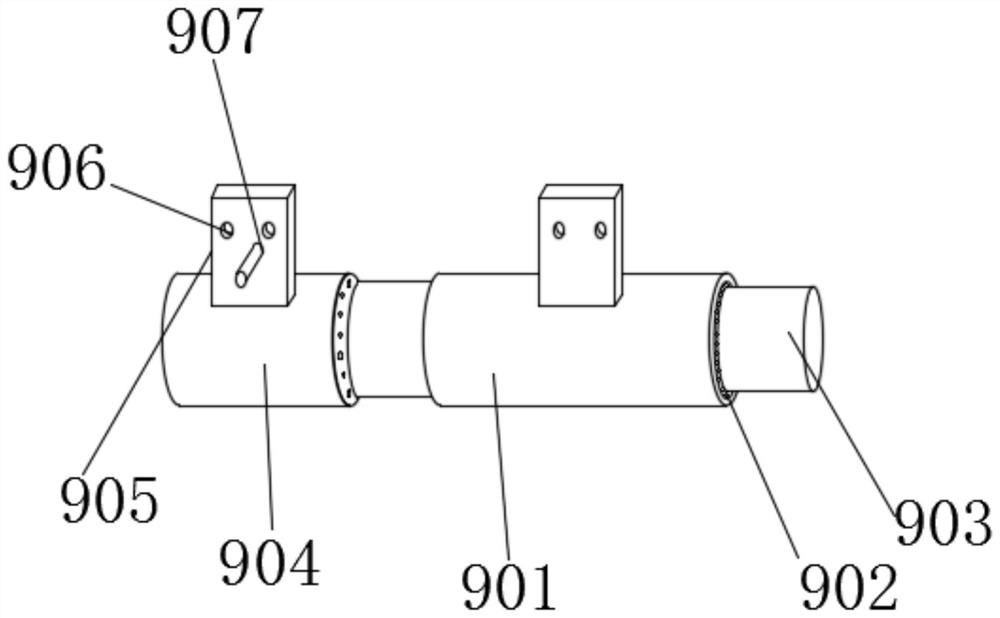

[0033] The high-strength sealing assembly includes a first connecting seat 501, which is detachably connected to both sides of the surface of the housing 1. A cavity 502 is opened inside the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com