Building shutter

A technology for building formwork and panels, which is used in the manufacture of building materials, veneer sheets, household components, etc., can solve the problems of discarding waste vinyl films and low production efficiency, and achieve the effects of reducing waste problems, improving strength and excellent strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

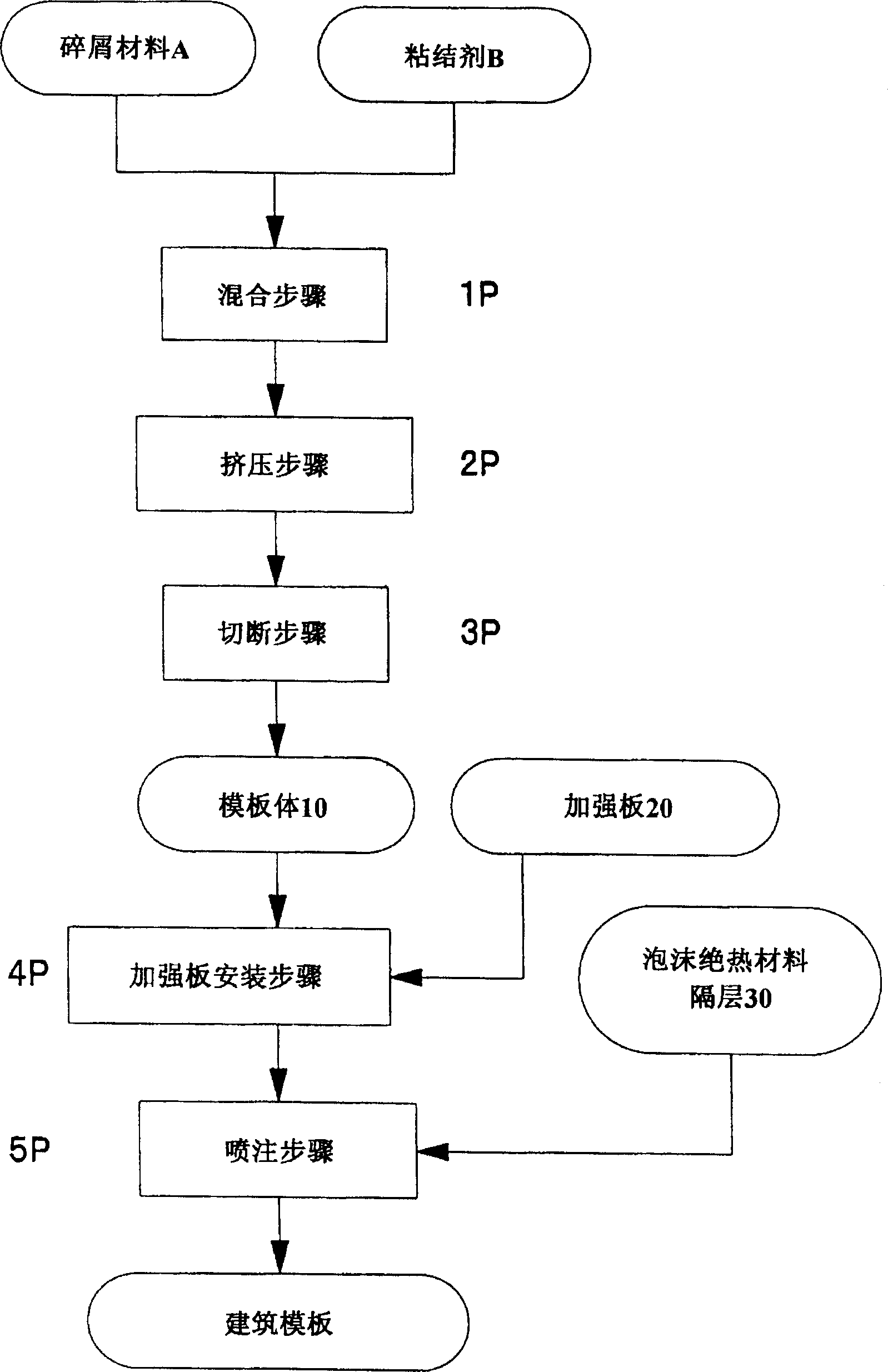

[0037] A preferred embodiment of the present invention will be described below with reference to the accompanying drawings.

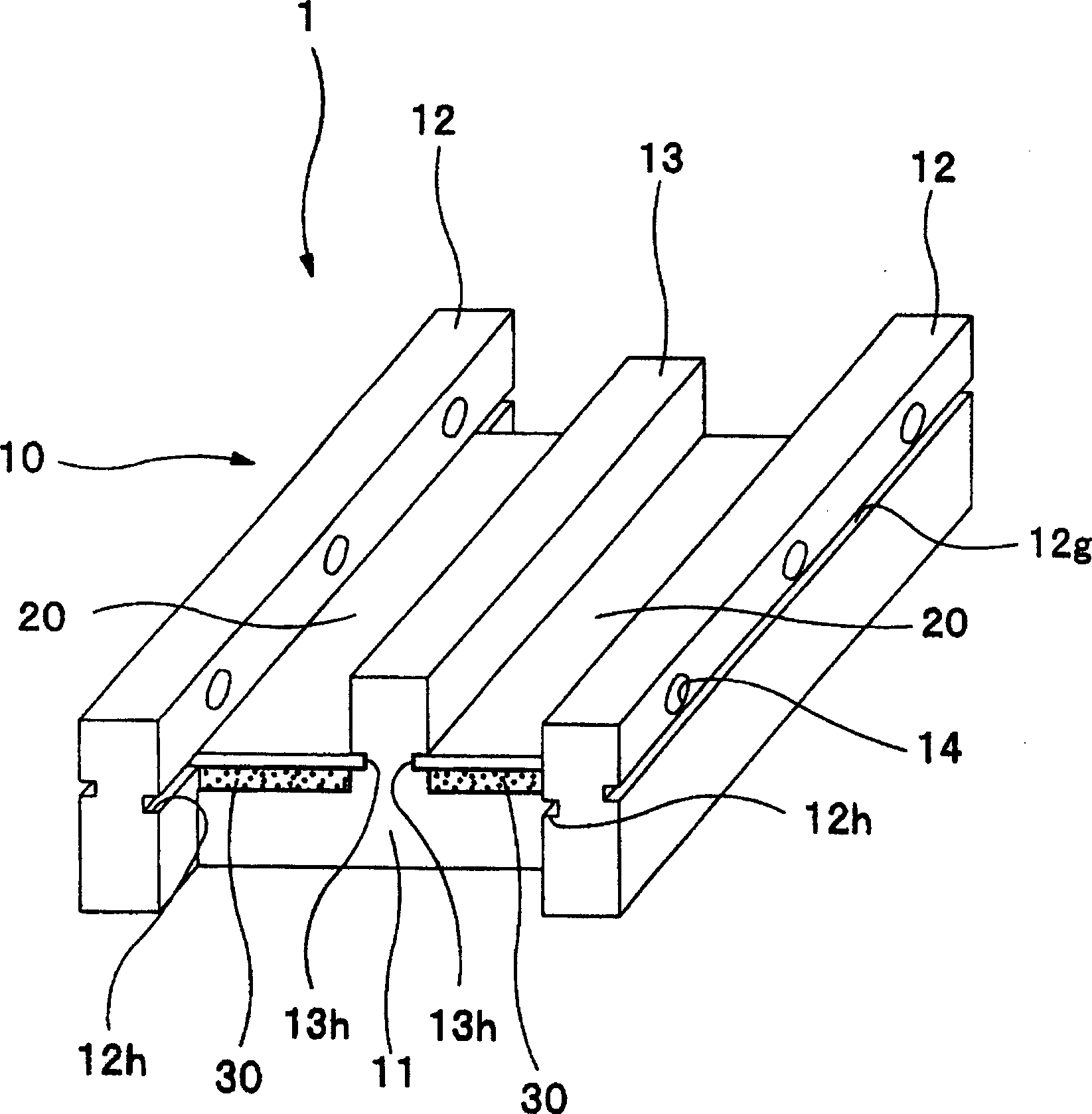

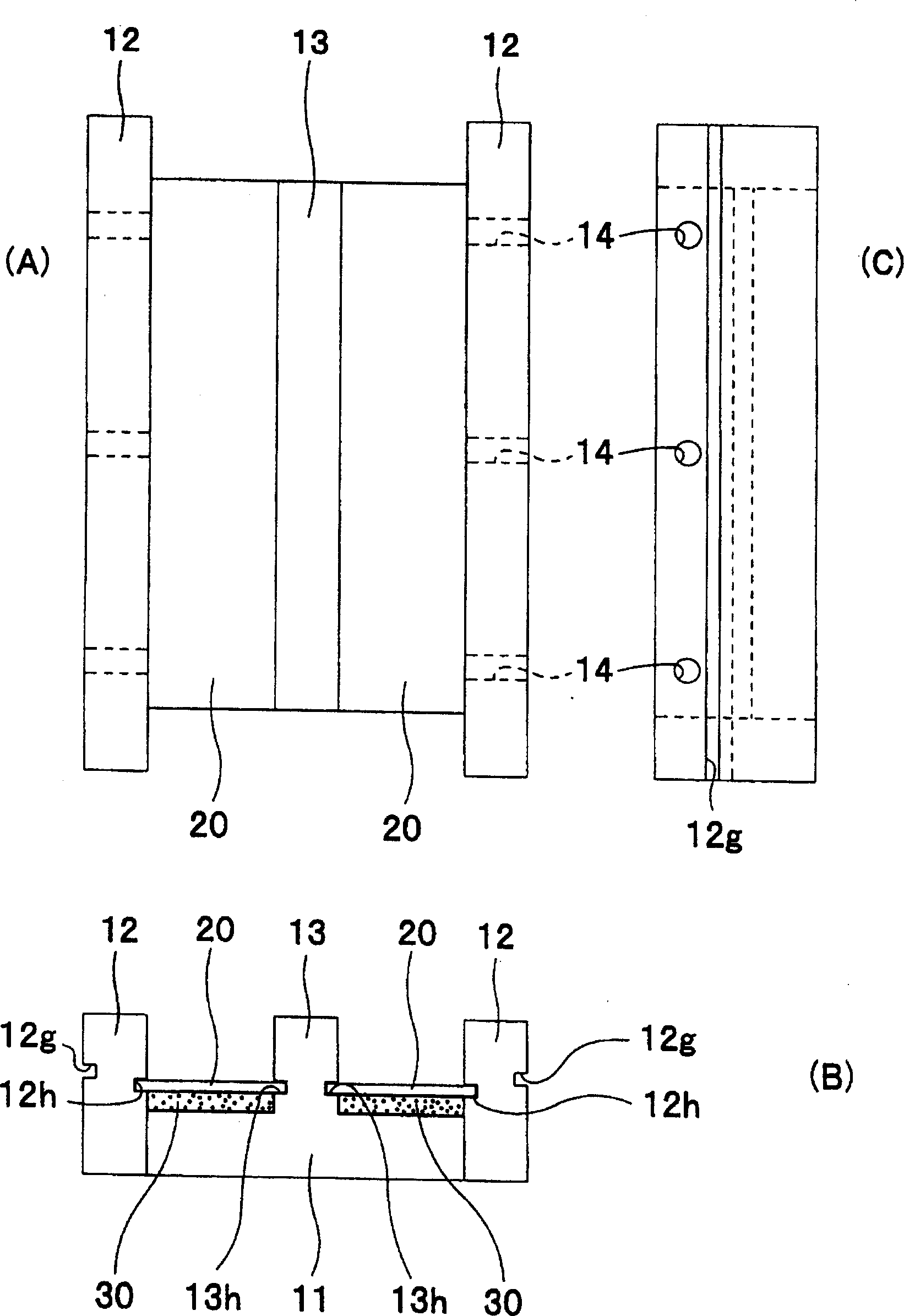

[0038] like figure 1 and 2 As shown, the building formwork 1 includes a formwork body 10 , a pair of reinforcement panels 20 and a pair of foam insulation material partitions 30 .

[0039] First, the template body 10 will be described.

[0040] The formwork body 10 includes a panel 11 , a pair of longitudinal frames 12 and 12 , and a formwork rib 13 . The panel 11, the pair of longitudinal frames 12 and 12 and the formwork ribs 13 are extruded into a single piece from a mixture of wood and / or bamboo chips and a binder. Details of extrusion molding will be described later.

[0041] The panel 11 of the template body 10 is a flat square plate extending along the extruding direction.

[0042] A pair of longitudinal frames 12 and 12 are formed on the left and right sides of the panel 11 along the extrusion direction.

[0043] On the inner side of each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com