On-site positioning system and method for equipment in cabinet, and operation and maintenance management system and method

A positioning system and cabinet technology, applied in surveying and navigation, special data processing applications, instruments, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effect of improving positioning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

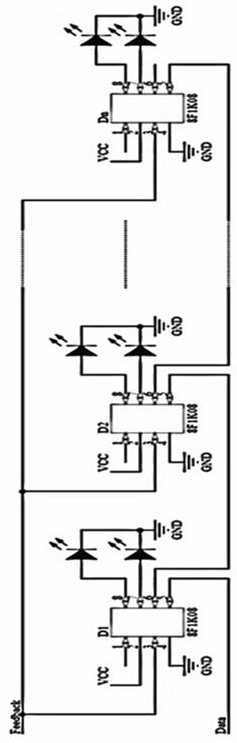

[0041] 1) Equipment status indication system

[0042] The upper computer and the equipment status indication system connected with the upper computer cooperate to realize the precise point-to-point positioning of the equipment in the cabinet. The equipment status indication system includes equipment status indication circuits installed on each cabinet, and each equipment status indication circuit is composed of equipment status indication modules corresponding to each device; the equipment status indication modules are installed one by one corresponding to the position of the equipment in the cabinet. On the cabinet or on the equipment in the cabinet; the equipment status indication module can receive the equipment status display instruction sent by the host computer to display the corresponding equipment status, and the equipment status includes the operation and maintenance status of maintenance and maintenance.

[0043] The device status indicating modules in each device st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com