Ratchet wrench

A technology of ratchet wrench and wrench body, applied in the field of ratchet wrench, which can solve the problems of low strength, short service life, and small toughness, and achieve the effects of low manufacturing cost, improved torque and service life, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

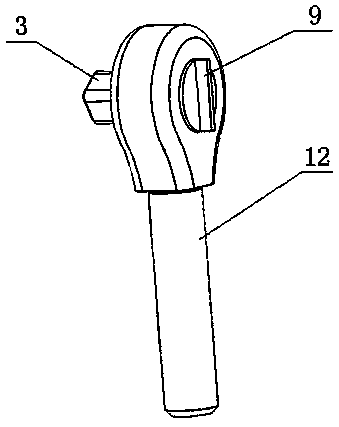

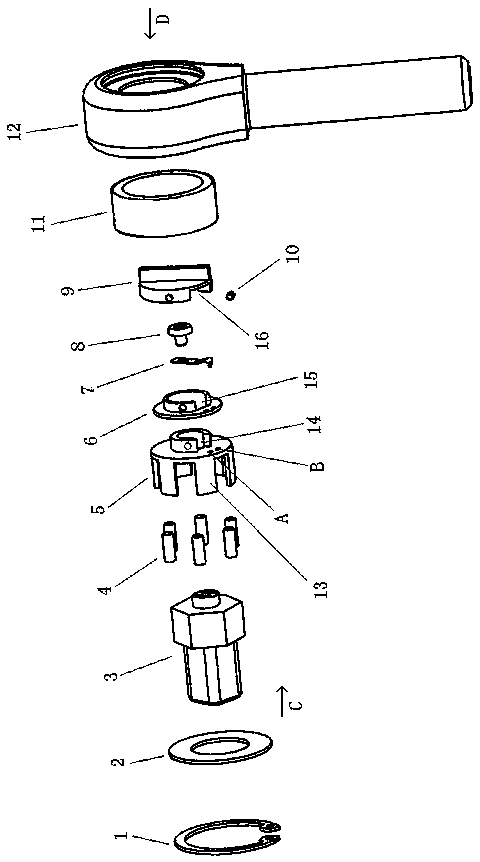

[0015] see figure 1 , figure 2 , image 3 As shown, the appearance of the present invention is basically the same as that of the existing ratchet wrench, including a wrench body 12, a toothed outer ring bearing sleeve 11 is arranged in the round hole at the head of the wrench body 12, and a rotor assembly is arranged in the bearing sleeve 11 , the rotor assembly includes the angle wheel rotor 3 and the bearing roller 4, the lower structure of the angle wheel rotor 3 is a square bar, which is convenient for connecting the sleeve, and the head part of the angle wheel rotor 3 located in the bearing sleeve 11 is a regular hexagon body (the angular number of the angular wheel rotor can be arbitrary, such as triangular, quadrangular, pentagonal, hexagonal, heptagonal, etc., in this example, the commonly used hexagonal is used to describe), and the six bearing rollers are arranged in six corners of the hexagon. Wall surface; the rotor assembly also includes a positioning sleeve 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com