Aluminum alloy section for new energy automobile framework

A technology for aluminum alloy profiles and new energy vehicles, applied in vehicle parts, superstructure, transportation and packaging, etc., can solve problems such as low safety strength, and achieve the effect of good safety strength and high bending resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

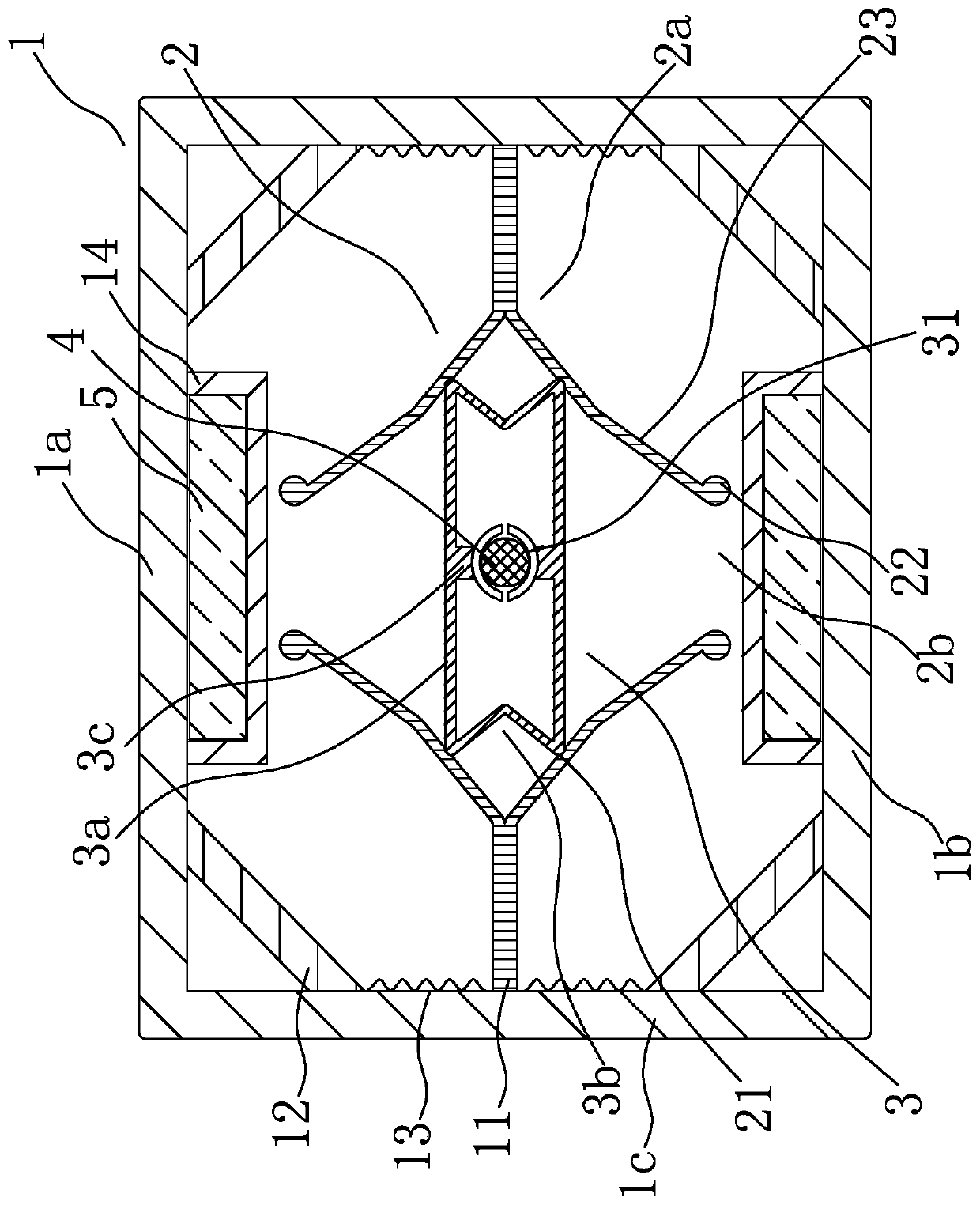

[0020] refer to figure 1 , an aluminum alloy profile for a new energy vehicle skeleton, comprising an outer frame 1, a middle frame 2, and an inner frame 3 of a square structure, the outer frame 1 has a top edge 1a, a bottom edge 1b, and two side edges 1c, the The middle frame 2 includes a set of closed diagonal corners 2a and a set of open diagonal corners 2b. The outer frame 1 extends inward from the middle of the two sides 1c to form a closed pair of connecting sides 11 and the middle frame 2. The corners 2a are connected, specifically, the outer frame 1, the connecting edge 11 and the middle frame 2 are integrally formed during production;

[0021] The middle part of each side of the middle frame 2 is provided with a concave embedding groove 21, and the inner frame 3 is integrally embedded in the embedding groove 21 on each side of the middle frame 2, and the inner frame 3 includes a set of Straight-line opposite sides 3a and a group of broken-line opposite sides 3b, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com