Rapid painting device for building wall surface

A wall surface and fast technology, which is applied in the direction of construction and building construction, can solve the problems of poor painting effect of building walls, low work efficiency, and work fatigue, so as to improve the effect and efficiency, facilitate movement, and reduce construction difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

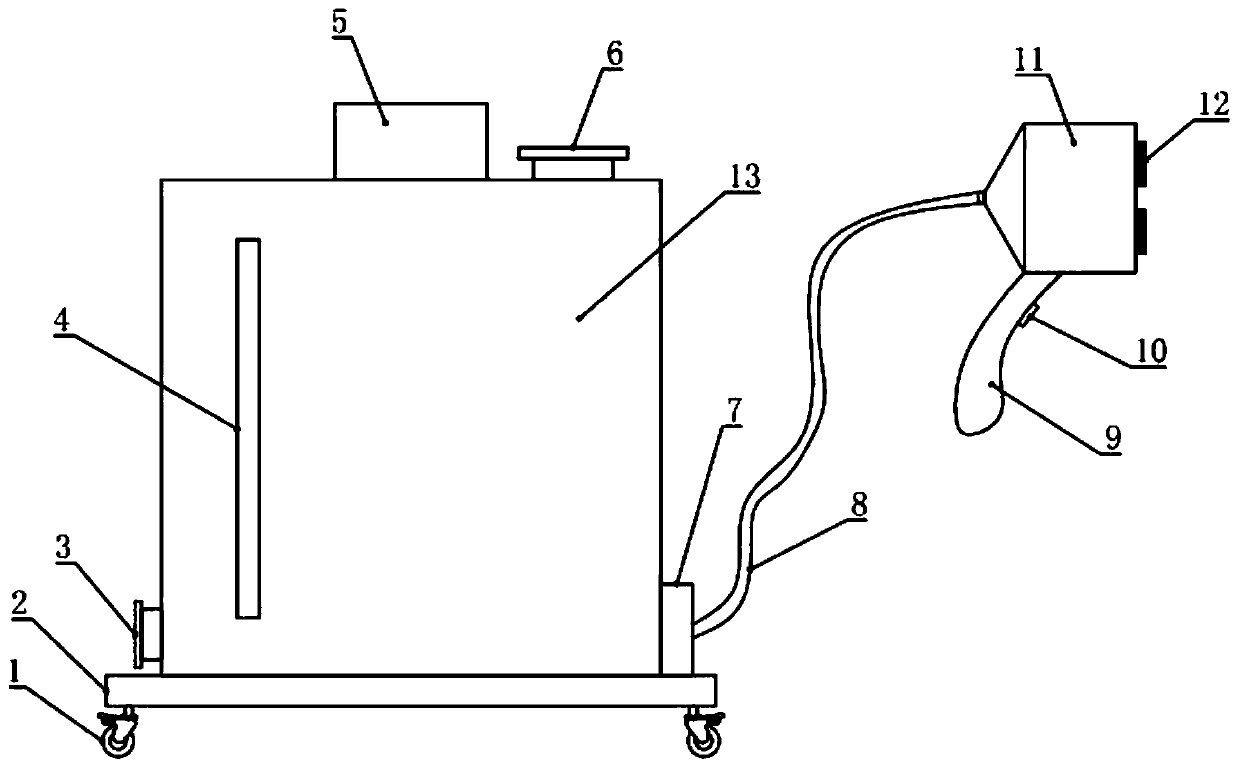

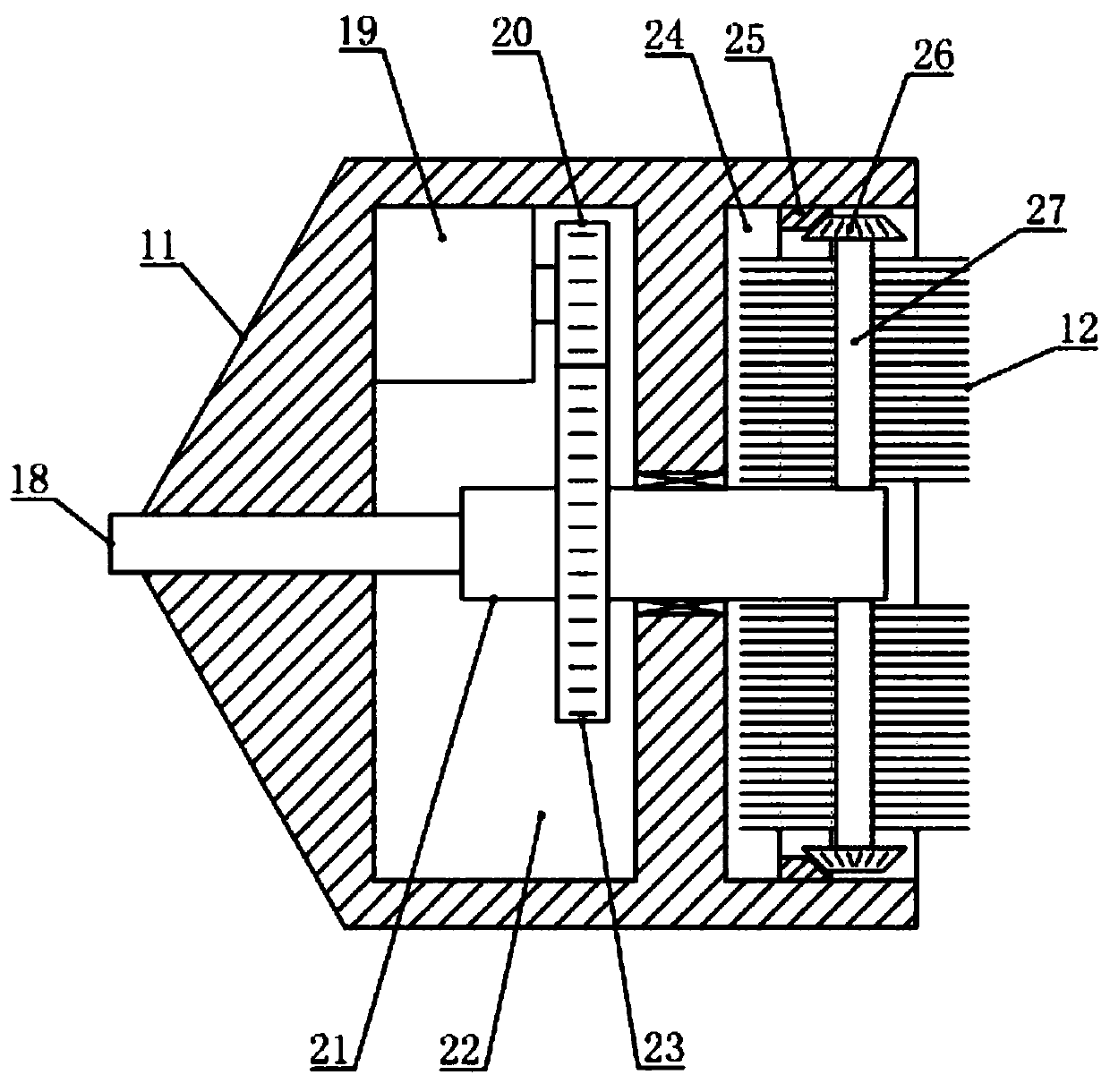

[0020] see figure 1 , 3 And 4, in the embodiment of the present invention, a kind of fast painting device for building walls includes a base plate base 2, a mixing supply box 13 is installed on the base plate base 2, and a delivery pump 7 is installed at the bottom of the mixing supply box 13, The conveying pump 7 is connected with the feed pipe 18 installed on the paint casing 11 through the feed pipe 8, and the rotating pipe 21 connected with the feed pipe 18 is also installed in the paint casing 11. A driving chamber 22 and a painting chamber 24 are provided respectively. The driving chamber 22 of the painting housing 11 is provided with a driving mechanism for driving the rotating tube 21 to rotate. The end of the rotating tube 21 away from the material guide pipe 18 is provided with a paint outlet. 28. The end of the rotating tube 21 away from the material guide pipe 18 is also rotated and installed with a plurality of painting rods 27 in a circumferential distribution. ...

Embodiment 2

[0024] see Figure 1-6 , the difference between this embodiment and embodiment 1 is:

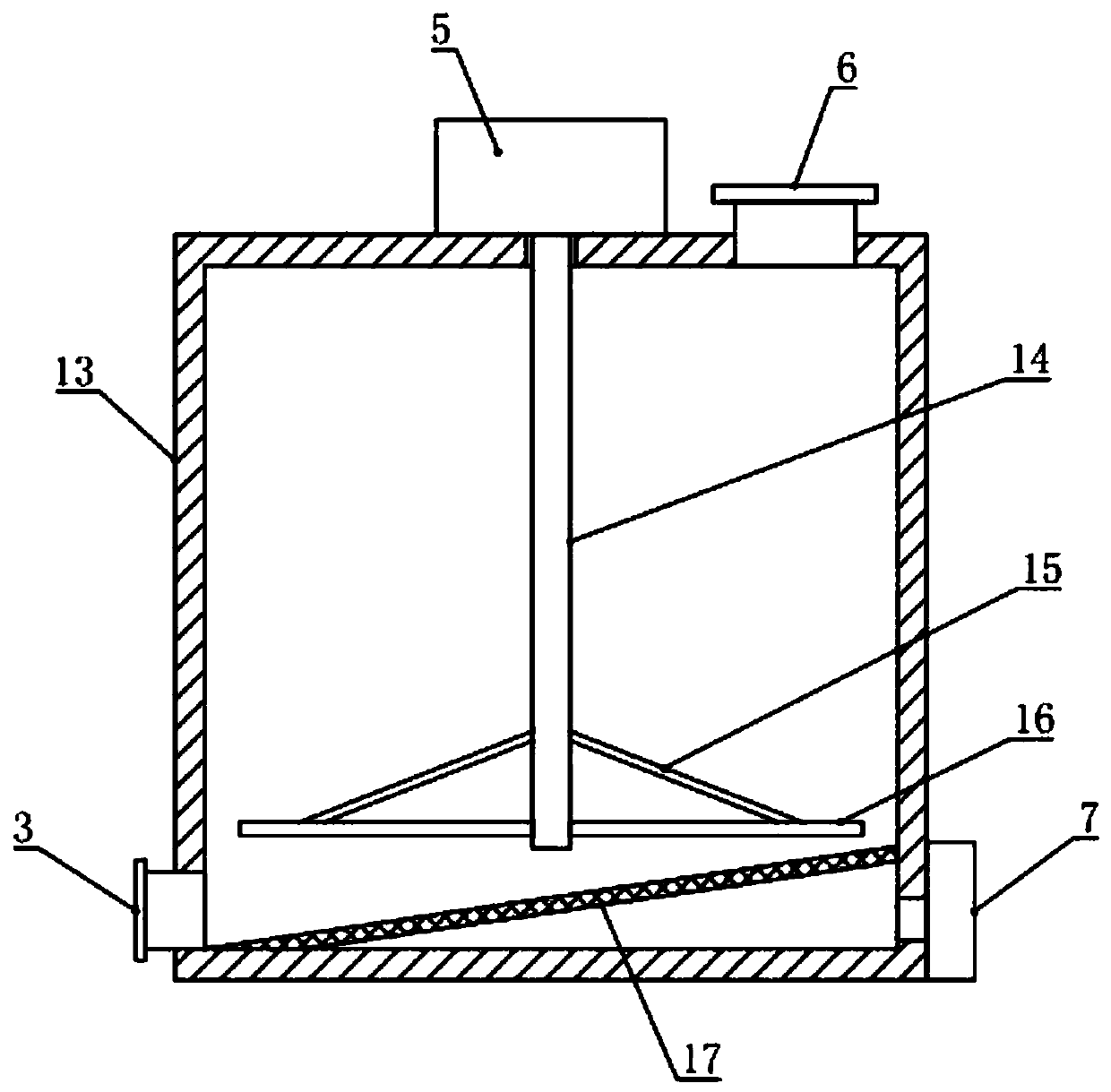

[0025] In this example, if Figure 1-2 As shown, the middle part of the mixing supply box 13 is equipped with a stirring shaft 14, and the top of the mixing supply box 13 is provided with a mixing motor 5 for driving the stirring shaft 14 to rotate, and the lower end of the stirring shaft 14 is circumferentially A plurality of stirring rods 16 are distributed and installed, and the stirring rods 16 are arranged horizontally. The upper side of the stirring rods 16 is fixed with a diagonal strut 15, and the inner end of the diagonal strut 15 is fixed on the stirring shaft 14. Rod 16 cooperates and has better mixing effect to coating.

[0026] The inner bottom of the mixing supply box 13 is equipped with a filter screen 17 with one end inclined downwards. The aperture and material of the filter screen 17 can be disclosed and not specifically limited; the lower end of the filter screen 17 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com