Excavating method for bucket wheel excavator in open-pit mine rib spalling area

An excavator and wheel bucket technology, which is applied in the field of open-pit mining, can solve the problems of limited working space, scraping, poor operation adaptability and flexibility in the gang area, and achieve the effect of improving production safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0018] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

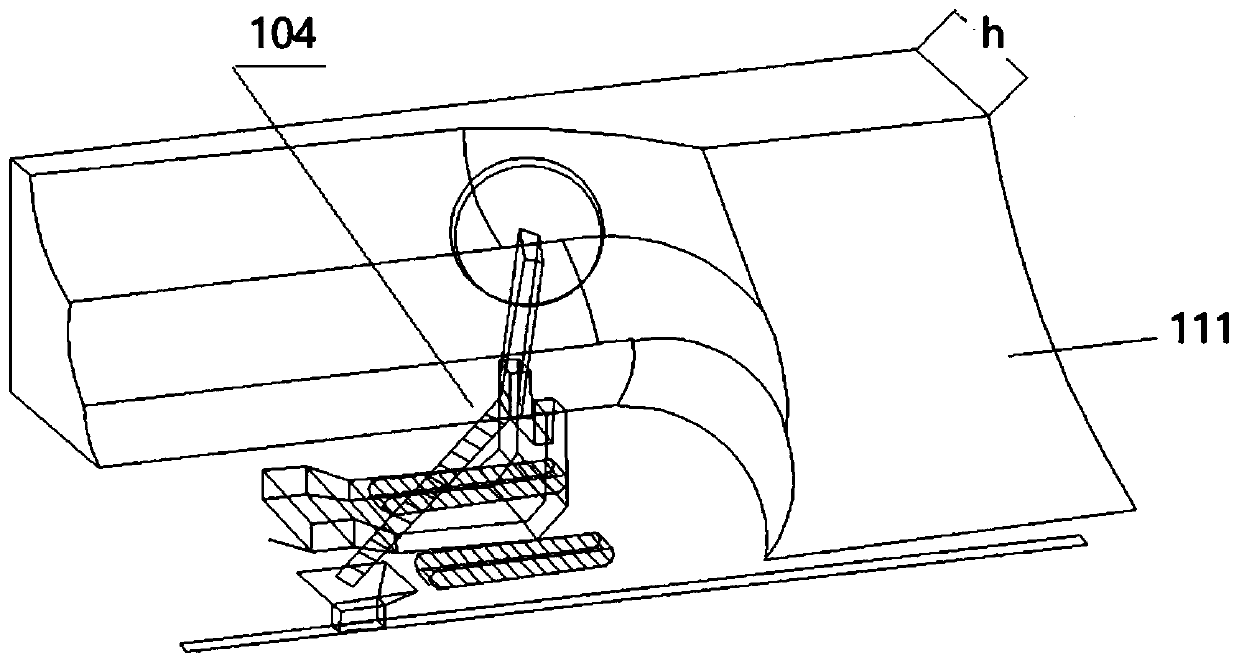

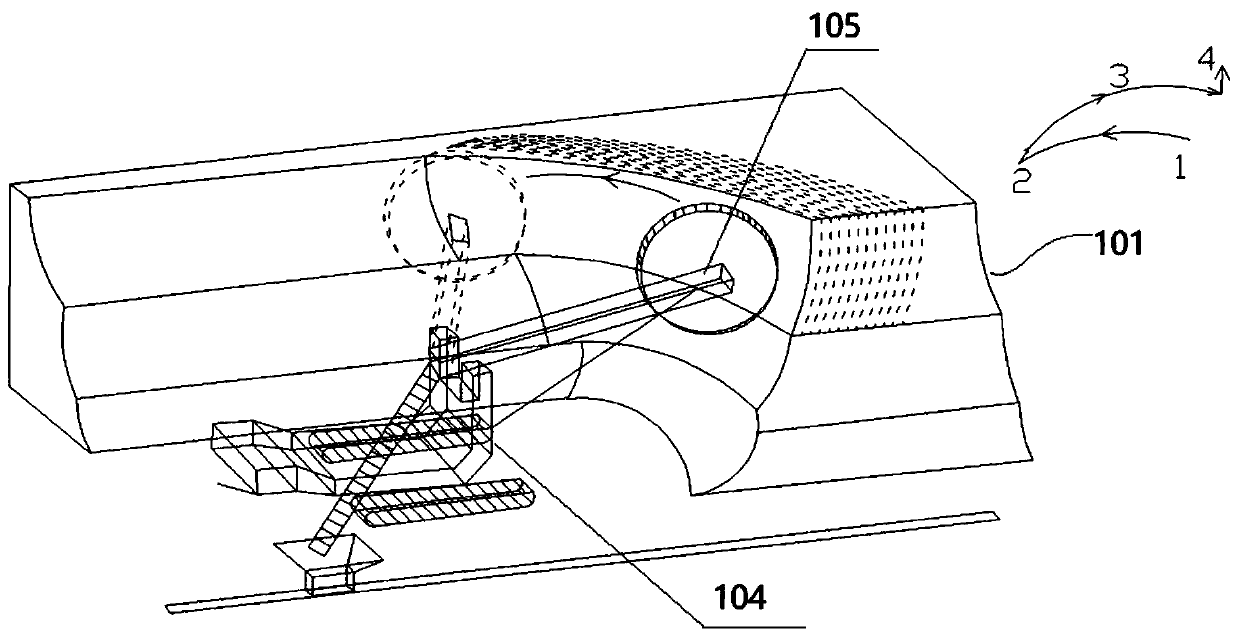

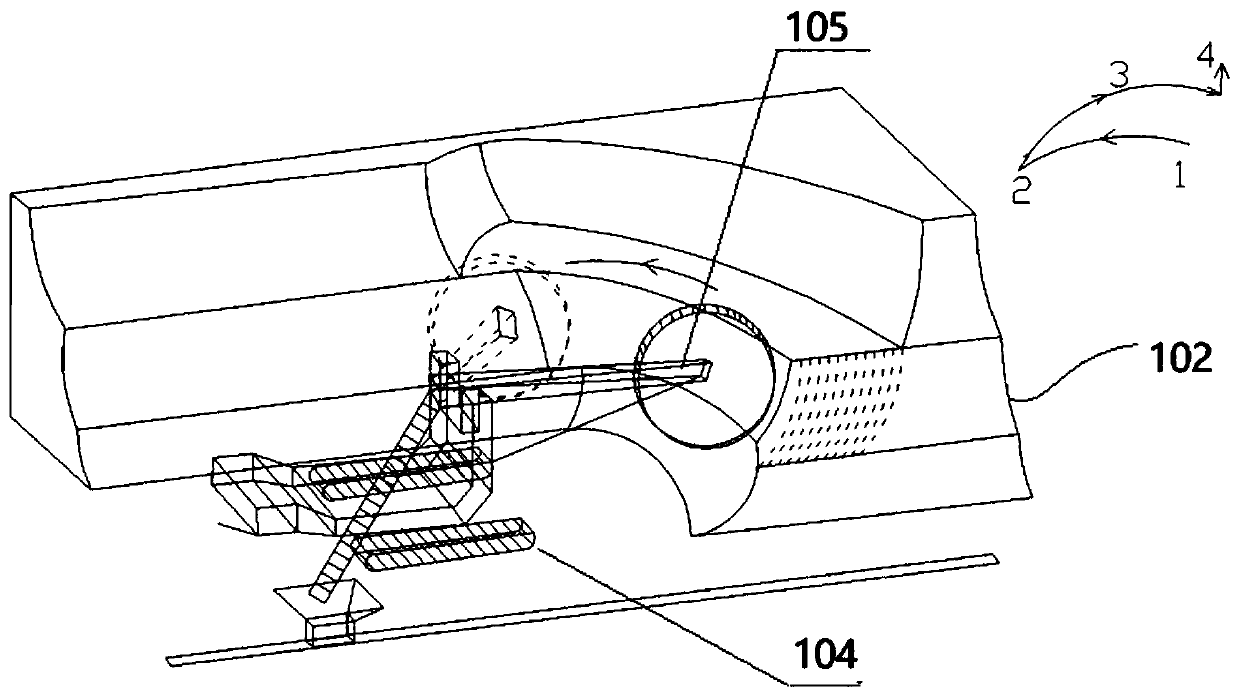

[0019] Such as figure 1 As shown in Fig. 1, when the steps of the open-pit mine have sidewalls, the original steps are damaged, forming a sidewall area 111 (that is, the material on the top slides down to the lower part in a large area), which destroys the original mining step parameters of the bucket wheel excavator, and the material on the top of the steps slips. To the bottom of the slope, the width h of the top of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com