Oil cylinder

A technology for oil cylinders and cylinder blocks, which is applied in the field of oil cylinders that can control the stroke, and can solve the problems of piston rod damage, unfavorable oil sealing, etc., and achieve the effects of preventing impact, simple structure, and compact volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

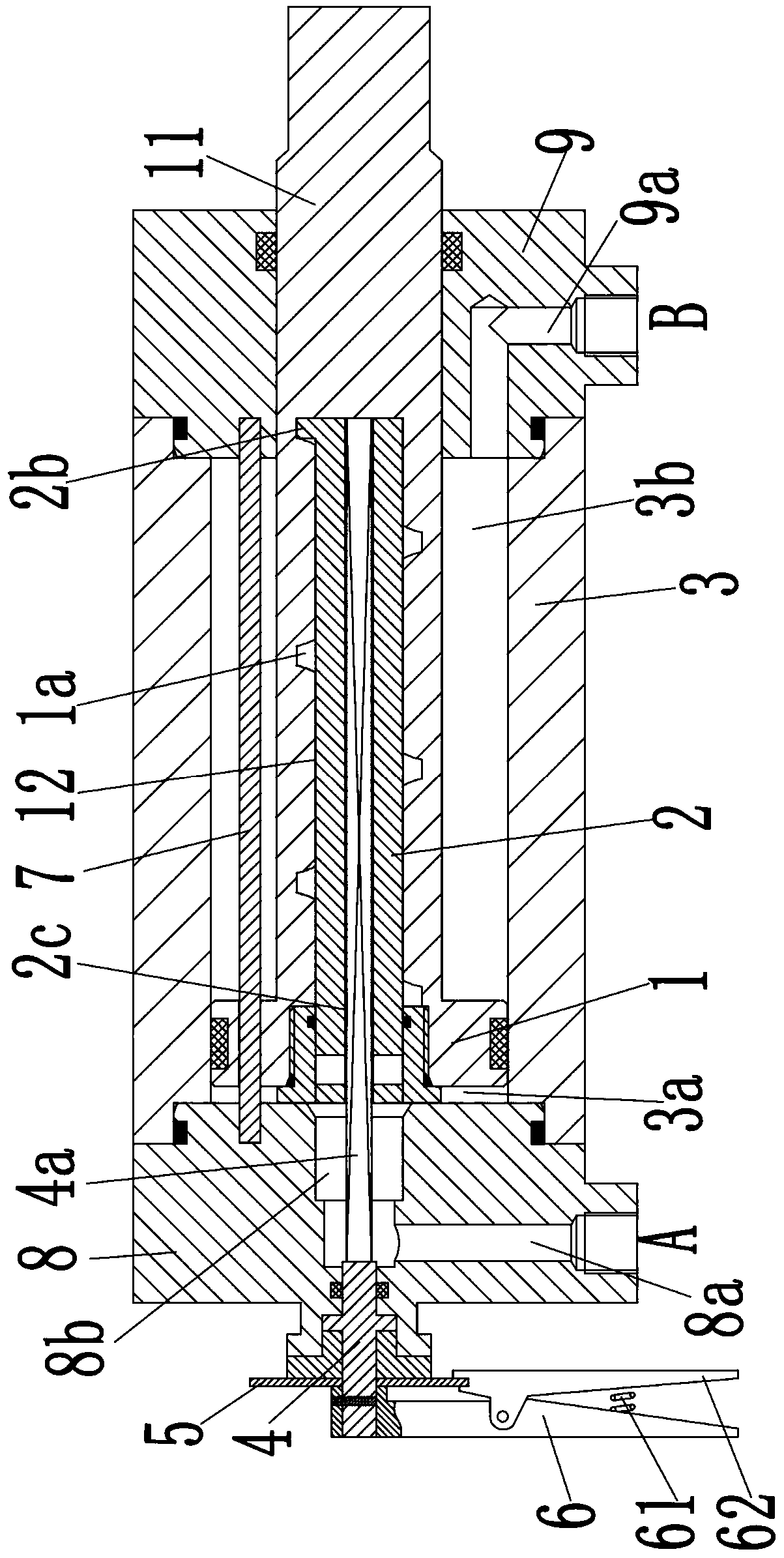

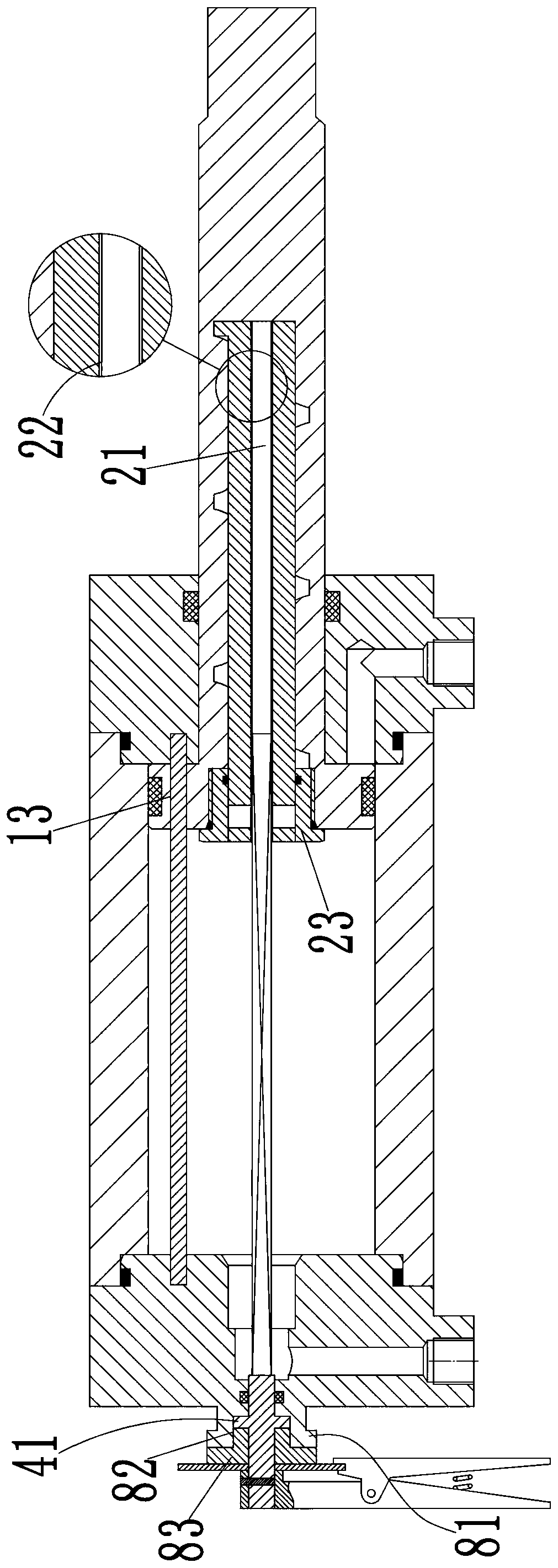

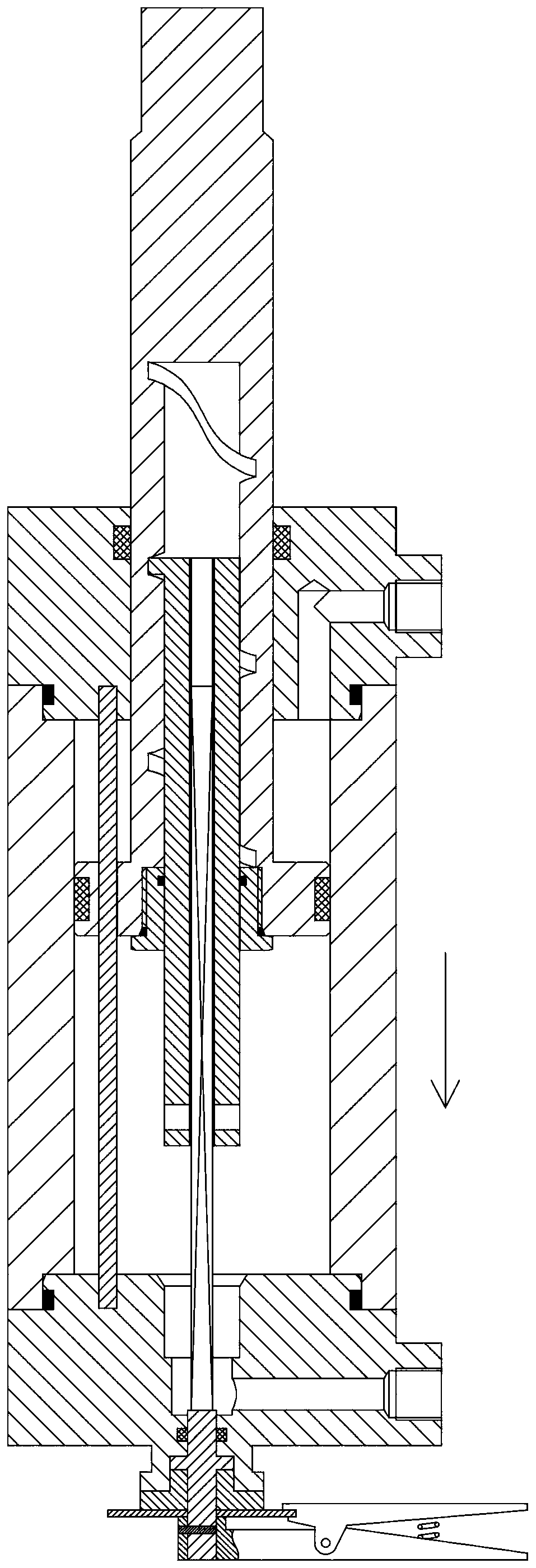

[0020] see Figure 1-4 As shown, an oil cylinder comprises a cylinder body 3, a left end cover 8 is fixedly installed on the left end of the cylinder body 3, a right end cover 9 is fixedly installed on the right end, a piston body 1 is slidably connected in the cylinder body 3, and the piston body 1 The right end of the body 1 is provided with a piston rod 11 protruding from the right end cover 9, a rodless cavity 3a is formed between the piston body 1 and the left end cover 8 in the cylinder body 3, and a rod is formed between the piston body 1 and the right end cover 9. Cavity 3b; the side of the right end cover 9 is provided with a B port, the left end cover 8 is provided with a valve hole 8b on the side facing the piston body 1, and the side of the left end cover 8 is provided with an A port; the left end cover 8 There is a first through hole 8a for connecting port A and valve hole 8b, and the right end cover 9 is provided with a second through hole 9a for connecting port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com