High beam and low beam integrated vehicle headlamp

A technology for far and near beams and headlights, applied in the field of lighting, can solve the problems of reducing service life, reducing the utilization rate of light energy and lighting effect, and limiting the thickness of heat dissipation substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

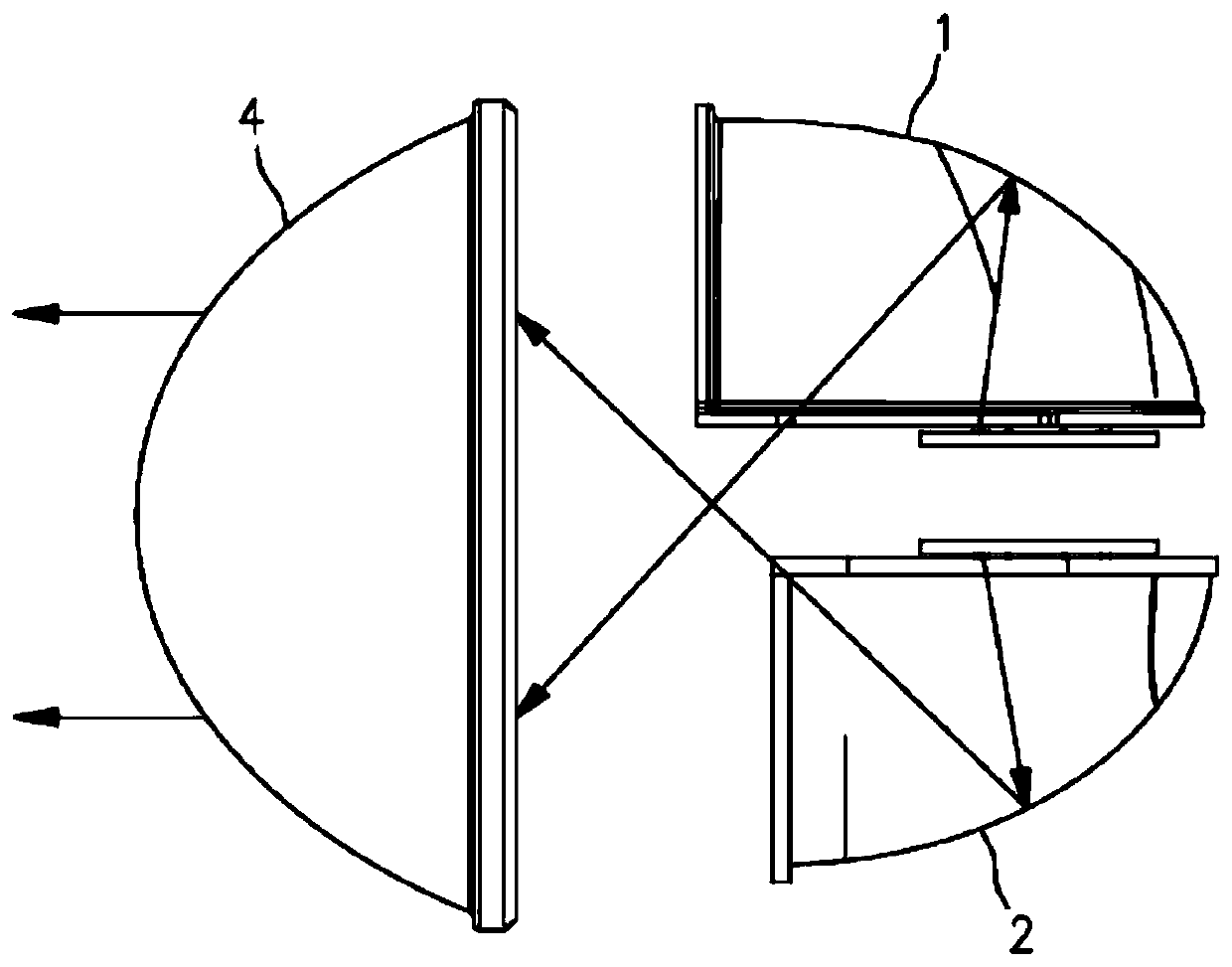

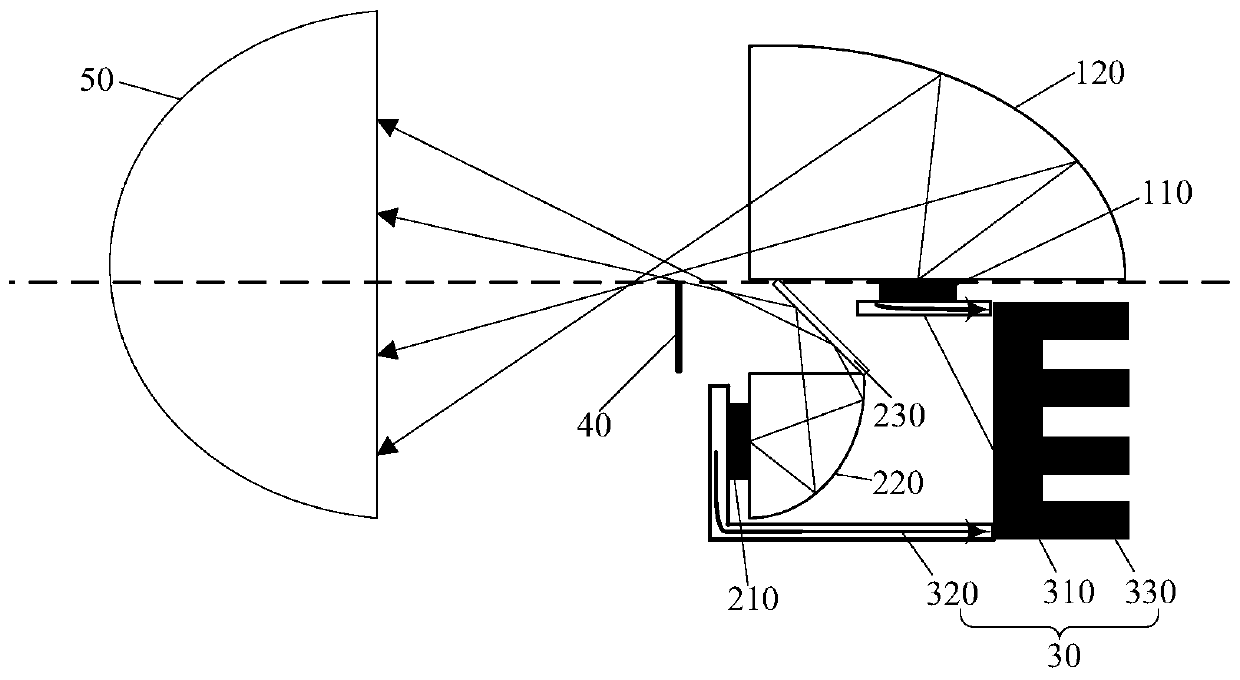

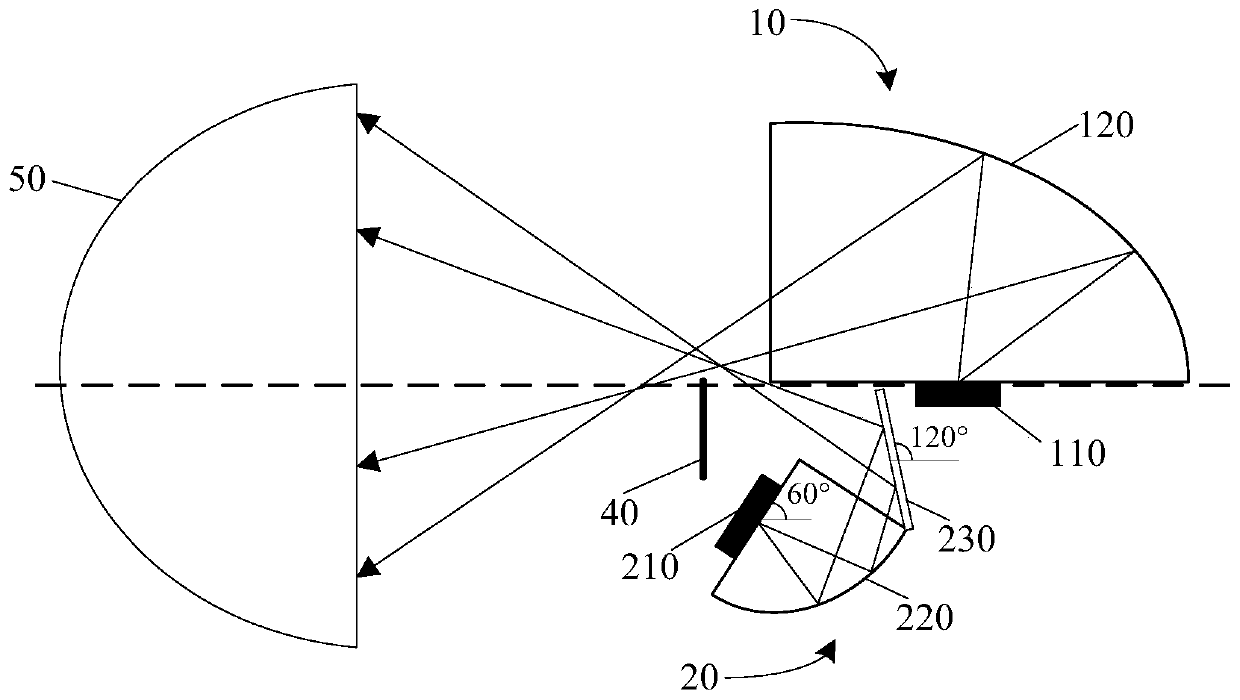

[0023] Such as Figure 2-3 As shown, the present invention provides a vehicle headlamp with integrated far and near beams, including a low beam module 10, a high beam module 20 and a heat dissipation module 30 located below the low beam module 10, and a heat dissipation module 30 located in sequence. The visor 40 and the lens 50 in front of the low beam module 10 and the high beam module 20, the low beam module 10 includes a low beam LED light source 110, and a low beam reflective cup 120 corresponding to the low beam LED light source 110 The high beam module 20 includes a high beam LED light source 210, a high beam reflective cup 220 corresponding to the high beam LED light source 210, and a reflector 230 corresponding to the light outlet of the high beam reflective cup 220, the The height of the top of the reflector 230 corresponds to the height of the light-emitting surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com