Bamboo forest directional cultivation method aiming at utilization of raw bamboo materials of tea poles

A cultivation method, the technology of tea stem bamboo, which is applied in the field of directional cultivation of bamboo for the utilization of tea stem bamboo raw bamboo, can solve the problems of unsustainable development, low output of raw bamboo felling, failure to meet market demand and economic benefits, etc., to achieve Meet the needs of industrial development, increase output, and achieve high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: The original bamboo material of Ligong Village, Gushui Town, Guangning County, Guangdong Province is used for directional cultivation of tea stalk bamboo forest base area of 50 mu. In the spring of 2014, there were 39131 original bamboos / ha in the tea stalk bamboo forest, and the average diameter of the bamboo forest was 2.6cm; The bamboo forest was regulated, and 8,241 bamboos / ha were selectively cut in that year, including 5,055 5-year-old bamboos in full cutting, 1,604 4-year-old bamboos in thinning, 1,582 3-year-old bamboos in thinning, and 1-year-old and 2-year-old bamboos were not selectively cut , so that the bamboo plants in the tea pole bamboo forest are controlled at 30,890 plants / ha and the distribution is uniform, and the average diameter at breast height is controlled at 1.94 cm; the bamboo plants are pulled out and leaves 5-8 plates to increase the height of the branches, and improve the self-fertilization effect of the bamboo forest. Increase ...

Embodiment 2

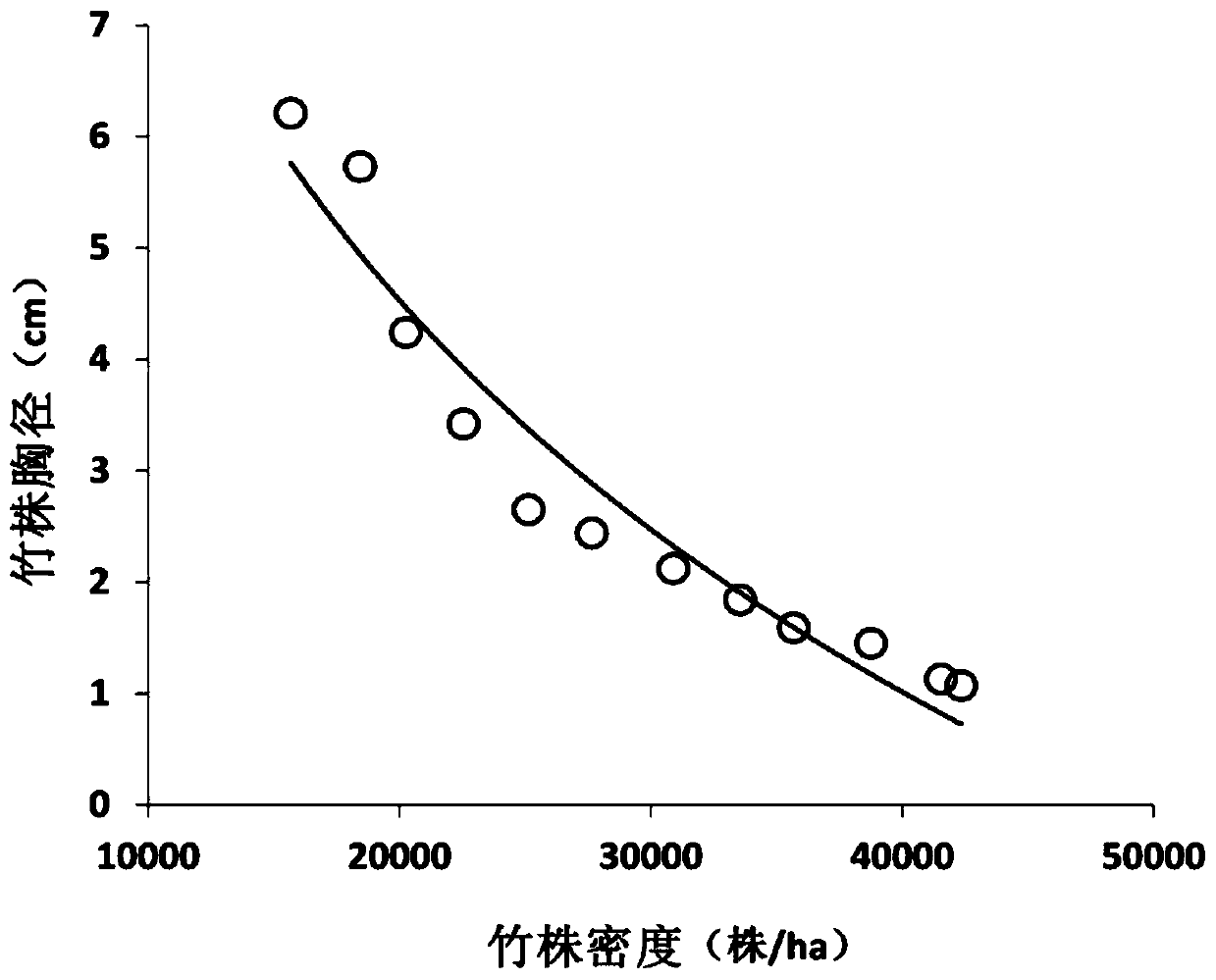

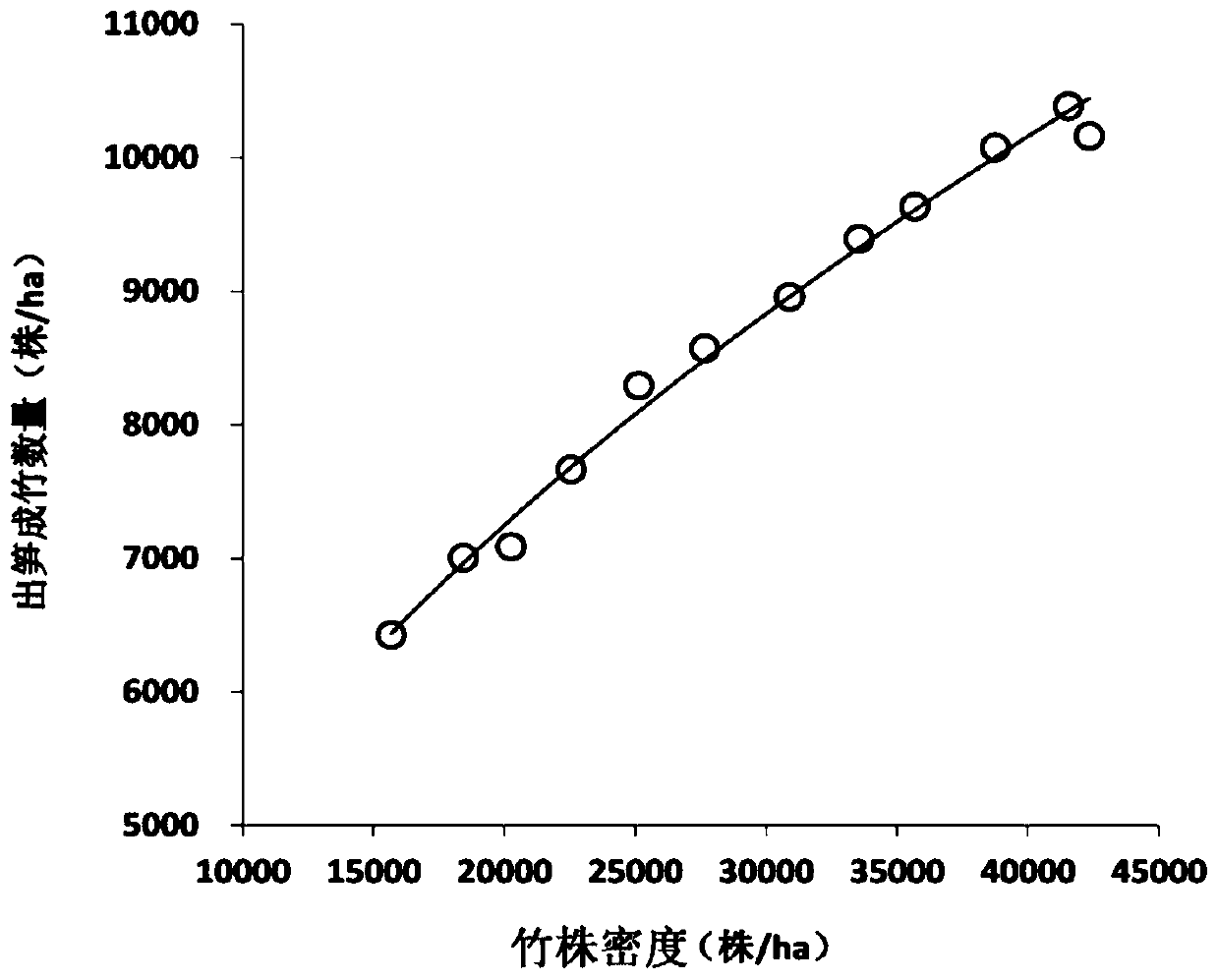

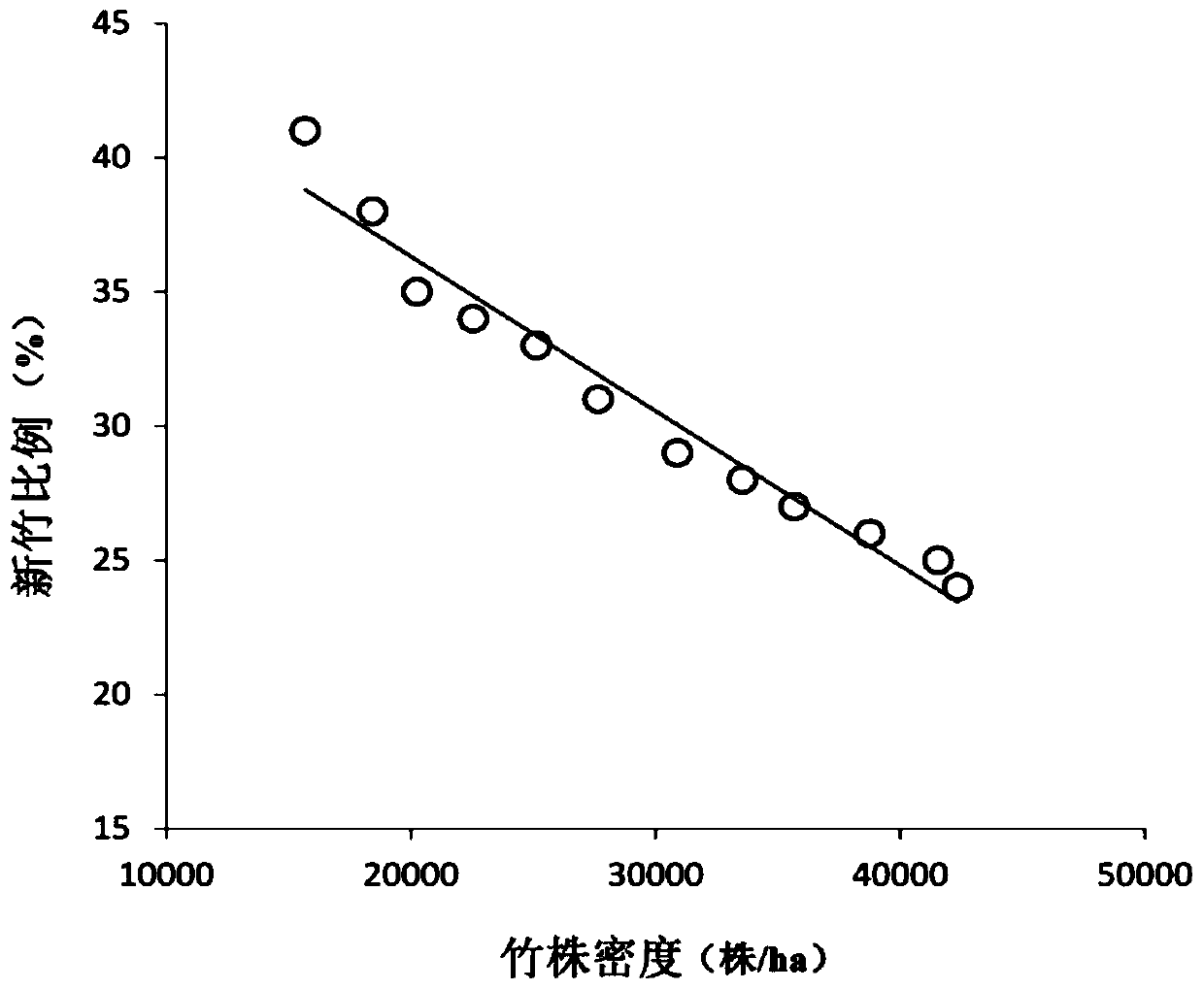

[0027] Example 2: The original bamboo in Ligong Village, Gushui Town, Guangning County, Guangdong Province utilizes directional cultivation of tea stalk bamboo forest base area of 50 mu. In the spring of 2014, there were 39,332 original bamboos / ha in the tea stalk bamboo forest, and the average diameter of the bamboo forest was 2.6cm; In the bamboo forest, 8,541 bamboos / ha were selectively cut in the year, including 7,443 5-year-old bamboos, 659 4-year-old bamboos, 439 3-year-old bamboos, and 1-year-old and 2-year-old bamboos. , so that the bamboo plants in the tea pole bamboo forest are controlled at 30,789 plants / ha and the distribution is even, such as figure 1 As shown, the relationship between bamboo plant density and bamboo plant DBH was controlled by fitting the logarithmic equation model, and reached a very significant level (R 2 =0.93, P2 is the coefficient of determination, and P is the probability. According to statistics, a data model is established. The larger t...

Embodiment 3

[0028] Example 3: The original bamboo material of Ligong Village, Gushui Town, Guangning County, Guangdong Province is used for directional cultivation of tea stalk bamboo forest. The base area is 50 mu. The bamboo forest was regulated, and 8,423 bamboos / ha were selectively cut in that year, including 6,975 5-year-old bamboos, 869 4-year-old bamboos, and 579 3-year-old bamboos, and no selective cutting of 1-year-old and 2-year-old bamboos , so that the bamboo plants of the tea pole bamboo forest are controlled at 30,945 plants / ha and evenly distributed. In the present embodiment, the average DBH is controlled at 2.1 cm, and the average DBH calculated according to the logarithmic equation model is at 2.34 cm, so this parameter Belong to the comparative test parameter of embodiment 2; To bamboo plant, carry out branching and beating leaves 5-8 discs to make its branch height increase, improve the self-fertilization effect of bamboo forest, increase gaps to promote bamboo shoot ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com