Flying rod sheet fixing seat, flying rod sheet fixing structure and cavity filter

A fixed structure and fixed seat technology, applied in the field of communication, can solve problems such as shaking, installation difficulties, poor indicators, etc., and achieve the effect of enhancing the stability of the combination and ensuring the reliability of work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in combination with the embodiments and accompanying drawings.

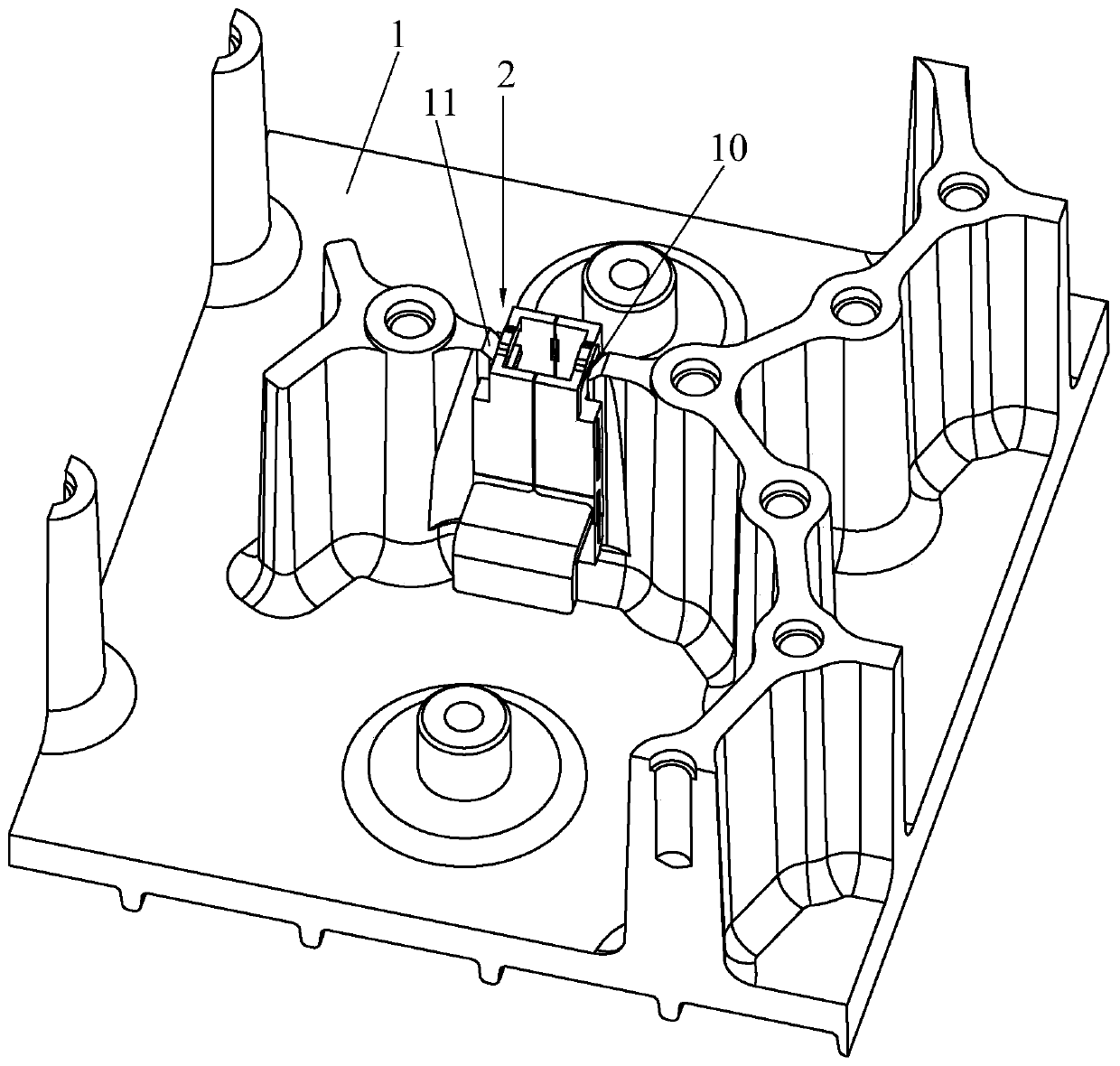

[0022] see figure 1 and figure 2 , the present invention discloses a cavity filter, comprising a filter cavity 1 and a fly rod fixing structure 2, a mounting position 10 is formed in the filter cavity 1, and two mounting ribs 11 are formed on both sides of the mounting position 10 , the flying rod sheet fixing structure 2 is vertically installed at the installation position 10 and is clamped and matched with the two installation ribs 11 through the vertical slide grooves 40 on the front and rear sides thereof to realize a stable installation.

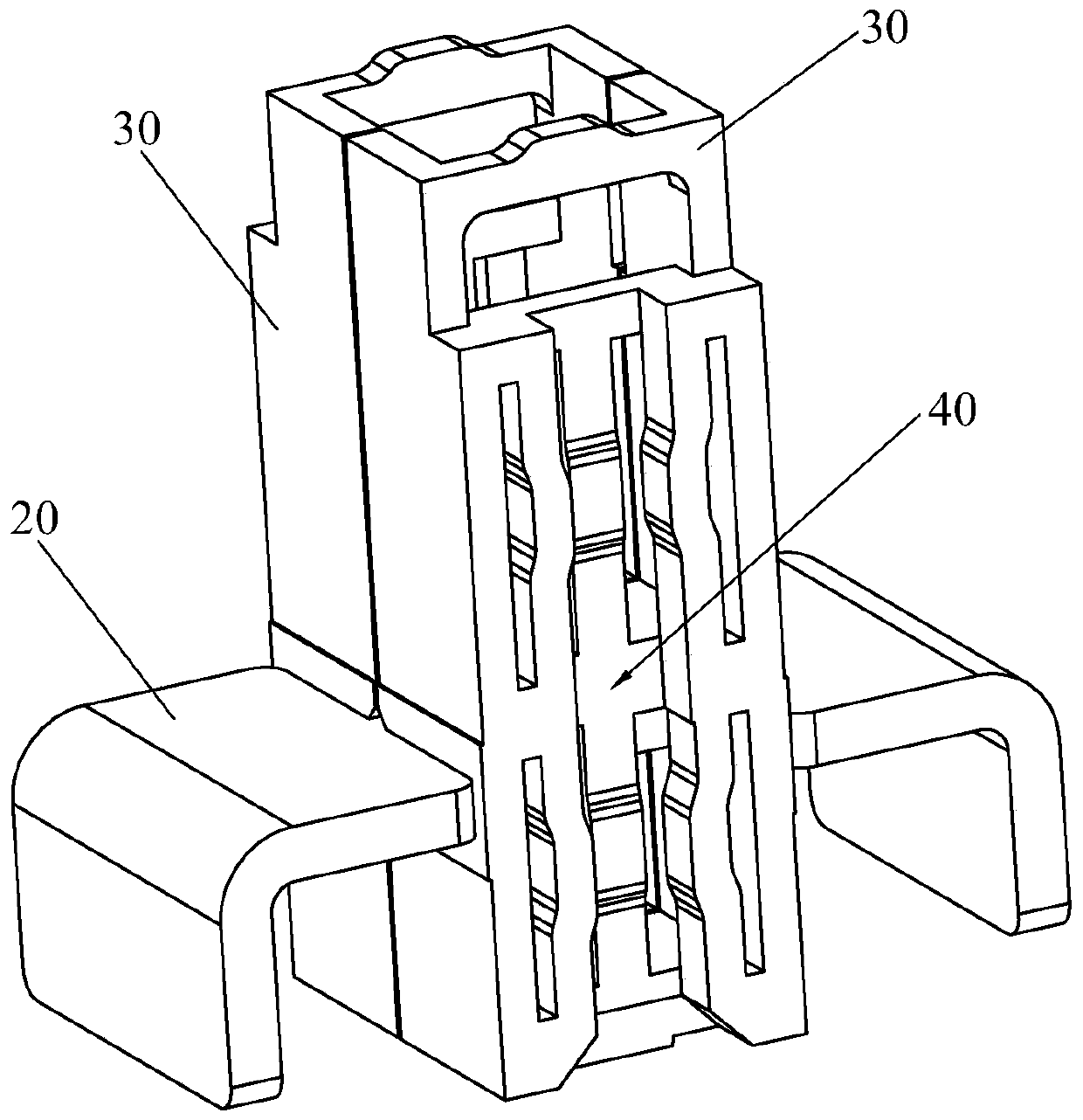

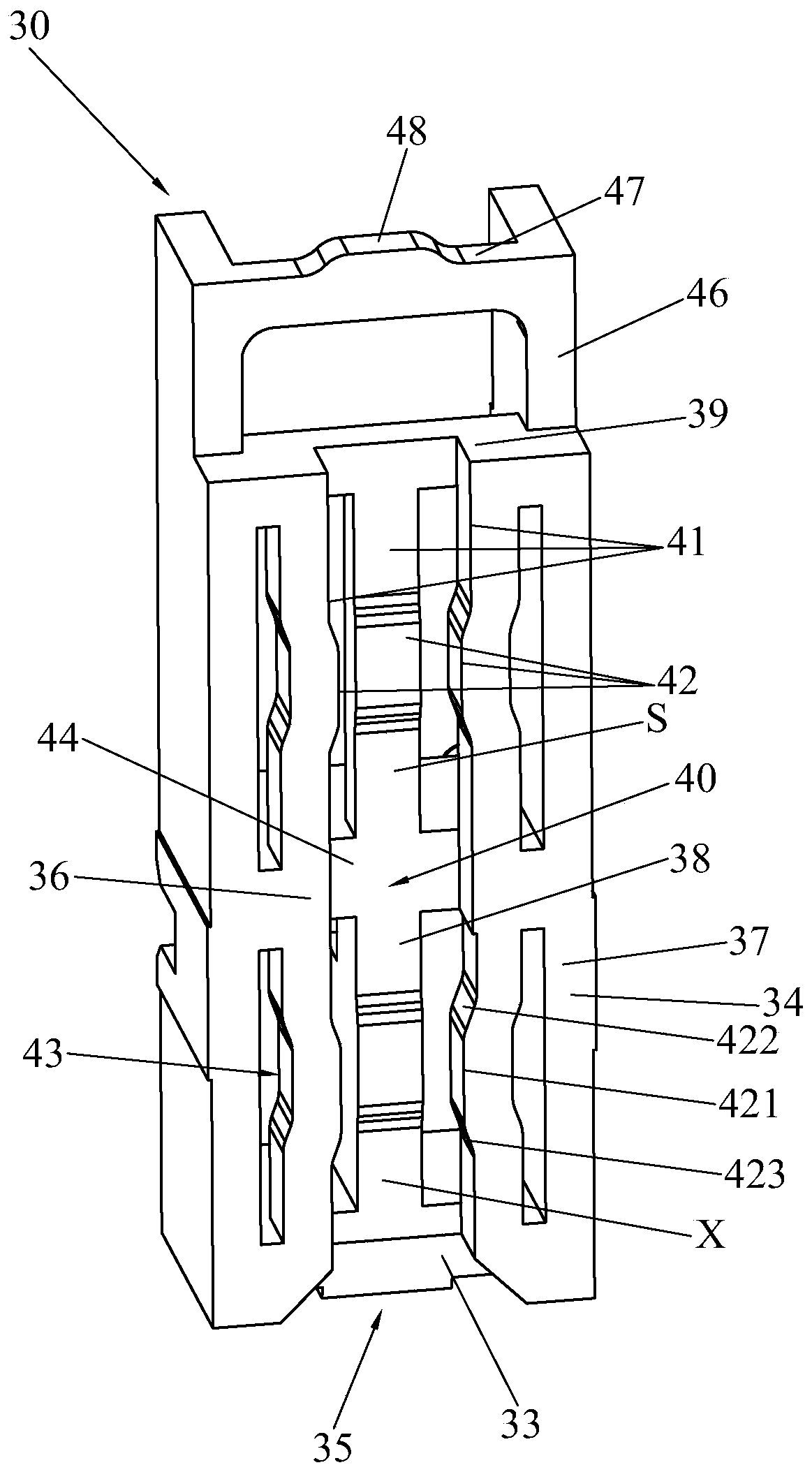

[0023] see Figure 2 to Figure 4 The flying rod sheet fixing structure 2 includes a flying rod sheet 20 and two flying rod sheet fixing seats 30, the rear sides of the two flying rod sheet fixing seats 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com