Glazing unit, in particular for aeronautics, able to be blocked in its receiving opening in the event of breakage

A technology for accommodating openings and window glass, applied in the direction of glass/slag layered products, aircraft accessories, layered products, etc., can solve problems such as decompression window glass, window glass structure detachment, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

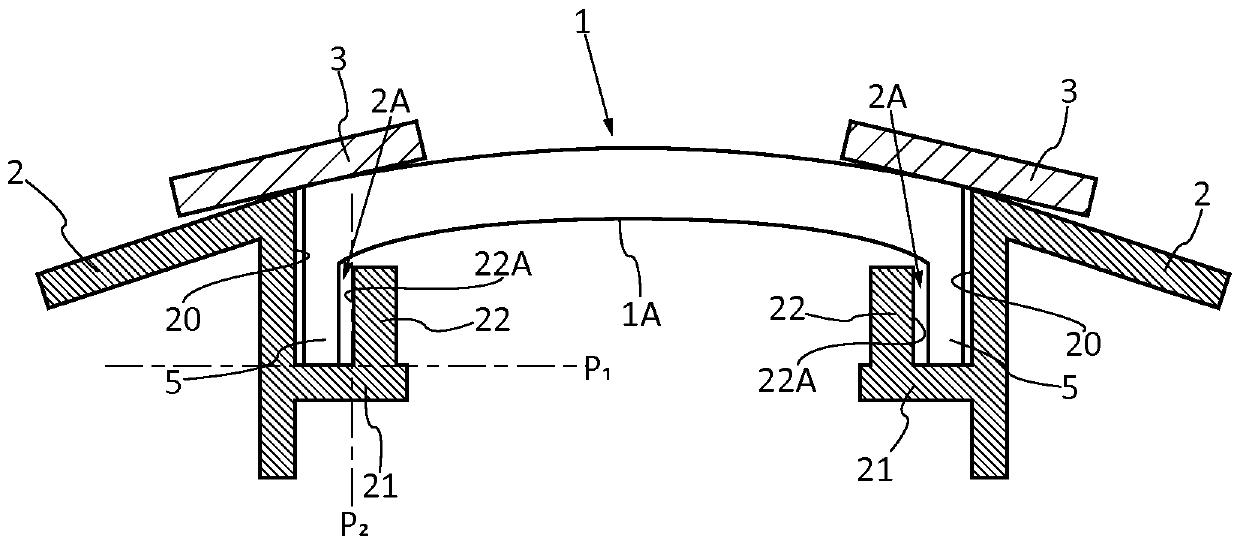

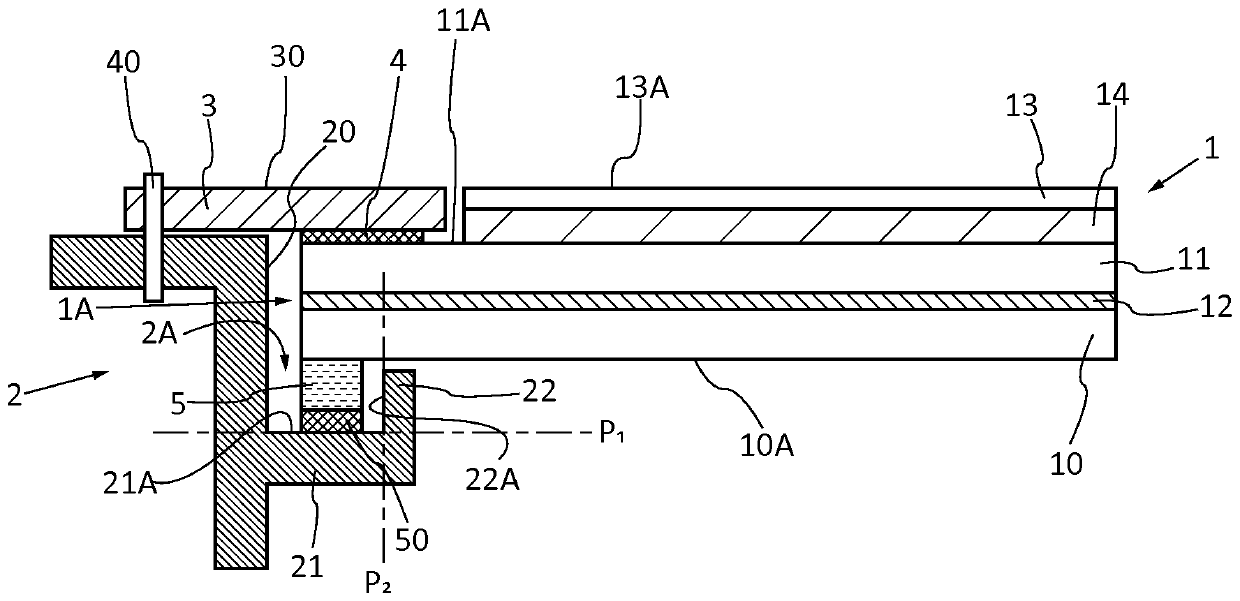

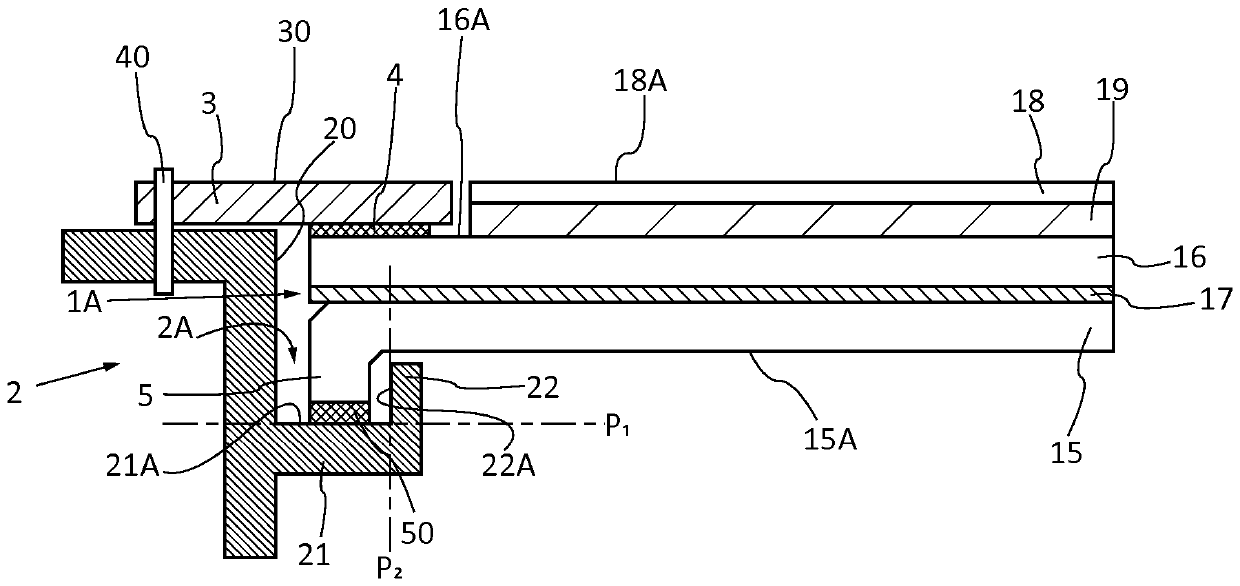

[0040] Figure 1 to Figure 3 The shown glazing 1 according to the invention is intended to be accommodated in the fuselage / structure 2 of an aircraft.

[0041] In known manner, the glazing 1 comprises at least one layer, preferably multiple layers arranged as a laminate.

[0042] exist figure 1 In the example of a glazing, the glazing 1 comprises three layers, the first layer corresponds to a first substrate 10 made of glass, the first substrate is preferably strengthened (thermally strengthened or chemically strengthened) glass typically 8 mm thick, The second layer consists of a second substrate 11, likewise made of glass, preferably reinforced and typically 8 mm thick, the two glass substrates 10 and 11 being fixed to each other by an interlayer 12 of PVB type , and the third layer consists of a third glass substrate 13, usually 3 mm thick, and an intermediate sheet 14, usually 6 mm thick, made of a plastic material such as PU, which connects the second glass substrate 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com