Magnetoelectric composite gas purification method

A gas purification and composite technology, which is applied in the field of gas purification system and magnetoelectric composite gas purification, can solve the problems of reducing dust removal efficiency and increasing the power consumption of electrostatic dust removal devices, so as to improve collection efficiency, improve utilization rate, and enhance deflection. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

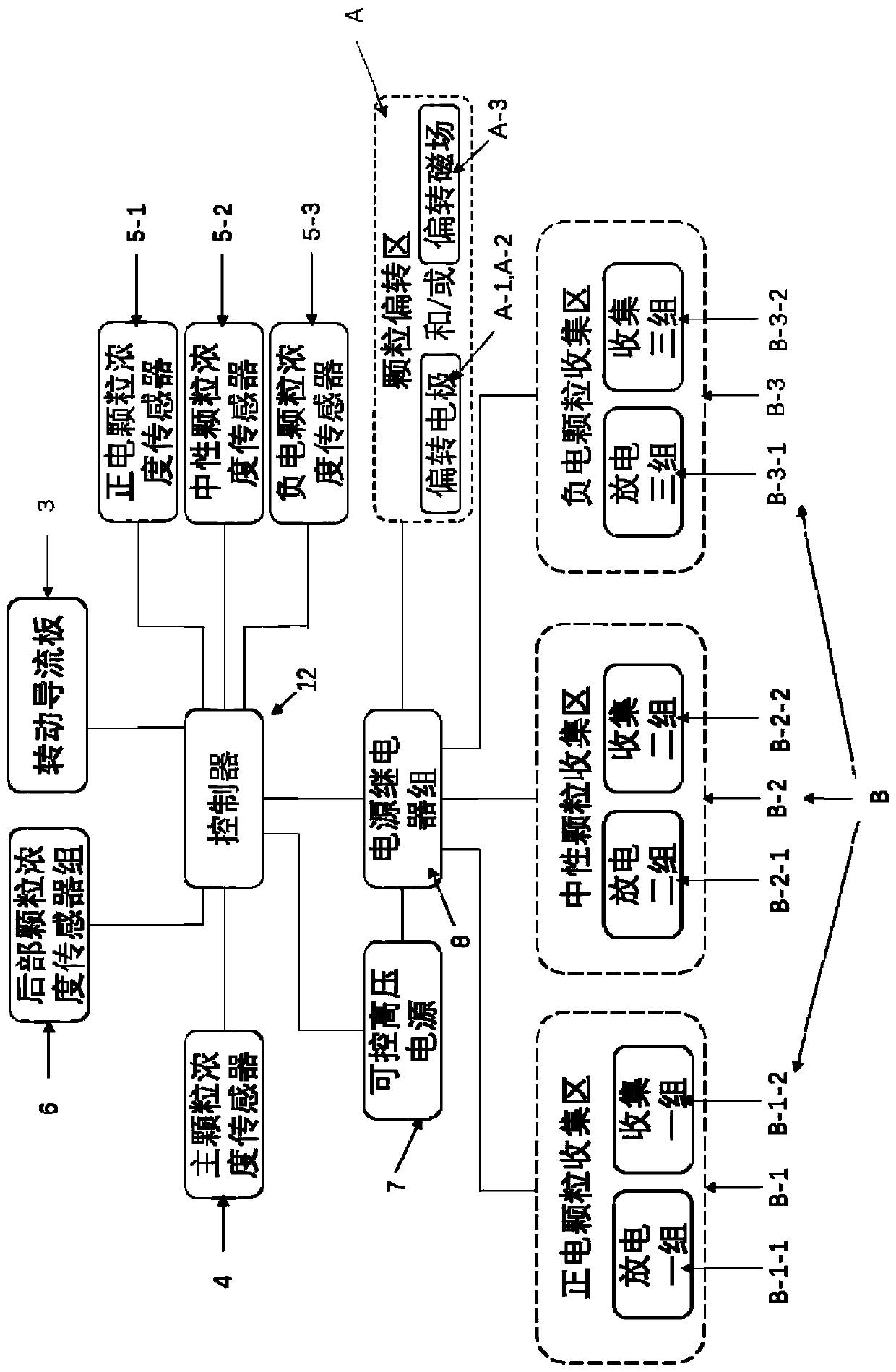

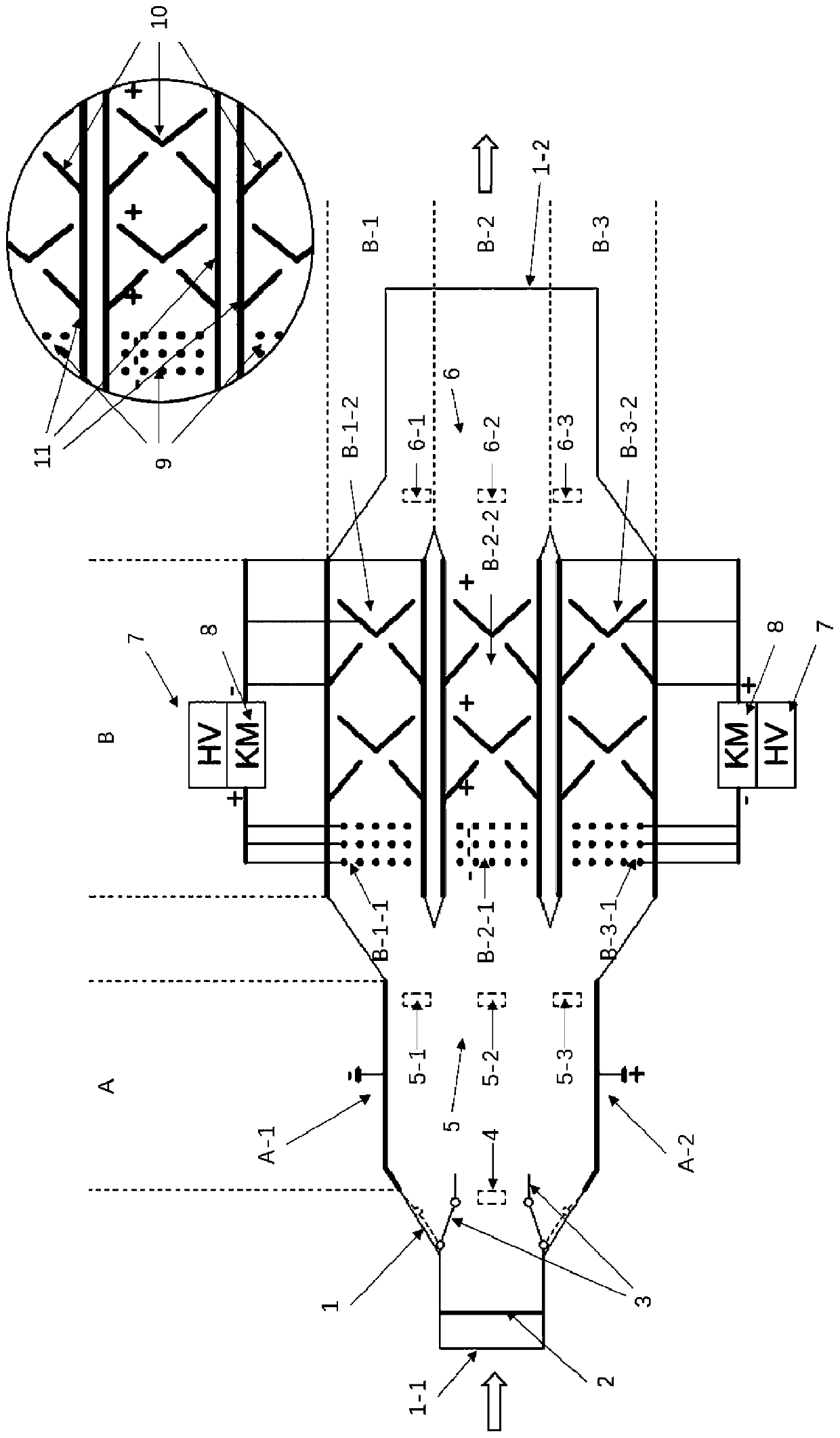

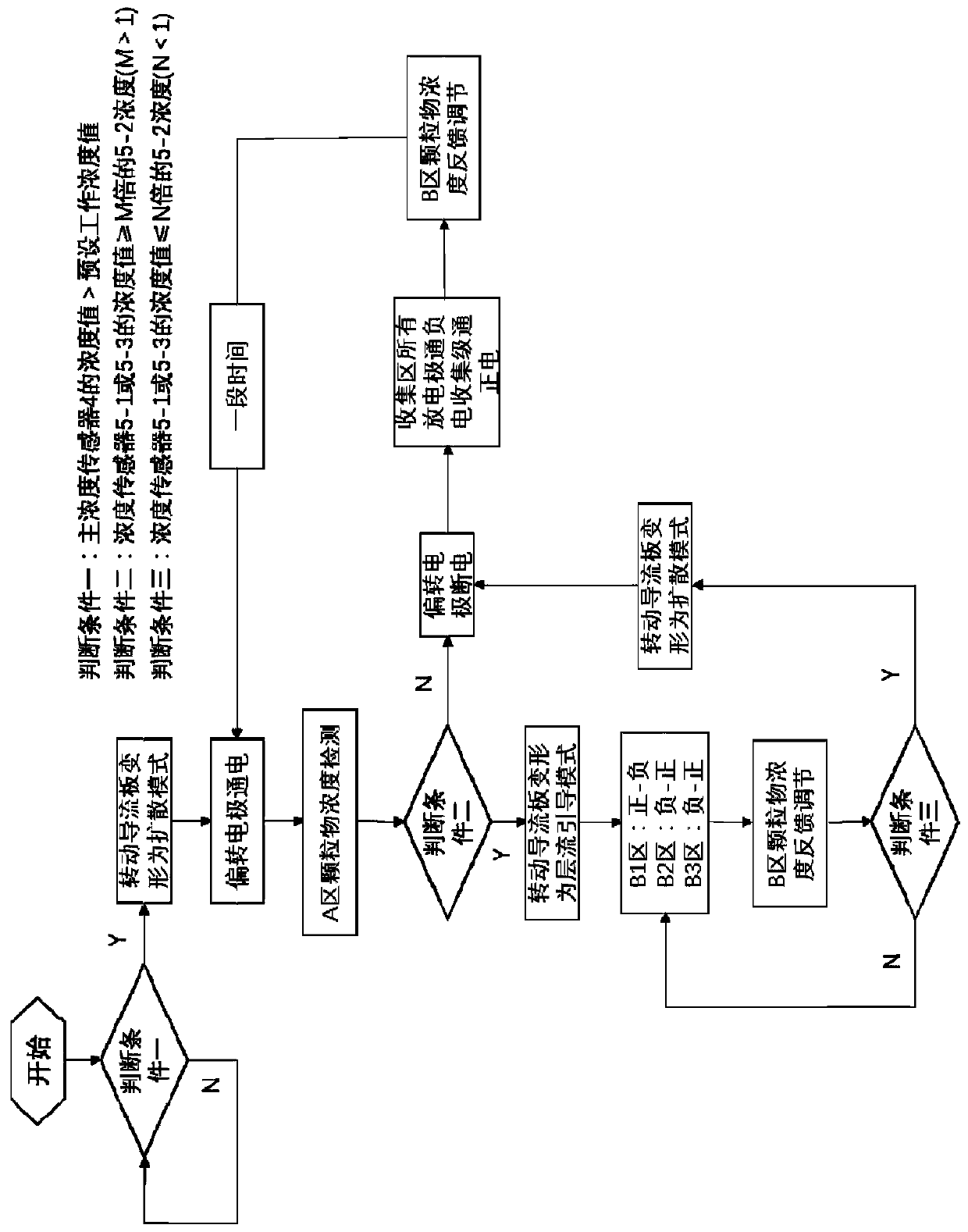

[0032] as attached figure 1 , 2 The shown intelligent gas purification system includes an electrostatic precipitator, the device has a housing 1, and the device includes an air inlet channel 1-1, a particle deflection area A, a particle collection area B and an air outlet channel 1-2; The air flow passes through the air intake channel 1-1, the particle deflection area A, the particle collection area B and the air outlet channel 1-2 in sequence; the air intake channel 1-1 is provided with a flow equalizer 2 for homogenizing the incoming air flow into layers The passage at the rear of the air intake channel 1-1 is a trumpet-shaped opening, which is connected with the shell of the particle deflection area A; a pair of rotating deflectors 3 are arranged at the rear of the air intake channel 1-1, and the rotating deflectors 3 can Electric hinges are used to realize the rotation, and there are two modes of laminar flow guidance and diffusion. In the laminar flow guidance mode, the ...

Embodiment 2

[0046] Reference attached figure 1 , 6 , the deflection negative electrode A-1 and the deflection positive electrode A-2 in the particle deflection area A of the electrostatic precipitator of embodiment one are removed, and the deflection magnetic field A-3 is added in the particle deflection area A, and the magnetic field of the deflection magnetic field A-3 The direction of the induction line is perpendicular to the direction of the air flow, and the principle that the charged particles are subjected to the Lorentz force of the magnetic field when moving perpendicular to the magnetic field, the deflection magnetic field A-3 realizes the same effect as that of the deflection electrodes A-1 and A-2 in the first embodiment. The function is to deflect the positively charged particles in the airflow into the positively charged particle collection area B-1, and make the negatively charged particles in the airflow deflect into the negatively charged particle collection area B-3.

...

Embodiment 3

[0050] Reference attached figure 1 , 7 , adding a deflection magnetic field A-3 to the particle deflection area A of the electrostatic precipitator in Embodiment 1, the direction of the magnetic field line of the deflection magnetic field A-3 is perpendicular to the airflow direction, and the charged particles are subjected to the magnetic field Loren when moving in a perpendicular to the magnetic field The principle of Zi force action, the deflection magnetic field A-3 and the deflection electrodes A-1 and A-2 work together, that is, the positively charged particles in the airflow are deflected into the positively charged particle collection area through the joint action of the electric field force and the Lorentz force B-1, deflecting the negatively charged particles in the gas flow into the negatively charged particle collection zone B-3. The advantage of using electric field and magnetic field superposition is that it can obtain a better deflection effect than using a sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com