Orbital spraying robot

A spraying robot and orbital technology, applied in manipulators, spraying devices, manufacturing tools, etc., can solve problems such as production accidents and occupational diseases, inability to enter the segmented inner cabin through manholes, and limited spraying range, saving initial cost investment. , Easy to quickly arrange and move, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

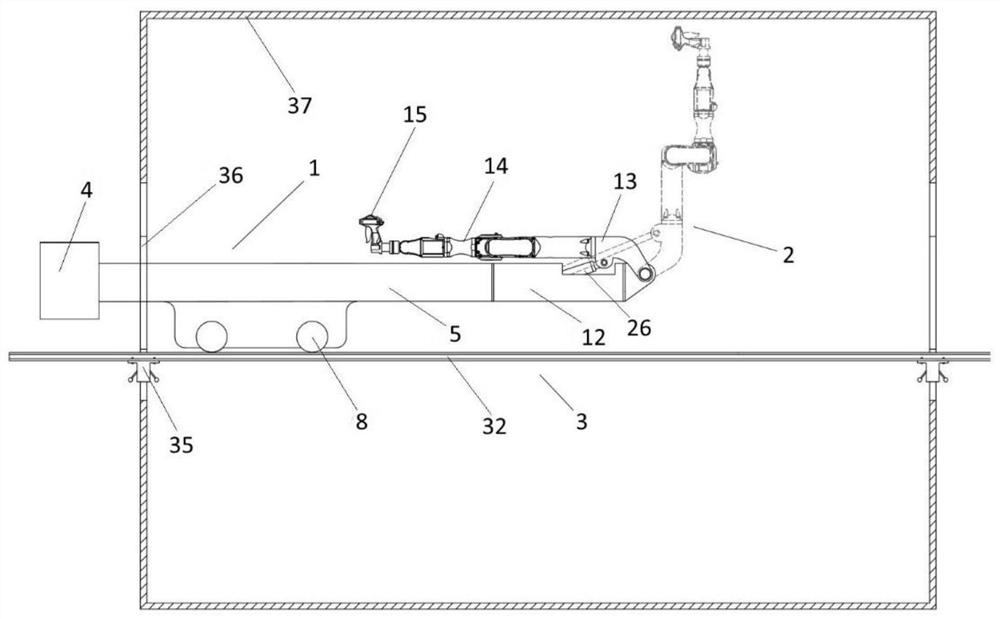

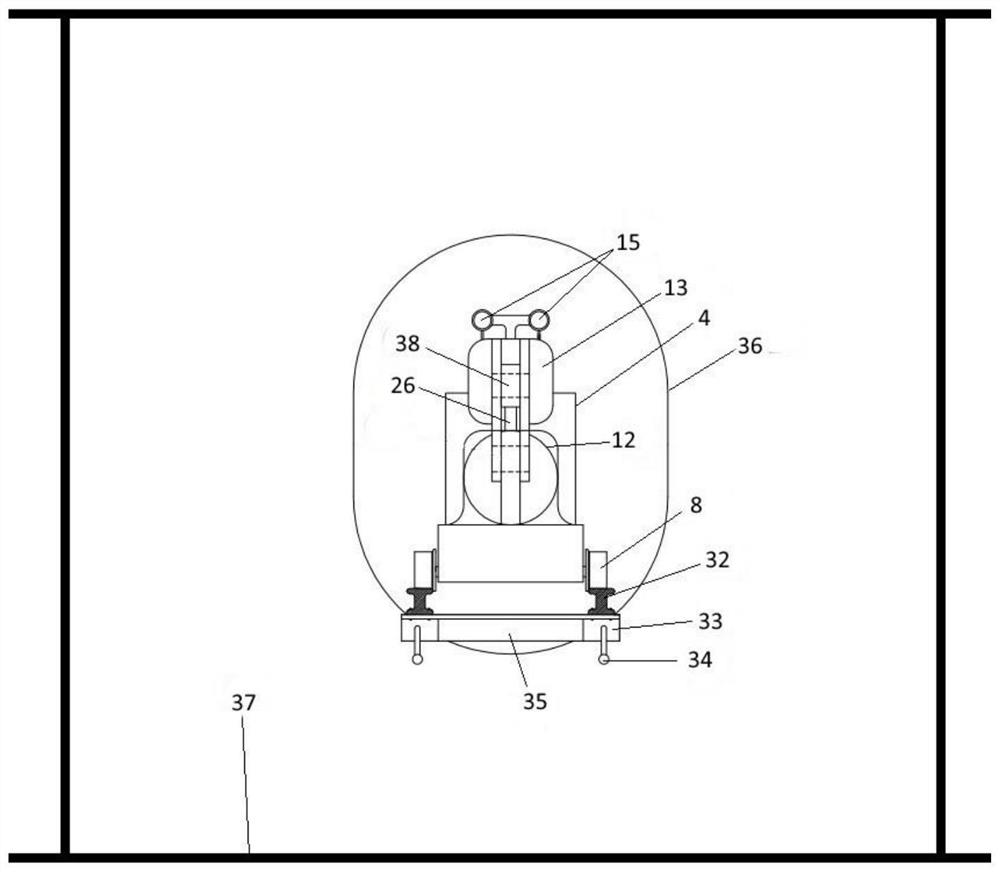

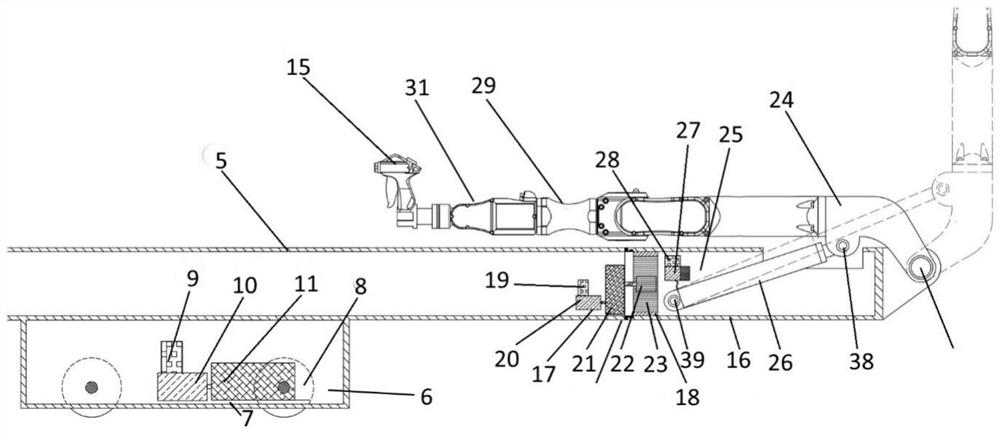

[0030] Such as Figure 1-3 As shown, it is a rail-type spraying robot related to this embodiment, which includes: a rail car 1, a rotary folding mechanical arm 2 and a slide rail device 3, wherein: the rail car 1 is arranged on the slide rail device 3 and is connected with the slide rail The device 3 is movably connected, and the rotating and folding mechanical arm 2 is arranged at one end of the rail car 1 .

[0031] The rail car 1 includes: a counterweight 4, a vehicle frame 5 and a traveling mechanism 6, the cross section of the counterweight 4 is rectangular, wherein: the counterweight 4 is arranged on the vehicle frame 5 opposite to the rotary folding mechanical arm 2 At the other end, the traveling mechanism 6 is arranged at the bottom of the vehicle frame 5 and drives the vehicle frame 5 to move on the track 32 .

[0032] The traveling mechanism 6 includes: a driving mechanism 7 and rubber wheels 8 , wherein: the rubber wheels 8 are arranged on the bottom of the vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com