Aluminum powder protecting method

A technology of aluminum powder and protective agent, applied in the field of materials, can solve problems such as performance reduction and activity reduction, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

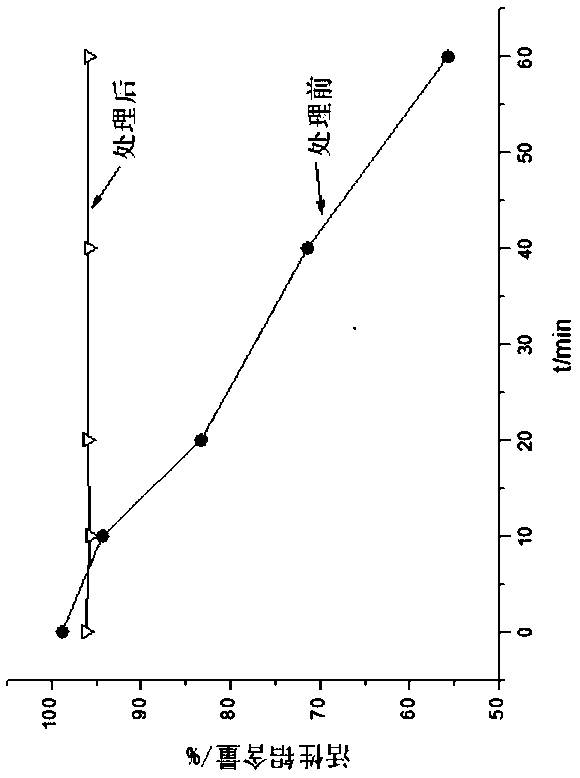

Image

Examples

Embodiment 1

[0034] (1) Weigh aluminum powder and protective agent (in this example, paraffin wax is used as protective agent), the mass ratio of aluminum powder and protective agent is 98:2, and set aside.

[0035] (2) Add the protective agent into the second solution (the second solution uses alkanes) at 70-80°C with stirring, and fully dissolve the protective agent in the second solution to obtain the second intermediate.

[0036] (3) Mix and stir the aluminum powder and the first solution (the first solution uses alkane) at 70-80°C to obtain the first intermediate, and continue to stir the first intermediate.

[0037] (4) Add the second intermediate dropwise into the first intermediate at 70-80°C under stirring conditions. After the second intermediate is added dropwise, continue to stir the solution for 2-6 hours until the protective agent and aluminum powder are completely coated to obtain the third intermediate without delamination.

[0038] (5) Dynamically drying the third interme...

Embodiment 2

[0041] (1) Weigh aluminum powder and protective agent (in this example, titanate coupling agent is used as protective agent), the mass ratio of aluminum powder and protective agent is 99:1, and set aside.

[0042] (2) Add the protective agent into the second solution (the second solution uses ethyl acetate) under stirring at 60-70°C, and fully dissolve the protective agent in the second solution to obtain the second intermediate.

[0043] (3) Mix and stir the aluminum powder and the first solution (the first solution uses alkane) at 60-70°C to obtain the first intermediate, and continue to stir the first intermediate.

[0044] (4) Add the second intermediate dropwise into the first intermediate at 70-80°C under stirring conditions. After the dropwise addition of the second intermediate was completed, the solution was continued to be stirred for 5 hours until the protective agent and the aluminum powder were completely coated to obtain the third intermediate without delaminatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com