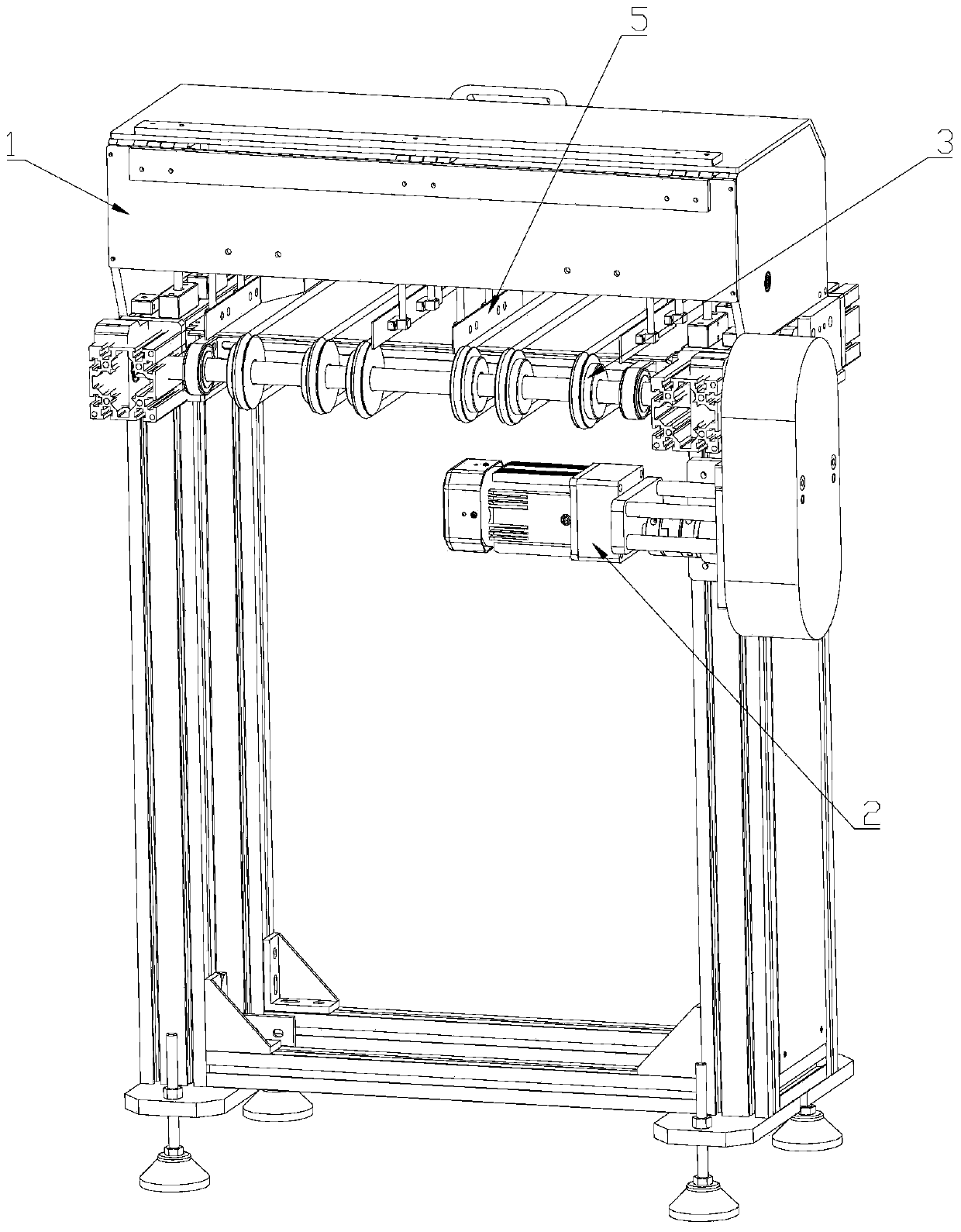

Splitting device

A material-distributing device and material-distributing mechanism technology, used in transportation and packaging, conveyors, container manufacturing machinery, etc., can solve problems such as poor stability, inability to change the direction of packaging bags, derailment of conveyor belts, etc., and achieve improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

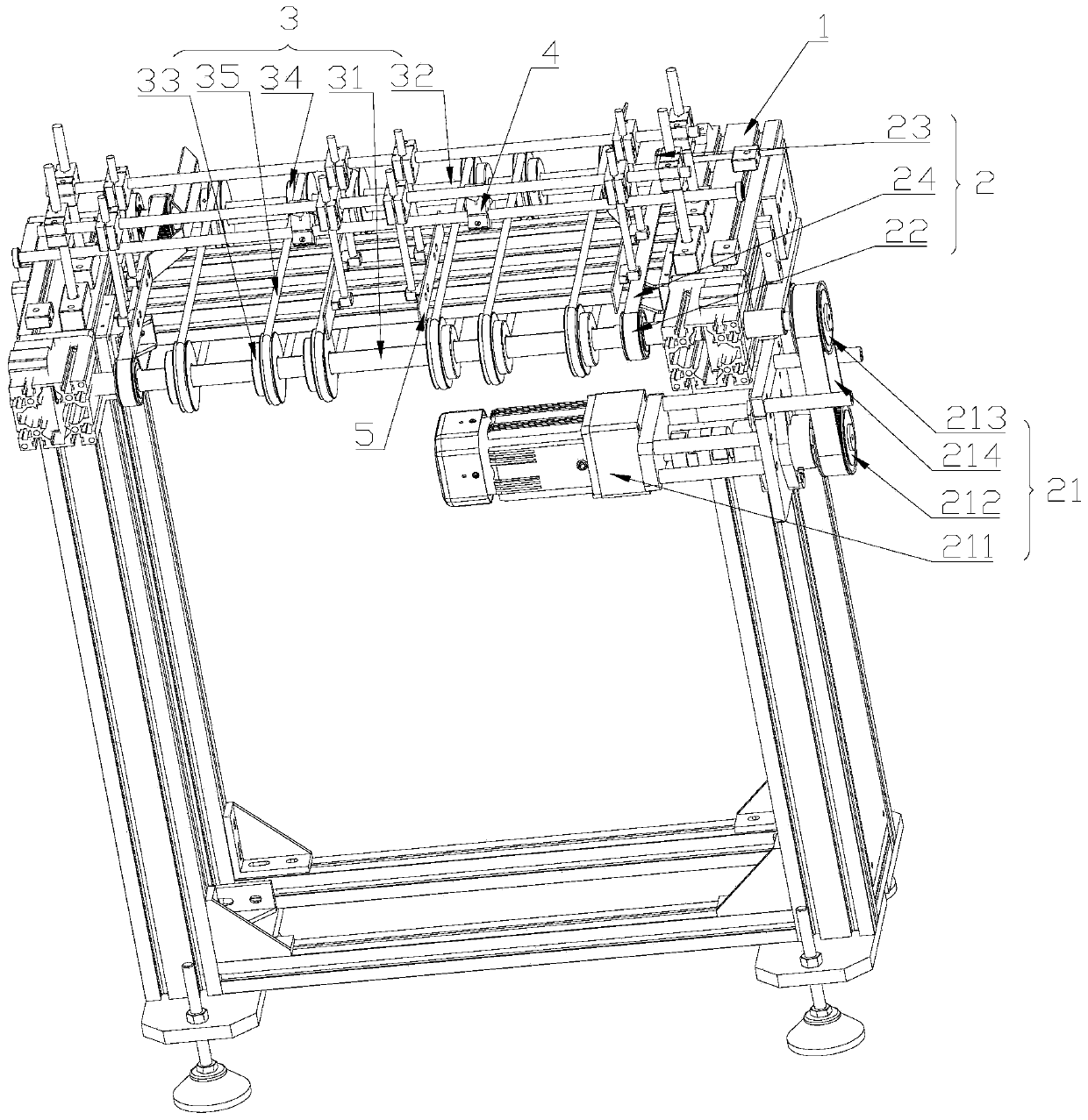

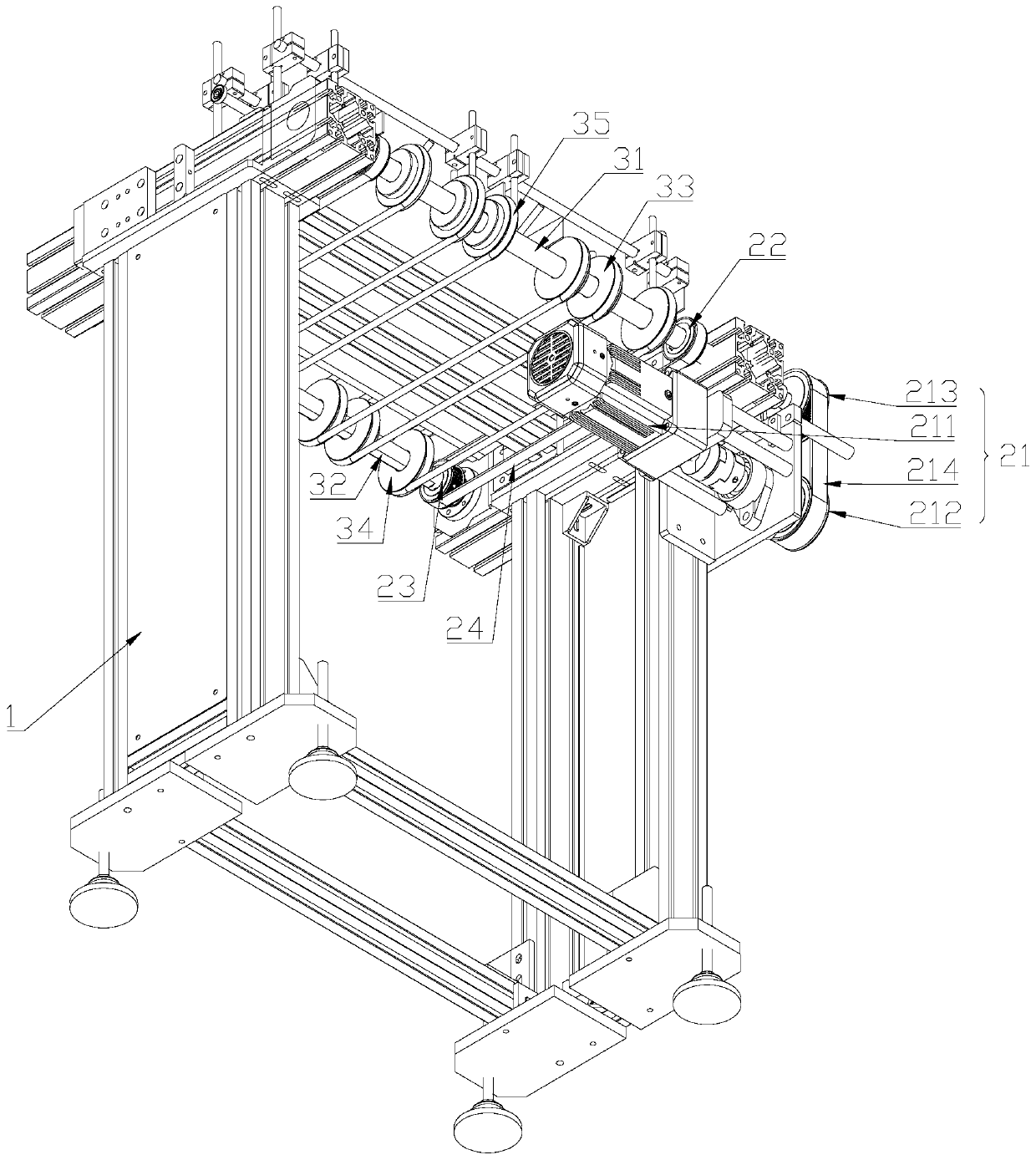

[0051] Furthermore, please also refer to figure 2 and image 3 , as a specific embodiment of the material distribution device provided by the present invention, the driving mechanism 2 includes a driving assembly 21, a driving wheel 22, a driven wheel 23 and a belt 24; the driving assembly 21 is connected to the driving shaft 31, The driving shaft 31 is also pierced with the driving wheel 22, and the driving shaft 31 is fixedly connected with the driving wheel 22, and the driving wheel 22 is connected with the driven wheel 23 through the belt 24, so The driven wheel 23 is also pierced on the driven shaft 32 , and the driven shaft 32 is fixedly connected with the driven wheel 23 .

[0052] Furthermore, please also refer to figure 2 and image 3 , as a specific implementation of the material distribution device provided by the present invention, the drive assembly 21 includes a drive motor 211, a first sprocket 212, a second sprocket 213 and a sprocket belt 214; the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com