A method for producing keratinase

A keratinase content technology, applied in the field of microorganisms and fermentation, can solve the problems of low fermentation enzyme activity and high fermentation cost, and achieve the effects of good fermentation repeatability, increased keratinase production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Strain culture and fermentation

[0046] 1. Bacterial culture method

[0047] Strain activation: Take out the keratinase-producing Bacillus subtilis WB600-pP43NMK-ker from the -80°C refrigerator (the strains are described in "Biotransformation of keratin waste to aminoacids and active peptides based on cell-free catalysis" by Zheng Peng et al.) Glycerol tubes were streaked in solid LB medium and incubated at 37°C for 14-16h.

[0048]First-class seed liquid culture: pick a single colony from the plate and inoculate it in 3 mL of LB medium, and cultivate overnight at 37°C and 220 rpm.

[0049] Secondary seed liquid culture: transfer the primary seed liquid to a 250 mL Erlenmeyer flask containing 50 mL of LB medium at 2% inoculum, and cultivate at 37°C and 220 rpm for 4-6 hours.

[0050] Shake flask fermentation culture: the OD 600 The secondary seed liquid of 0.8 was transferred to a 250 mL conical flask containing 50 mL of fermentation medium at an inoculat...

Embodiment 2

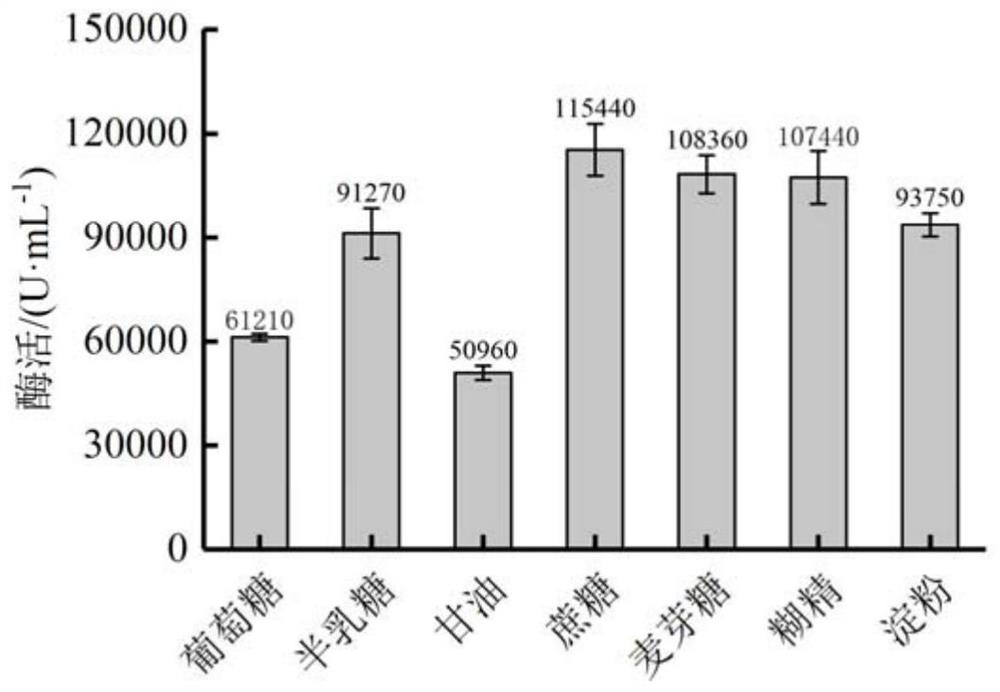

[0051] Example 2: Preparation of keratinase using media containing different carbon sources

[0052] (1) Selection of the optimal carbon source

[0053] Initial fermentation medium components (g / L): glucose 20, yeast powder 10, peptone 20, Na 2 HPO 4 ·12H 2 O 6, KH 2 PO 4 3. MgSO 4 ·7H 2 O 0.3.

[0054] Keep other components of the fermentation medium unchanged, replace glucose with galactose, glycerol, sucrose, maltose, dextrin and starch as carbon sources, and the addition amount is 20g / L; according to Example 1, carry out shake flask fermentation culture for 24h, and measure The enzyme activity of the fermentation broth determines that the best carbon source is sucrose ( figure 1 ).

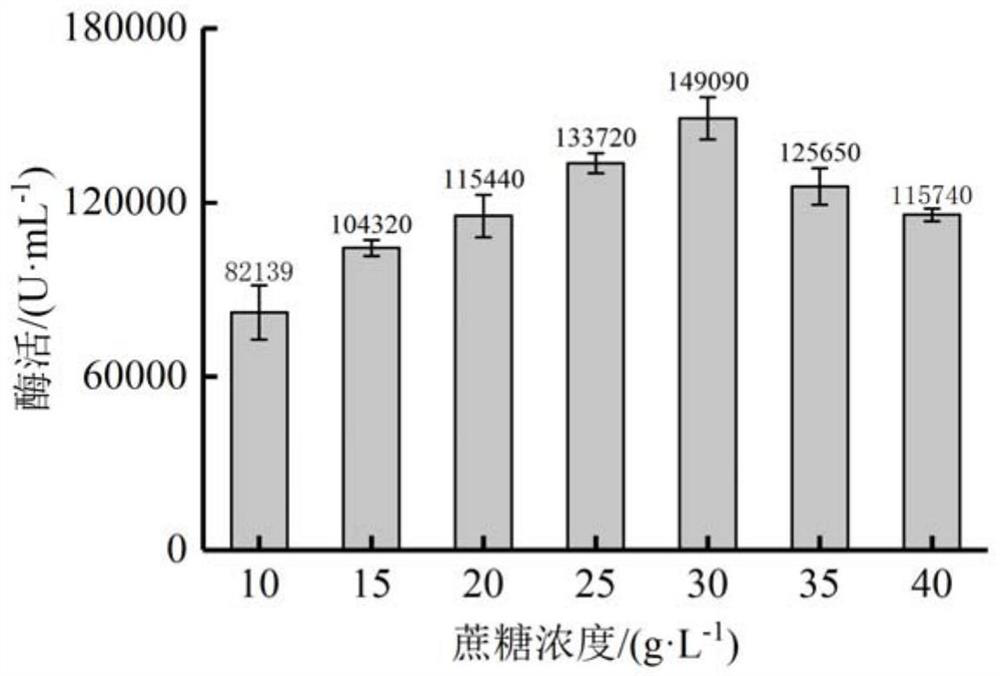

[0055] (2) Selection of carbon source concentration

[0056] The specific embodiment is the same as the above-mentioned step (1), the difference is that the carbon source in the fermentation medium is replaced with sucrose (10, 15, 20, 25, 30, 35, 40g / L) of different concentrations;...

Embodiment 3

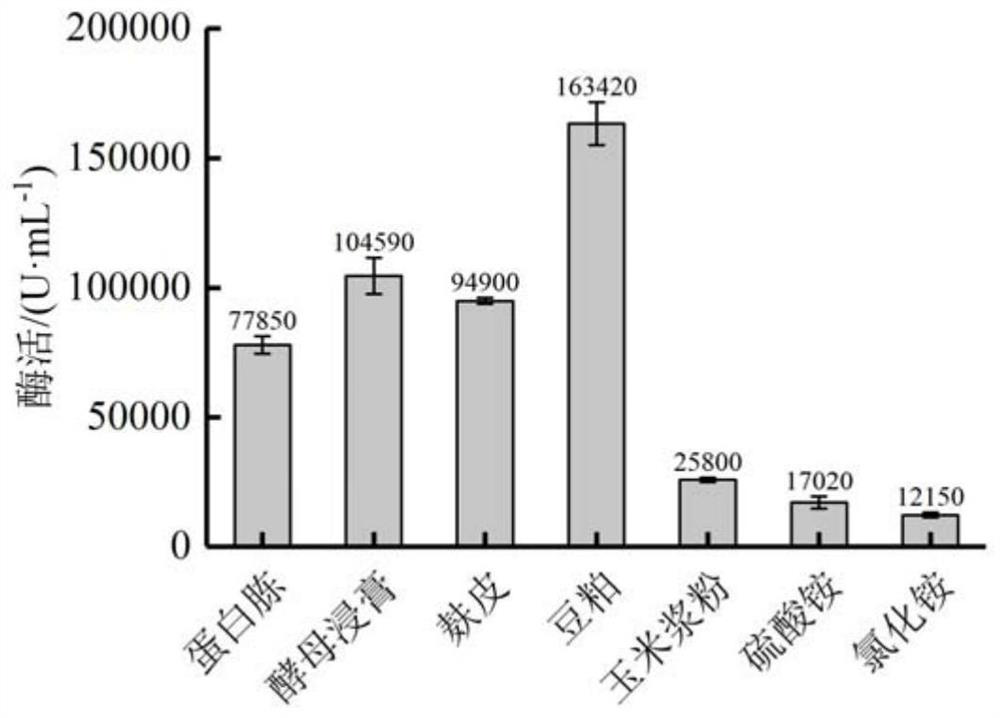

[0057] Example 3: Preparation of keratinase using media containing different nitrogen sources

[0058] (1) Selection of the first nitrogen source

[0059] After determining the optimal carbon source, the yeast powder and tryptone in the fermentation medium were replaced with a single nitrogen source. The single nitrogen source was peptone, yeast extract, bran, soybean meal, corn steep liquor meal, ammonium sulfate and ammonium chloride. Any one, the addition amount is 30g / L; According to embodiment 1, carry out shaking flask culture 24h, measure the enzyme activity of fermentation broth, determine that the best nitrogen source is soybean meal ( image 3 ).

[0060] (2) Selection of the concentration of the first nitrogen source

[0061] The specific embodiment is the same as the above step (1), the difference is that the yeast powder and tryptone in the culture medium are replaced with soybean meal of different concentrations (20, 25, 30, 35, 40, 45, 50g / L); When the enzyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com