Column and beam connecting device

A connecting device and column-beam technology, which is applied in the direction of architecture and building construction, can solve the problems of weak connection reliability and connection strength, and achieve the effect of improving reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

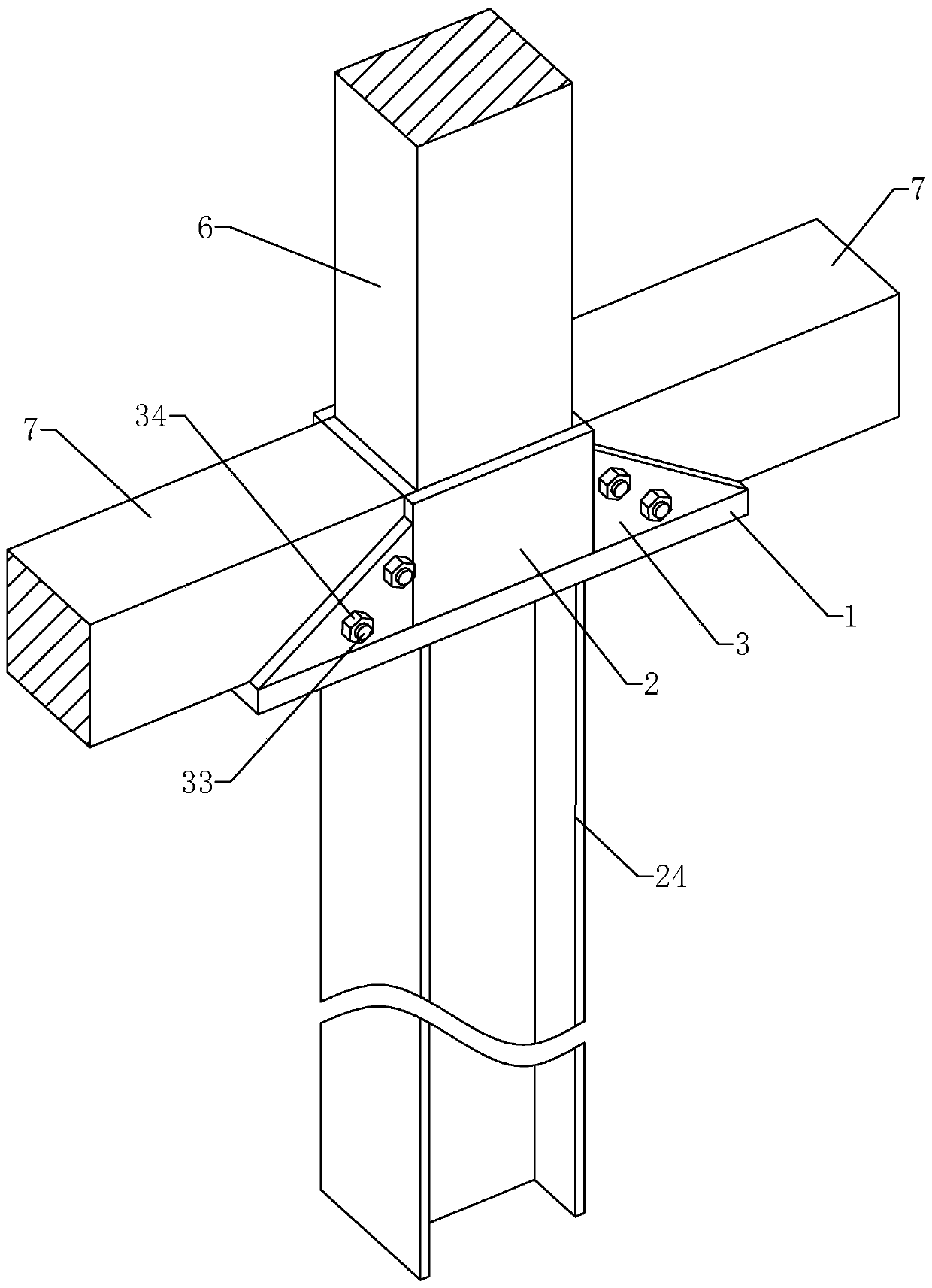

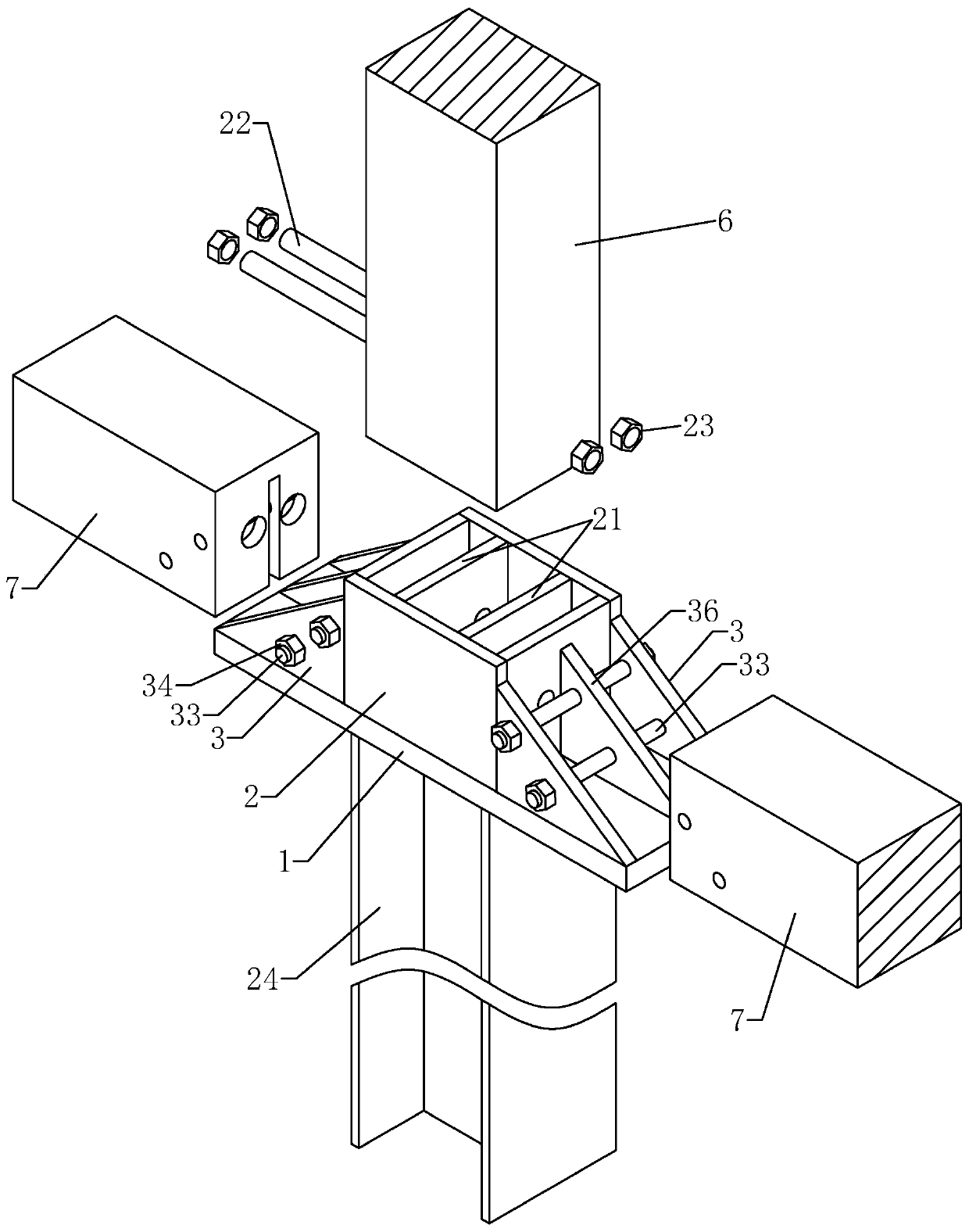

[0035] Example 1: Reference figure 1 and figure 2 , a column-beam connecting device, comprising a steel base plate 1, a steel hoarding plate 2 fixed on the steel base plate 1 by welding and used for fixing a column 6, and a splint 3 fixed on the steel base plate 1 by welding for fixing a beam 7 , the steel hoarding 2 can be a square frame, a round frame or other shapes, the steel hoarding 2 has the same cross-sectional shape as the column 6, the column 6 is located inside the steel hoarding 2, and the beam 7 is located outside the steel hoarding 2; One or more crossbeams 7 can be arranged on the steel bottom plate 1, one crossbeam 7 corresponds to two splints 3, and the two splints 3 clamp the crossbeam 7 in the middle. A first screw 22 is pierced on the steel hoarding 2 along a direction perpendicular to the column 6, the first screw 22 runs through the column 6 and the steel hoarding 2, and a first lock cap 23 is threaded at both ends of the first screw 22 , so that the c...

Embodiment 2

[0037] Example 2: Reference figure 1 and figure 2 , a column-beam connecting device, on the basis of Embodiment 1, also includes a steel inserting plate 21 arranged on the inner side of the steel enclosure 2, the steel inserting plate 21 is fixed on the steel bottom plate 1, and the fixing method can be welded or riveted . A slot is provided on the column 6, and the steel plate 21 is plugged on the column 6 through the slot, and the first screw 22 is inserted on the steel plate 21 and the column 6 at the same time. A positioning block 36 is fixedly arranged on the steel base plate 1 by welding, and the positioning block 36 is located between the two splints 3 and corresponds to the beam 7 one by one. The second screw rod 33 passes through the positioning block 36 at the same time, and the positioning block 36 is inserted into the On the beam 7 , the positioning block 36 further restricts the lateral displacement of the beam 7 , and the second screw 33 passes through the pos...

Embodiment 3

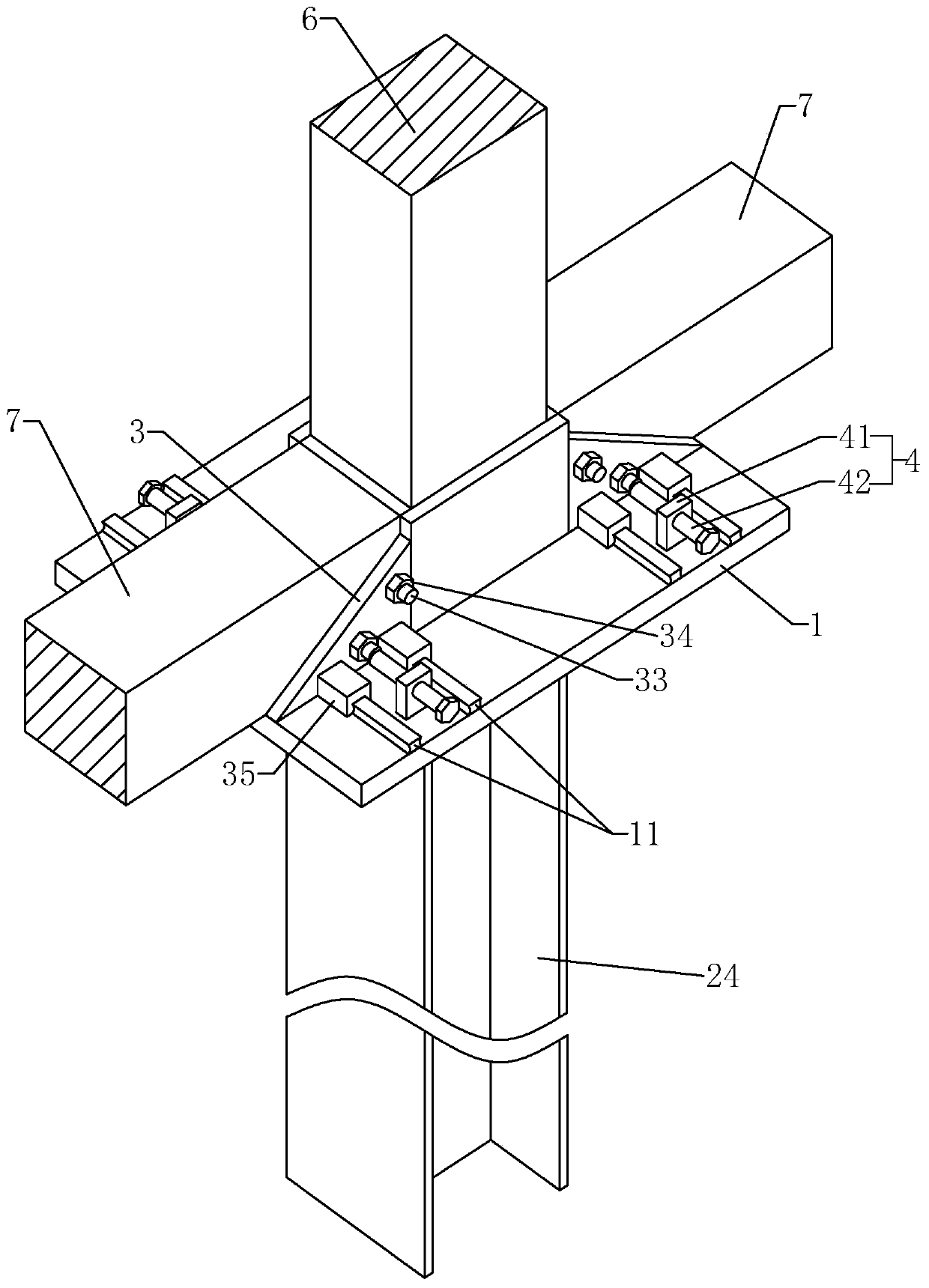

[0038] Example 3: Reference image 3 , a column-beam connection device, the difference from Embodiment 1 and Embodiment 2 is that the connection mode between the splint 3 and the steel floor 1 is different. The limit rail 11 is welded on the steel base plate 1 in a direction perpendicular to the crossbeam 7, and the splint 3 is welded with a sliding sleeve 35 that slides and is connected to the limit rail 11. The limit rail 11 limits the splint 3 to only extend the limit rail. The longitudinal direction of 11 slides, and can not disengage from limit rail 11. Such setting is convenient for on-site installation, so that the splint 3 can clamp the beams 7 of different sizes.

[0039] refer to image 3 , The limit component 4 is also set on the steel bottom plate 1, and the limit component 4 is used to fix the position of the splint 3 after sliding. The limit assembly 4 includes a limit block 41 fixed on the steel base plate 1, a limit rod 42 threaded on the limit block 41 alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com