A pump in the middle water inlet pipe

A water inlet pipe and water inlet technology, applied in the direction of pumps, pump components, pump devices, etc., can solve the problems of inconvenient operation of valves at the water outlet, occupying a large area, and occupying a large space for motors, which is beneficial to operation and maintenance, and reduces manufacturing costs. cost, and the effect of improving water intake efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

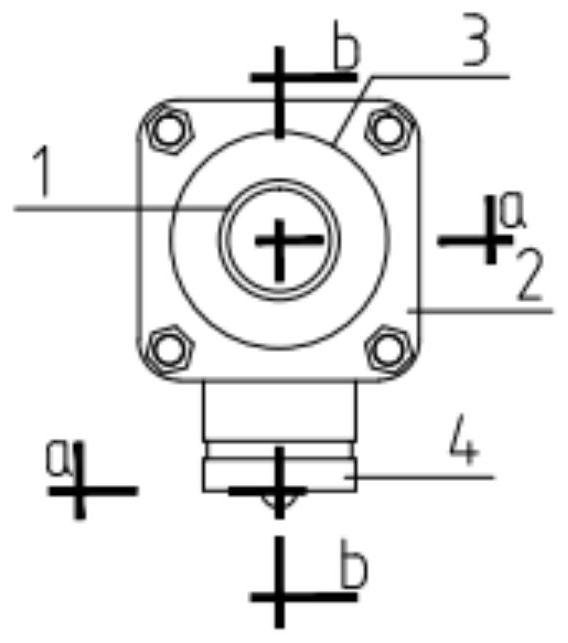

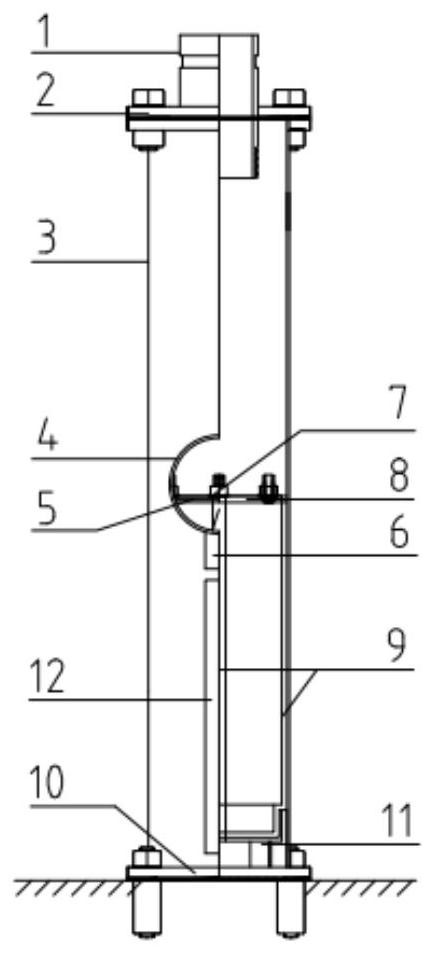

[0041] combined with Figure 1~4 , this embodiment is a single-stage pump body structure with a conventional vertical installation method. The connection relationship and related structure of each component from top to bottom are: the upper end of the water outlet transfer interface 1 is provided with a groove for connecting external pipes, and the water outlet The lower end of the adapter 1 is provided with a threaded interface for connecting to the deep well submersible pump. The middle part of the water outlet adapter 1 is welded with an inner and outer flange 2, through which the inner and outer flange 2 and the fastening seal (bolt) and the casing 3 are connected. The top is connected, and the outer wall of the middle part of the casing 3 has a round hole and is welded with a radial water inlet 4. The water inlet 4 is a horizontal pipe with a groove connection. Divide the water inlet section into two parts, upper, lower, and lower, and weld the diversion partition 5. Thre...

Embodiment 2

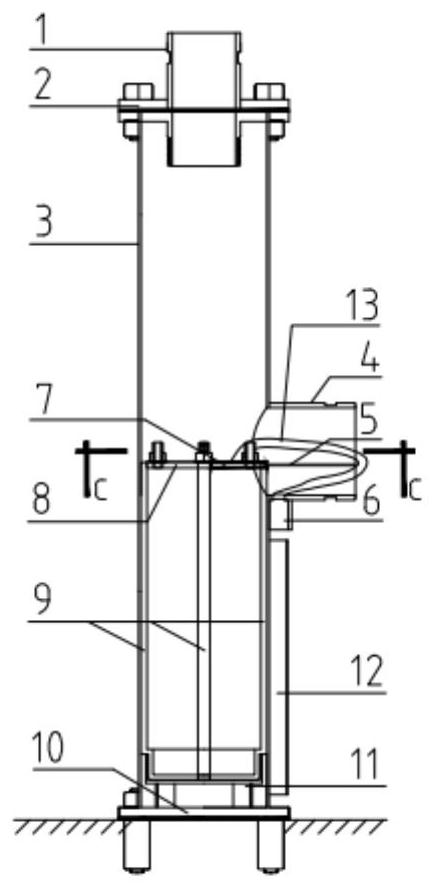

[0043] combined with Figure 5-8, this embodiment is a two-stage pump body structure in a vertical semi-buried installation mode. The connection relationship of each component from top to bottom and the related structure are: the upper end of the water outlet transfer interface 1 is provided with a groove for connecting external pipes, The lower end of the water outlet transfer interface 1 is provided with a threaded interface for connecting the deep well submersible pump. The middle part of the water outlet transfer interface 1 is welded with an annular plate, and the outer ring of the annular plate is welded to the upper end of the pump casing 31. The pump casing 31 is set in the deep well. Outside the pump body of the submersible pump, the outer wall of the lower part of the casing 31 of the pump body is perforated and welded with a radial water inlet 4. The water inlet 4 is a horizontal pipe with a groove connection. There is a diversion baffle 5 that divides the water inl...

Embodiment 3

[0045] combined with Figure 9-15 , this embodiment is an ordinary vertically installed three-stage pump body structure, and the advantage of this structure is that it is more convenient for large-scale mass production. In this embodiment, the original water inlet 4 is made into a three-way water inlet 41 in the form of a tee with different diameters. Both ends of the main pipe of the three-way water inlet 41 are welded with a circular seal ring with a sealing surface, and through the pump casing casing 31 and the inner circle and outer flange 2 of the motor sleeve 32, 4 long bolts and two sealing rings to fix the tee water inlet 41 between the pump body sleeve 31 and the motor sleeve 32, and the end blind plate 10 Change it to a flanged end blind plate 14, which is fixed to the ground by expansion bolts and shock absorbing pads. Now because the motor leads are positioned in mid-air, on the outlet hole 6 one side, the outer wall of the motor casing 32 increases the metal wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com