High-coupling air-core split reactor

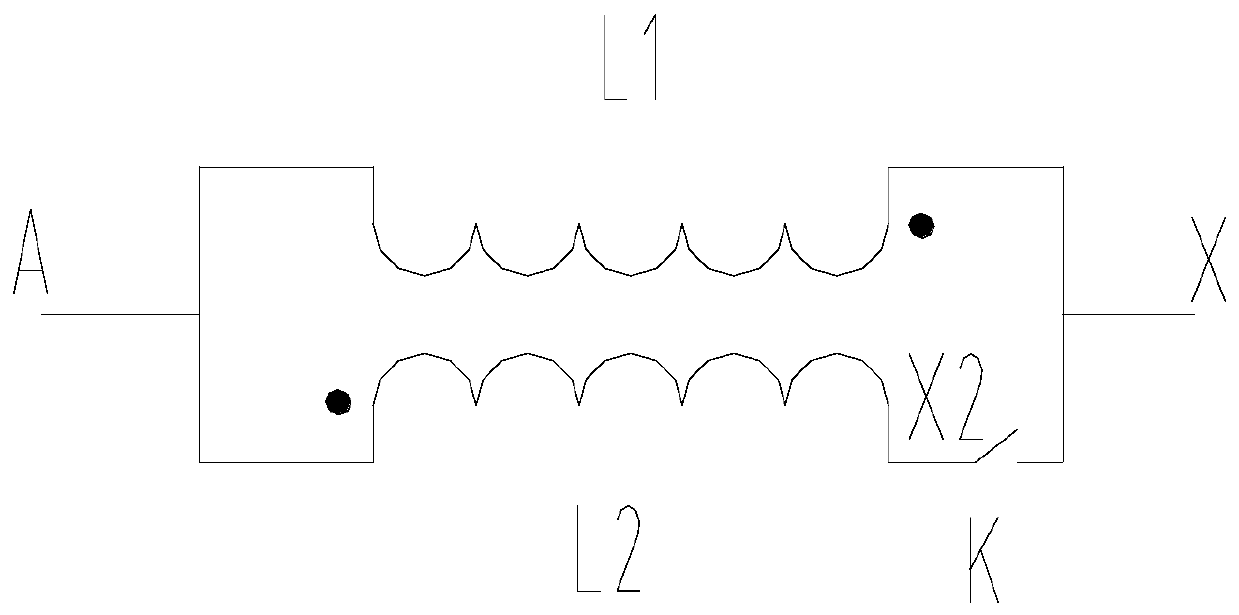

A split reactor and high-coupling technology, which is applied in signal inductors without magnetic cores, transformer/inductor coils/windings/connections, circuits, etc., can solve problems such as large insulation distances and reduce the coupling coefficient of two sets of coils , to achieve the effect of resolving the contradiction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

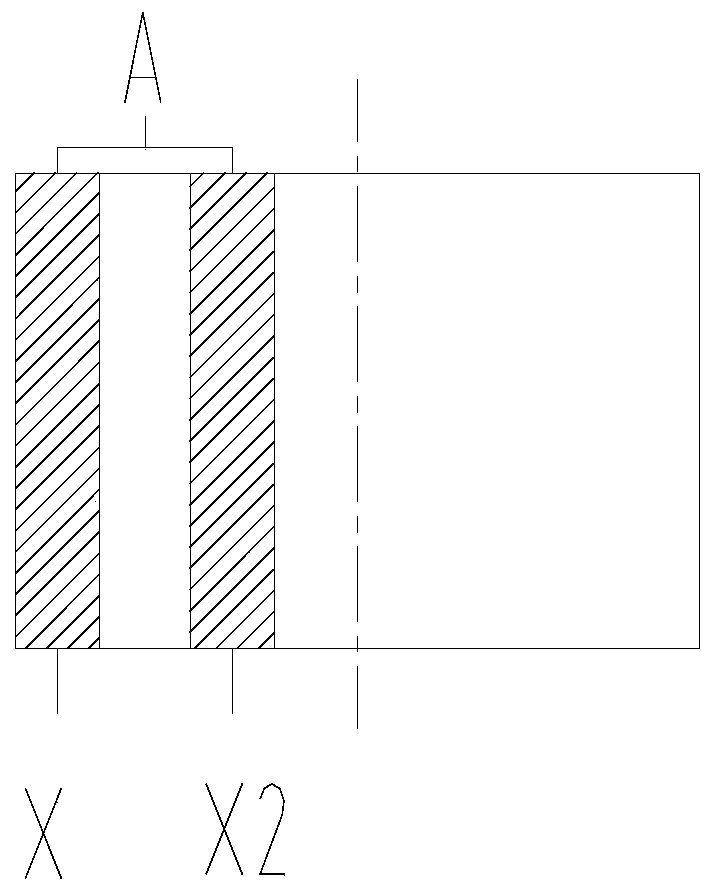

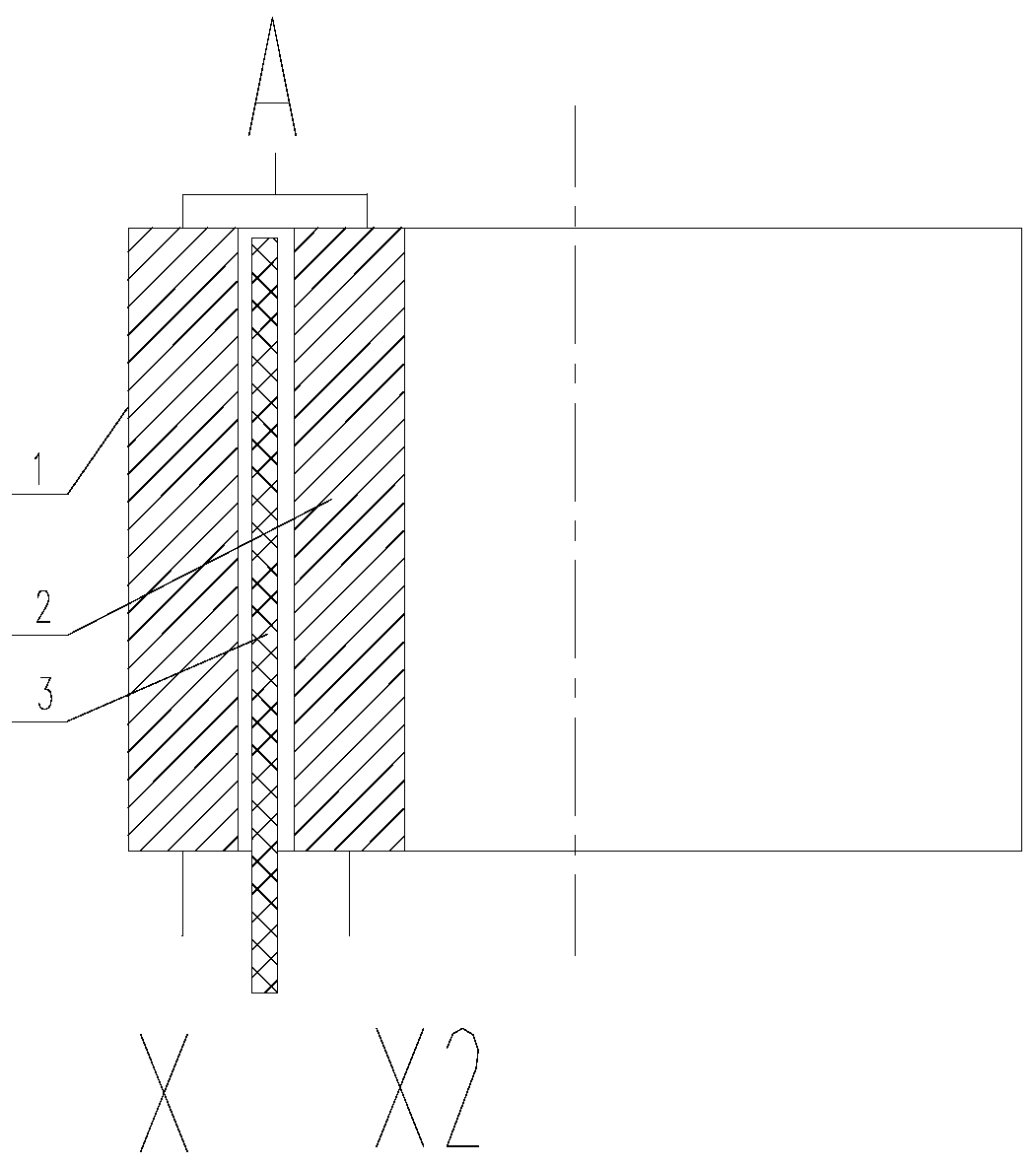

[0016] refer to image 3 , Figure 4 with Figure 5 , this embodiment provides a high-coupling air-core split reactor, including a cylindrical first winding 1 and a second winding 2 whose outer diameter is smaller than the inner diameter of the first winding 1, and the first winding 1 and the second winding 2 are concentrically socketed A cylindrical insulating barrier 3 is provided between the first winding 1 and the second winding 2, the lower end of the cylindrical insulating barrier 3 is longer than the first winding 1 and the second winding 2, and the upper ends of the first winding 1 and the second winding 2 are common The lower end of the first winding 1 and the second winding 2 is a split outlet end; there is an incoming terminal block 4 and the upper part of the first winding 1, the second winding 2 and the insulation barrier 3 Connection, the first outgoing terminal row 5 is connected to the lower part of the first winding 1, the second outgoing terminal row 6 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com