Motor

A technology of motors and winding sleeves, which is applied in the field of motors, can solve problems affecting the operation of motors, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

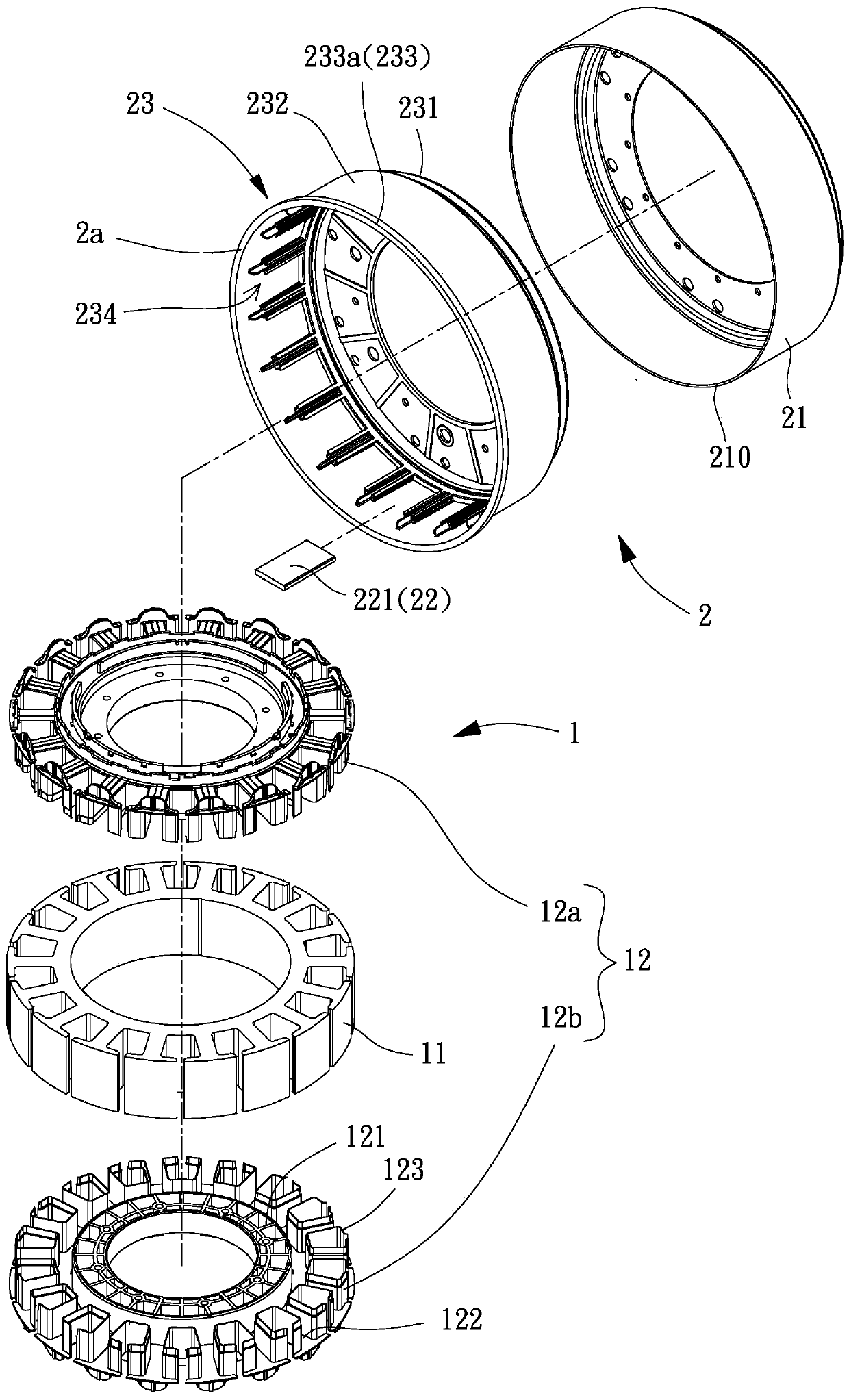

[0059] Please refer to figure 1 As shown, it is the first embodiment of the motor of the present invention, which includes a stator 1 and a rotor 2, and the ring of the rotor 2 is set on the outer periphery of the stator 1.

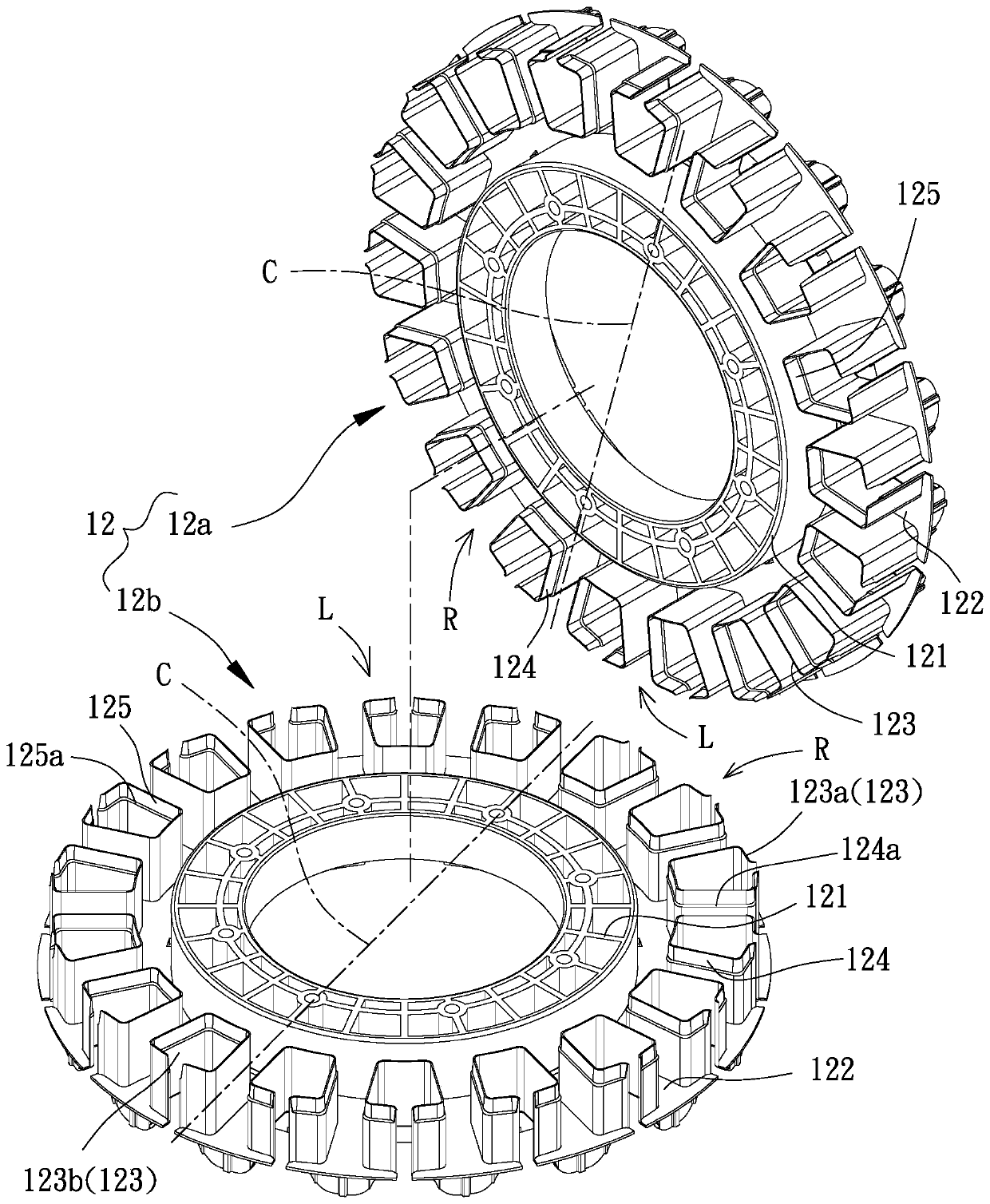

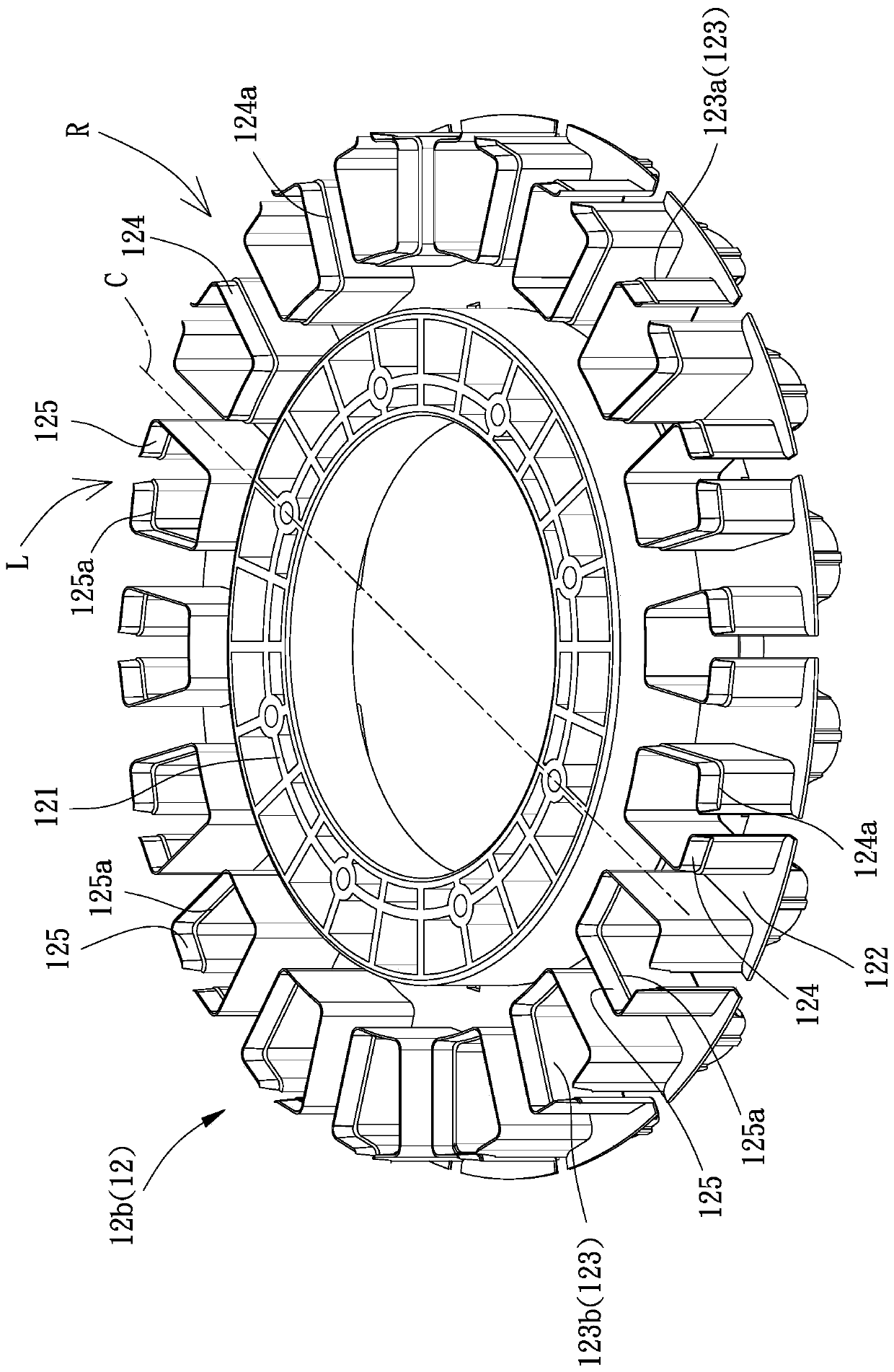

[0060] The stator 1 has an iron core 11 and a winding sleeve 12, and the iron core 11 can be axially stacked by a plurality of silicon steel sheets to a predetermined thickness. In addition, the winding set 12 can be formed by wrapping the iron core 11 in one piece, or can be combined with the iron core 11 by upper and lower winding sets respectively; in this embodiment, the winding set 12 can be There is an upper winding sleeve 12a and a lower winding sleeve 12b, the upper winding sleeve 12a and the lower winding sleeve 12b can be made of plastic material, and the lower end of the upper winding sleeve 12a and the lower winding sleeve The upper ends of the sleeves 12b are preferably overlapped to cover the iron core 11 together, so as to ensure that ther...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap