Circuit board roll-leveling device and using method thereof

A circuit board and rolling device technology, which is applied in printed circuit, printed circuit manufacturing, printed circuit secondary processing, etc., can solve the problem of huge cost of consumables, and achieve the effect of saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical features adopted by the present invention to achieve the predetermined creation purpose are further described below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

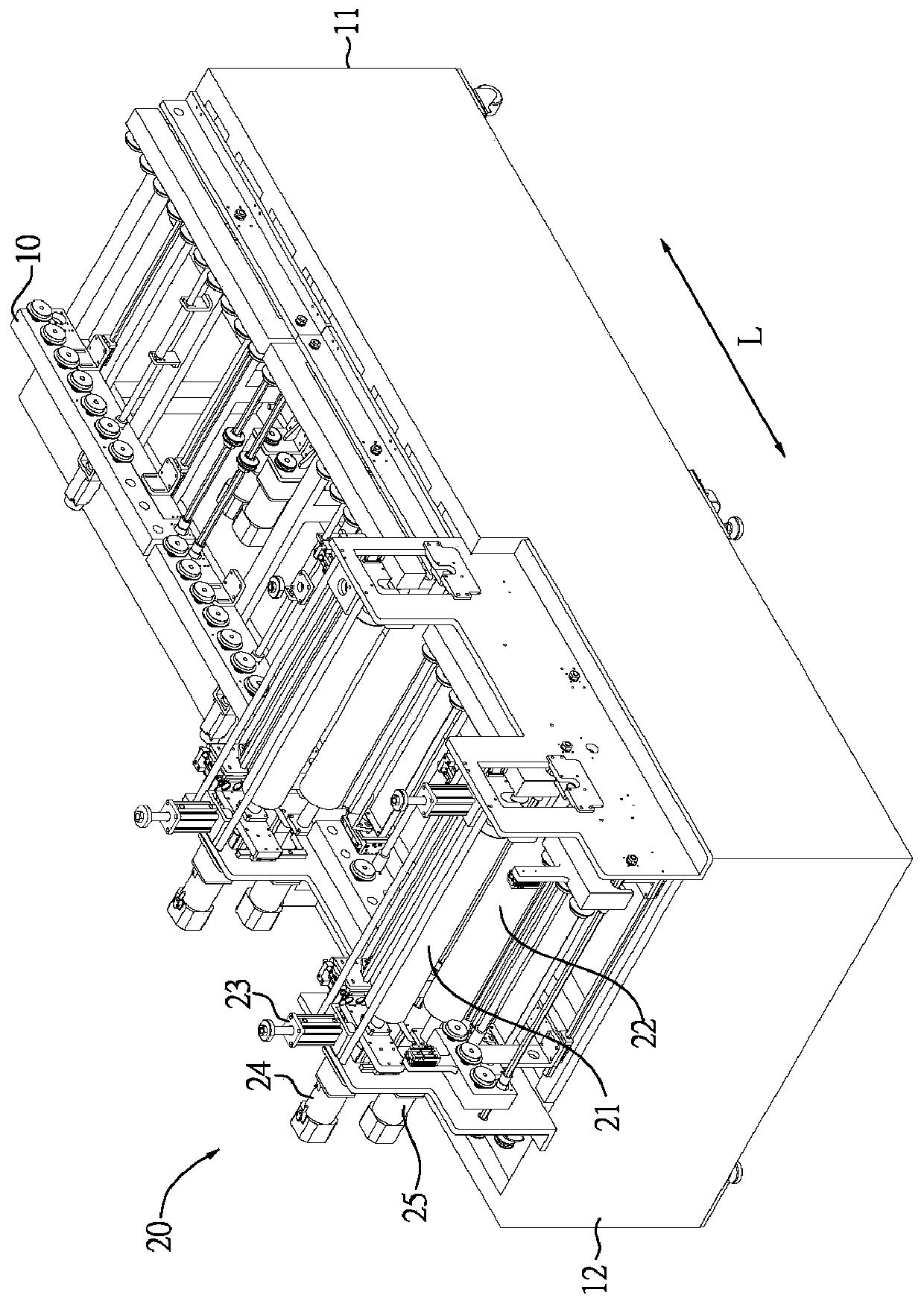

[0053] see figure 1 As shown, the circuit board rolling device of the present invention includes a conveying track 10, a rolling component 20 and at least one ink removal device.

[0054]The conveying track 10 extends along a conveying direction L, and opposite ends thereof along the conveying direction L are a front end 11 and a rear end 12 respectively.

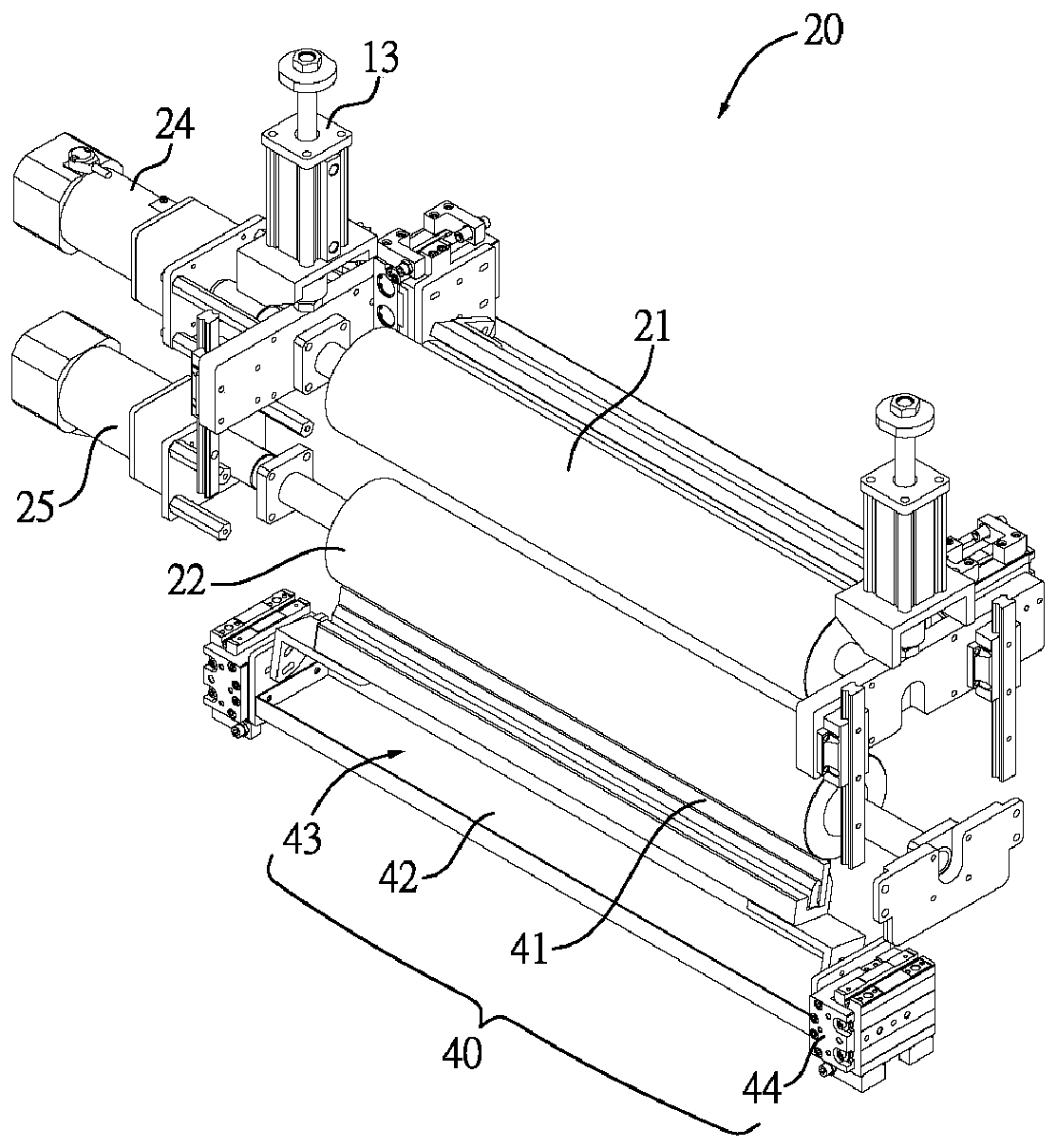

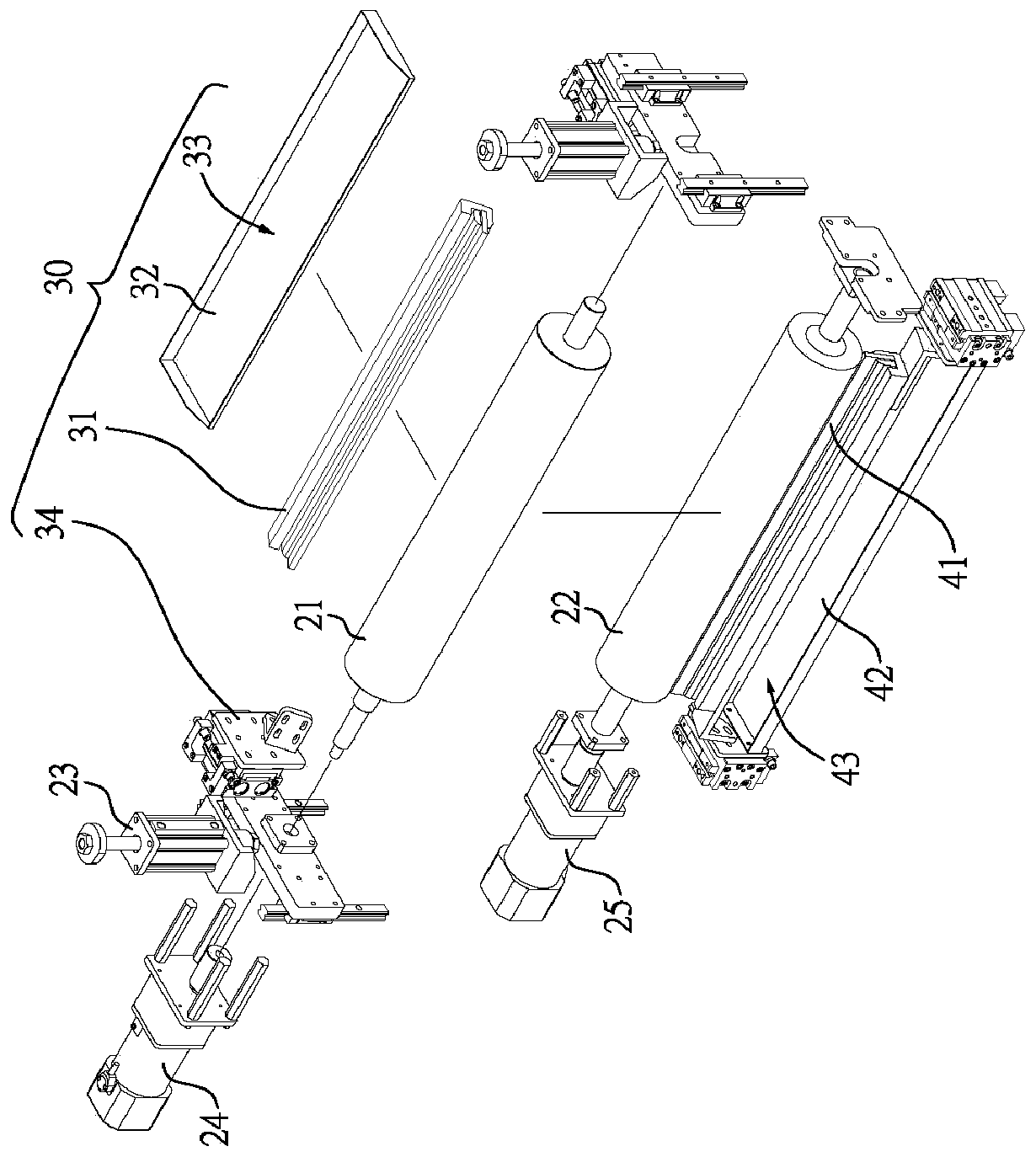

[0055] see figure 1 and figure 2 As shown, the rolling assembly 20 includes an upper roller 21, a lower roller 22, a mobile power unit 23, an upper roller rolling device 24 and a lower roller rolling device 25, and the upper roller 21 and the upper roller rolling device 24 are arranged on the conveying track 10 The upper roller rolling device 24 can drive the upper roller 21 to rotate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com