Impeller press fitting height adjusting device

A technology of height adjustment and impeller, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high test efficiency and inconvenient adjustment of impeller pressing height, and achieve the effect of improving test efficiency, simple structure and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

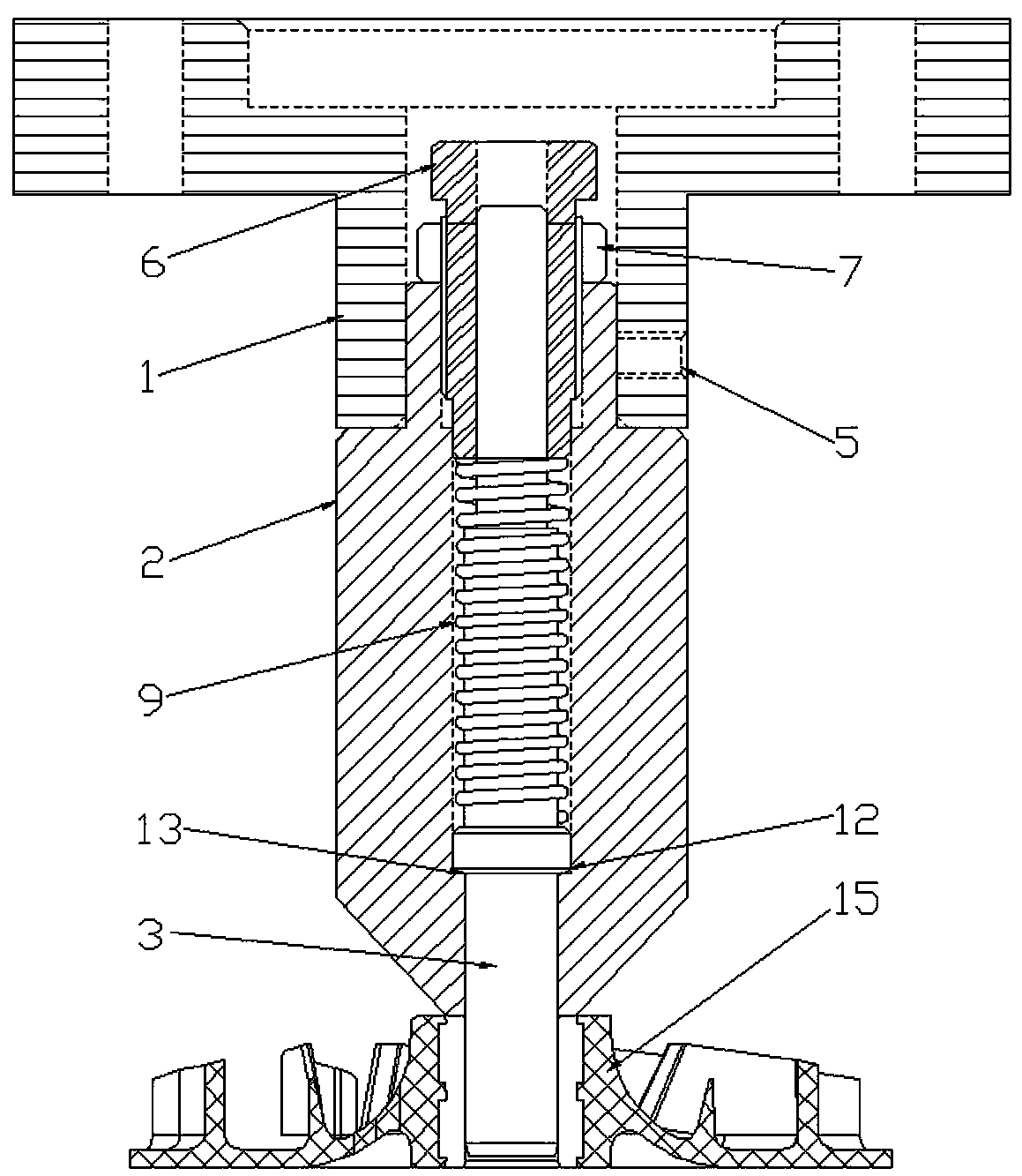

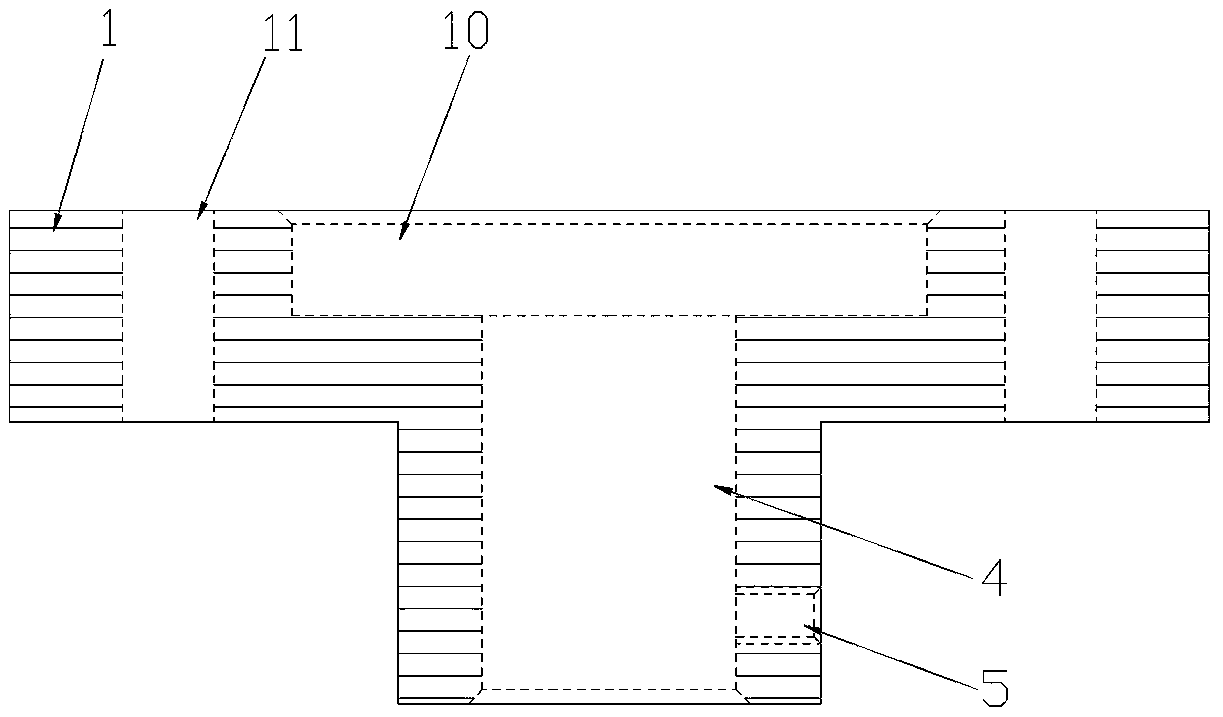

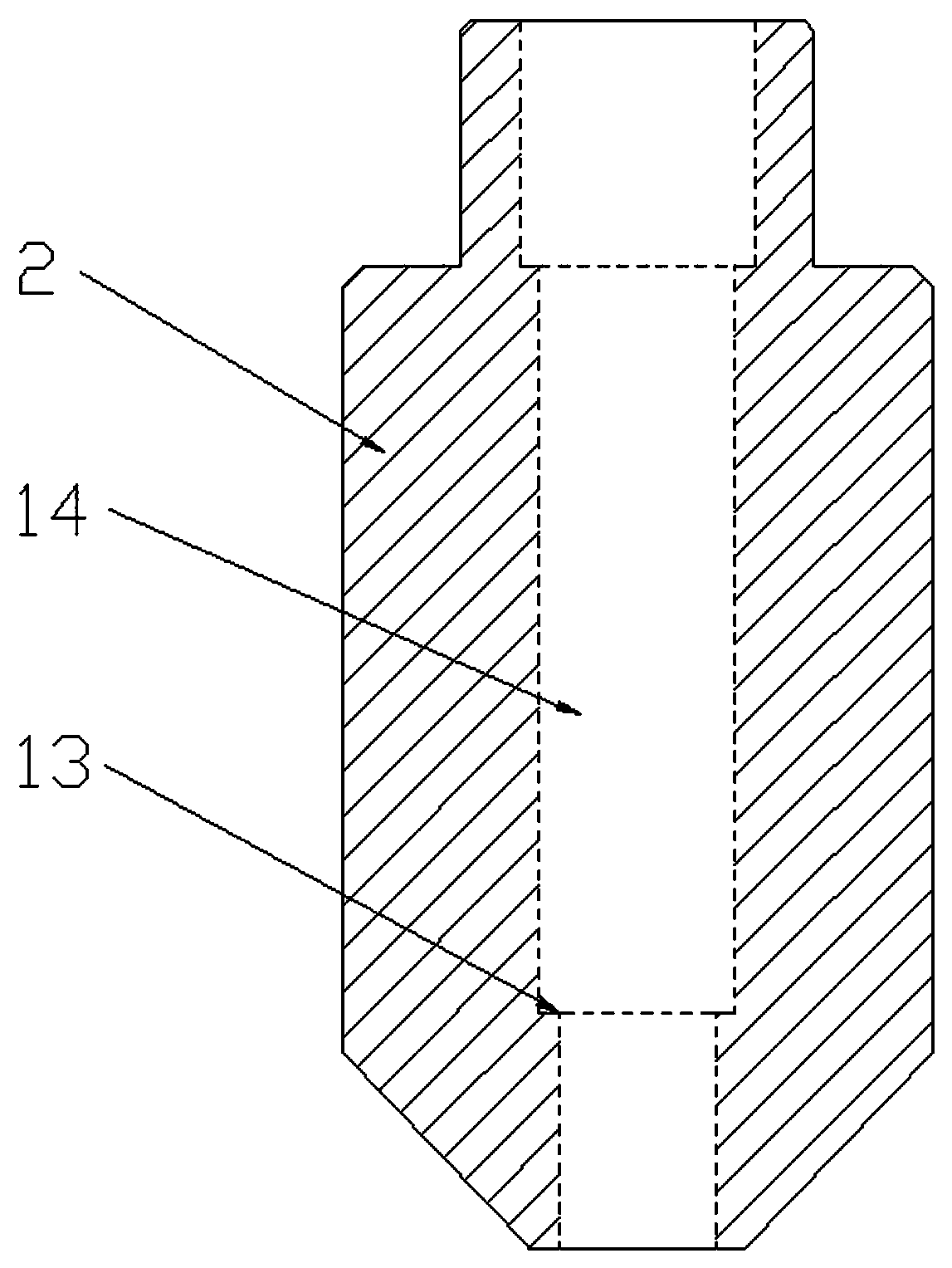

[0029] Such as Figure 1-5 As shown, a device for adjusting the height of an impeller by press-fitting includes a connection plate 1, a pressure head 2 and a fixed core 3. The bottom of the connection plate 1 is connected with a pressure head 2, and a through hole 14 is provided in the pressure head 2. , the upper part of the through hole one 14 is provided with threads, and the upper part of the through hole one 14 is threadedly connected with an adjustable nut 6. When in use, the indenter and the connecting plate have a clearance fit, and the pressure can be adjusted by rotating the adjustable nut. High height, simple structure, convenient adjustment, no need to remake related equipment, reduce the workload of the staff, save time, improve the test efficiency and save costs in the test products that need frequent adjustment. The outside of the adjustable nut 6 is provided with threads, and the outside of the adjustable nut 6 is threadedly connected with a lock nut 7. When in...

Embodiment 2

[0032] Such as Image 6 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that a sealing ring 8 is provided at the connection between the bottom of the fixed core 3 and the impeller 15, and when in use, the gap between the fixed core and the impeller can be increased. The friction between the impellers can be fixed on the fixed core under the friction force.

Embodiment 3

[0034] Such as Figure 7 As shown, the structure of this embodiment is basically the same as that of Embodiment 2, the difference is that: the through hole 2 4 is provided with an internal thread, the upper part of the pressure head 2 is provided with an external thread, and the pressure head 2 is threaded It is fixed on the bottom of the connection plate 1, and it is convenient to disassemble and install the connection plate and the indenter when in use, and it is convenient to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com