Pavement structure and method of colored greenway

A color and greenway technology, applied to the coagulation pavement, roads, roads and other directions paved on site, can solve the problems of complicated construction and undurable color greenway pavement structure, improve crack resistance and solve interface stickiness. knot problem, the effect of improving the bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Further preferably, the colored modified epoxy resin is prepared by the following method.

[0029] Preferably, the embodiment of the present invention also provides a preparation method of a colored modified epoxy resin. The method comprises the steps of:

[0030] S01. Weigh each component material according to the above-mentioned color modified epoxy resin;

[0031] S02. Premixing the silane coupling agent with the nano diatomaceous earth to obtain a first mixture;

[0032] S03. Preheating epoxy resin, adding the first mixture into the preheating epoxy resin, fully mixing, then adding the diluent, the stabilizing agent, and the defoamer in turn, mixing and stirring at 70 Incubate at -80°C for 0.5-1h to obtain the colored modified epoxy resin.

[0033] In the above-mentioned step S01, each component material is weighed according to the above-mentioned colored modified epoxy resin, which is consistent with the above-mentioned discussion. In order to save space, detail...

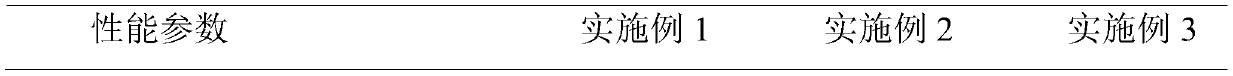

Embodiment 1

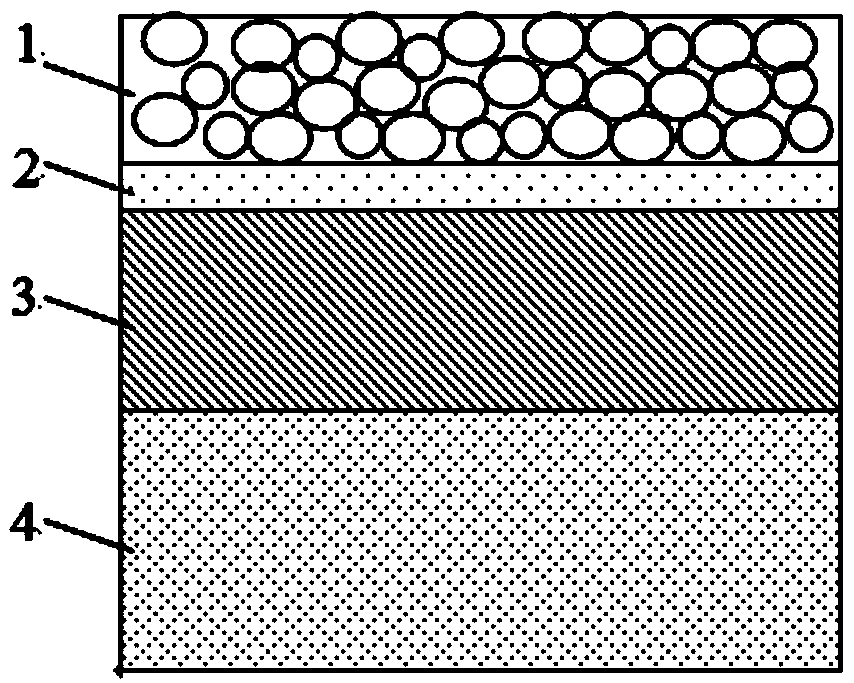

[0064]Use a road roller to roll and finish the original soil subgrade to form a subgrade; select 4% cement-stabilized graded gravel as the non-motor vehicle road base material, and after paving and rolling, the thickness is 30cm; use high-viscosity modified asphalt as anti-seepage For the bonding layer, the amount of spraying is 1.2kg / ㎡, and 0.3-0.6mm gravel is spread synchronously to ensure that the gravel coverage area is about 60%-80%; mix the raw materials of the colored green road surface layer to obtain a mixture, Spread the mixture evenly on the impermeable adhesive layer to ensure that the loose paving thickness is equal to the horizontal line; after the paving length reaches 20m, use the principle of rolling 2 times with a 1-ton small road roller to obtain the obtained product. Describe the colored greenway.

[0065] The raw materials of the colored green road surface layer include 60 parts of coarse aggregate, 30 parts of fine aggregate, 4 parts of filler, 7 parts of...

Embodiment 2

[0068] The original soil subgrade is rolled and polished by a road roller to form a subgrade; 4% cement stabilized graded stone powder slag is selected as the non-motor vehicle road base material, and after paving and rolling, the thickness is 40cm; water-based epoxy resin and water-based curing agent are used After mixing according to the proportion, it will be used as an impermeable bonding layer, and the spraying amount is 0.6kg / ㎡; synchronously spread 0.3-0.6mm gravel to ensure that the gravel coverage area is about 60%-80%; mix the colored green The raw materials of the road surface layer are mixed, and the mixture is evenly spread on the permeable layer to ensure that the loose paving thickness is equal to the horizontal line; after the paving length reaches 20m, the principle of rolling with a 1 ton small road roller is rolled twice , the colored green channel can be obtained.

[0069] Water-based epoxy resin and water-based curing agent are mixed in proportion as an an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com