Colored greenway paving material and preparation method

A pavement material and color technology, applied to roads, roads, pavement details, etc., can solve the problems of poor color durability, prone to "yellowing, poor water permeability, etc., and achieve stable properties, improvement of easy cracking, and strong water permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The above-mentioned colored modified epoxy resin used for colored greenway paving materials is prepared by the following method.

[0042] Correspondingly, the embodiment of the present invention also provides a method for preparing a colored modified epoxy resin used in colored greenway pavement materials. The method comprises the steps of:

[0043] A preparation method for a colored modified epoxy resin for colored greenway paving materials, comprising the steps of:

[0044] S01. Weigh each component substance according to the above-mentioned color modified epoxy resin used for the color greenway pavement material;

[0045] S02. Premixing the silane coupling agent with the nano diatomaceous earth to obtain a first mixture;

[0046] S03. Preheat the epoxy resin, add the first mixture into the preheated epoxy resin, mix evenly by high-speed shearing, then add the toner, the heavy calcium powder, and the microcalcium powder in sequence. After the silicon powder, the di...

Embodiment 1

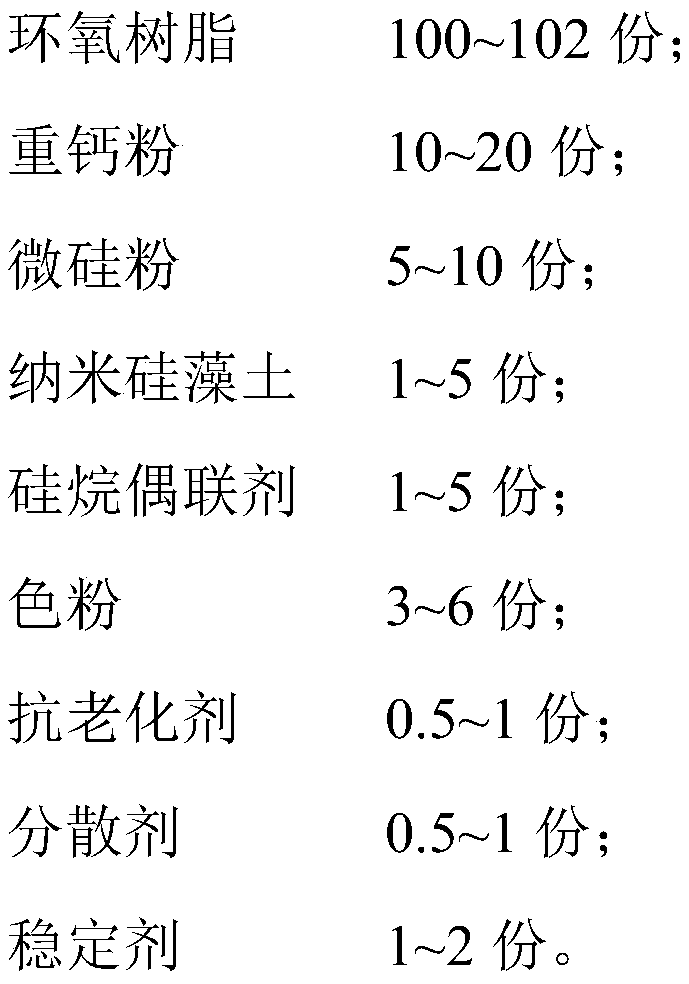

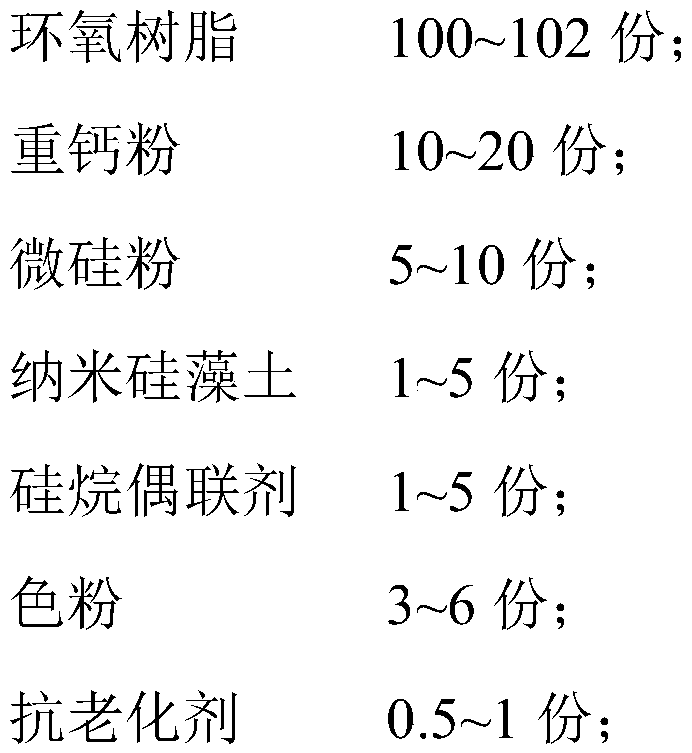

[0074] The colored modified epoxy resin that is used for colored greenway pavement material comprises following components by weight:

[0075] 100 parts of epoxy resin, 10 parts of heavy calcium powder, 5 parts of silica fume, 1 part of nano-diatomaceous earth, 1 part of silane coupling agent, 3 parts of toner, 0.5 parts of anti-aging agent, 0.5 parts of dispersant, stabilizer 1 serving. Wherein, the epoxy resin is E51 epoxy resin; the heavy calcium powder is 600 mesh heavy calcium powder; the microsilica is 600 microsilica; the nano diatomaceous earth is nano diatom soil; the silane coupling agent is a KH-550 coupling agent; the toner is 300 mesh red color toner; the anti-aging agent is a salicylate UV absorber; the dispersion The agent is ethanol; the stabilizer is an ammonium salt cationic surfactant.

[0076] The preparation method of the colored modified epoxy resin that is used for colored greenway pavement material is as follows:

[0077] First, premix the silane cou...

Embodiment 2

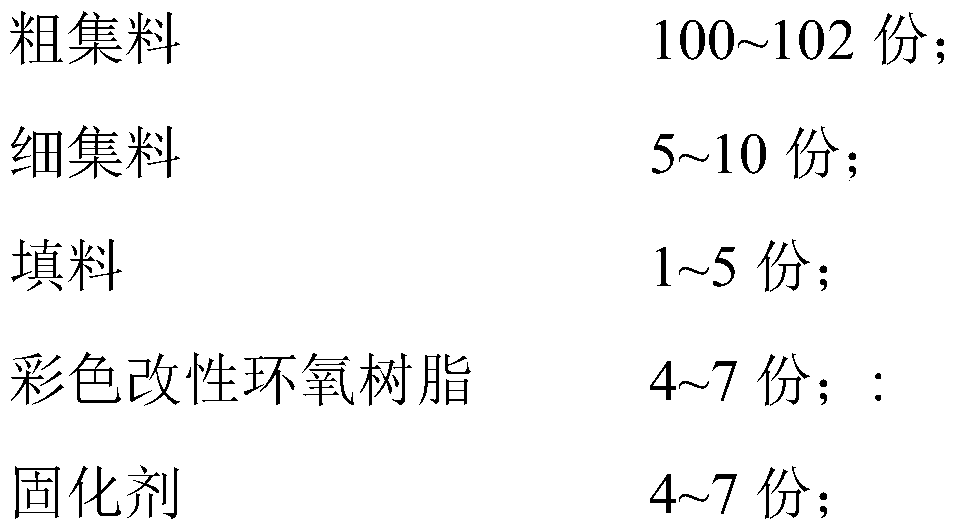

[0079] The colored greenway pavement material comprises the following parts by weight:

[0080] 100 parts of coarse aggregate, 5 parts of fine aggregate, 1 part of filler, 4 parts of colored modified epoxy resin used in colored greenway paving materials prepared in Example 1, and 4 parts of curing agent. Wherein, the coarse aggregate is 3-6mm stone, the fine aggregate is 0-3mm stone, the filler is mineral powder, and the curing agent is an amine curing agent.

[0081] The preparation method of the colored greenway pavement material is as follows: the color modified epoxy resin and curing agent for the colored greenway pavement material prepared in Example 1 are added to the stirring pot according to the mass ratio, and stirred manually or mechanically 3min, then add coarse aggregate and fine aggregate in turn, continue to stir for 2min, finally add filler, continue to stir for 1min, and get the colored green road pavement material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com