Solenoid valve system

A technology of solenoid valve and spool, applied in the field of solenoid valve system, to achieve common use, reduce the number of drives, and realize the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

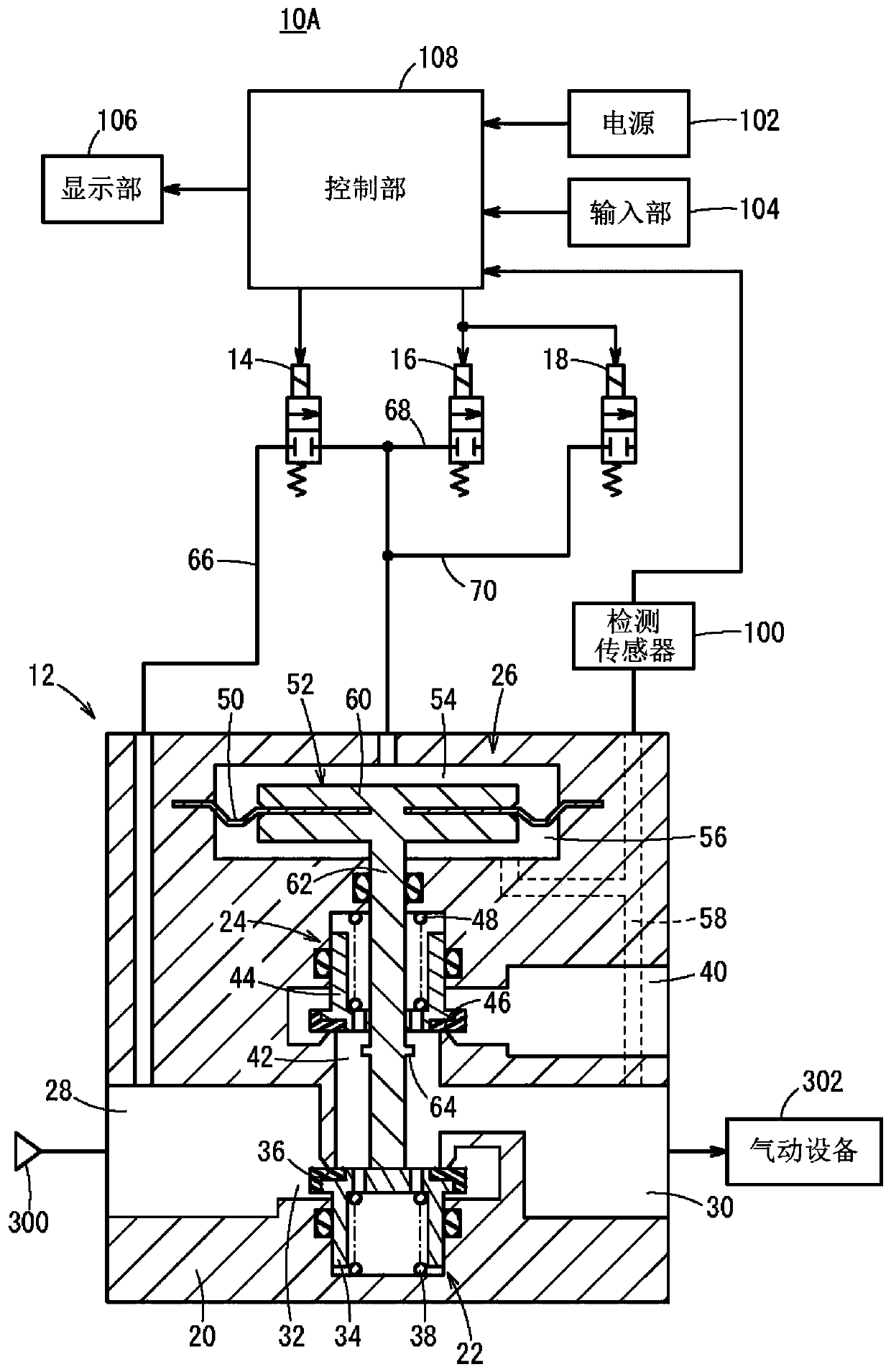

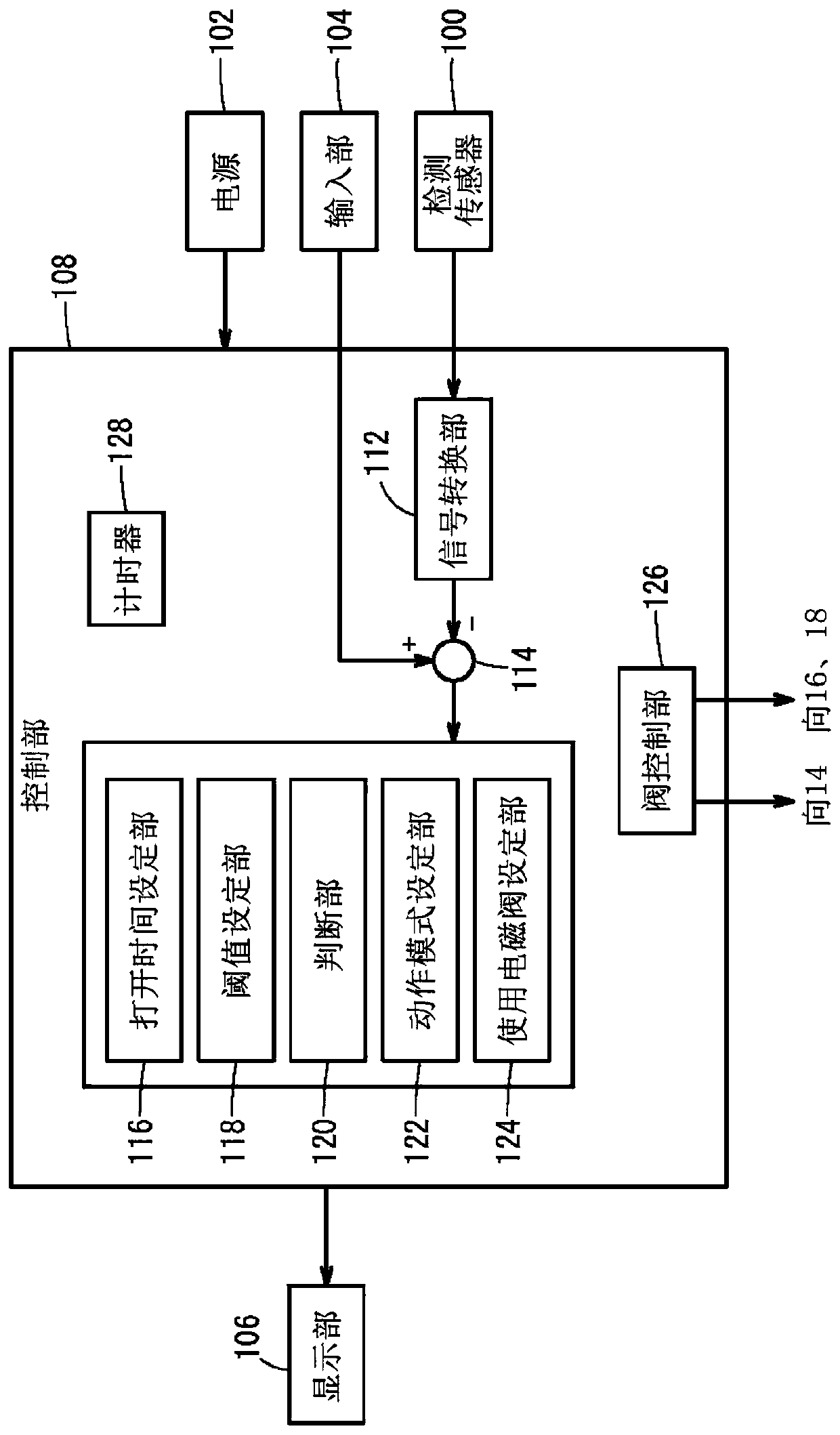

[0024] figure 1 The solenoid valve system of the first embodiment of the invention shown is used, for example, as an electropneumatic regulator for pressure control of the pneumatic device 302 based on an input signal.

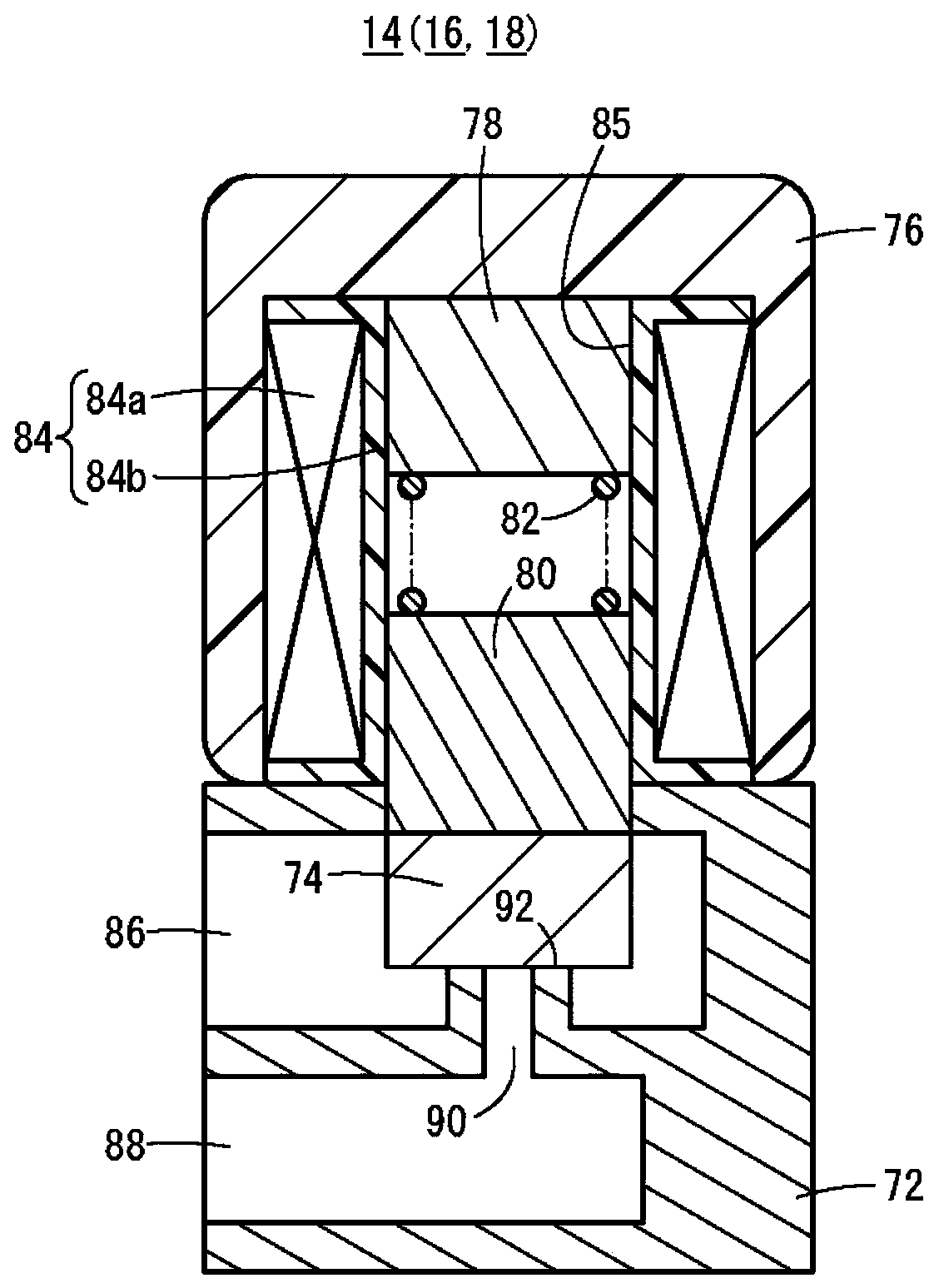

[0025] Such as figure 1 As shown, the solenoid valve system 10A includes a valve main body 12 , an air supply solenoid valve 14 , a first exhaust solenoid valve 16 , and a second exhaust solenoid valve 18 . The valve main body 12 has a valve body 20 , an air supply valve portion 22 , an exhaust valve portion 24 , and a pilot valve portion 26 . A supply flow path 32 that communicates the inlet port 28 and the outlet port 30 with each other is formed in the valve body 20 . A gas supply source 300 for supplying compressed gas (for example, compressed air) is connected to the inlet port 28 . A pneumatic device 302 is connected to the outlet port 30 .

[0026] The air supply valve unit 22 opens and closes the air supply passage 32 . Specifically, the air suppl...

no. 2 approach

[0135] Next, a solenoid valve system 10B according to a second embodiment of the present invention will be described. In this embodiment, the same reference numerals are assigned to the same components as in the first embodiment, and description thereof will be omitted.

[0136] Such as Figure 13 As shown, the solenoid valve system 10B includes a valve body 200 instead of the valve body 12 . The valve main body 200 has a valve body 201 , an air supply valve portion 22 and a pilot valve portion 202 . A supply flow path 32 that communicates the inlet port 28 and the outlet port 30 with each other is formed in the valve body 201 .

[0137] The pilot valve unit 202 is a member for driving the air supply valve element 34 and is provided on the valve body 201 . The pilot valve unit 202 includes a diaphragm 50 that divides a predetermined space formed in the valve body 201 into a pilot chamber 54 and a back pressure chamber 56 , and a spool operating portion 52 provided on the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com